Chip tantalum capacitor and its cathode manganese dioxide layer quality control method

A quality control method, manganese dioxide layer technology, applied in the direction of measuring electrical variables, instruments, measuring electricity, etc., can solve the problems of user quality pressure, economic loss, etc., to improve inherent reliability, promote process optimization, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

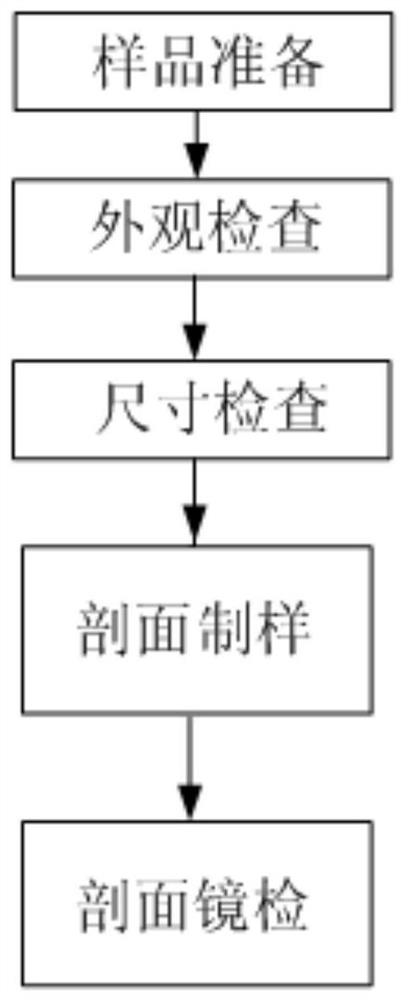

[0033] figure 2 Shown is a flow chart of the quality control method for the cathode manganese dioxide layer of the chip tantalum capacitor according to the preferred embodiment of the present invention.

[0034] see figure 2 , the quality control method of the cathode manganese dioxide layer of the chip tantalum capacitor of this embodiment includes the following steps:

[0035] S11, Sample Preparation

[0036] According to the principle of 2% of the total number of production batches, no less than 5 and no more than 10, samples are obtained.

[0037] S12, visual inspection

[0038] The structure, marks and external surfaces of the samples are examined with a microscope (eg, a 20X magnification microscope). Defect criterion: The content of the sample identification should be clear and complete, the molding encapsulation material should be free of cracks and defects that expose the inner (tantalum core) core, and there should be no stress crack marks on the lead-out end (...

Embodiment 2

[0057] Figure 5 Shown is a flow chart of a quality control method for a chip tantalum capacitor according to a preferred embodiment of the present invention.

[0058] see Figure 5 , the quality control method of the chip tantalum capacitor in this embodiment includes the following steps:

[0059] S21, Sample Preparation

[0060] According to the principle of 2% of the total number of production batches, no less than 5 and no more than 10, samples are obtained.

[0061] S22, Visual inspection

[0062] The structure, marks and external surfaces of the samples are examined with a microscope (eg, a 20X magnification microscope). Defect criterion: The content of the sample identification should be clear and complete, the molding encapsulation material should be free of cracks and defects that expose the inner (tantalum core) core, and there should be no stress crack marks on the lead-out end (positive and negative lead-out ends), and the lead-out end should be coated The str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com