Antifoam composition

The technology of a composition and defoaming agent is applied in the field of fine chemical preparations and defoaming agent compositions with acrylate polymer as the main active substance, which can solve the problems of precipitation residue, environmental damage, etc., and achieves improved foam suppression performance, The effect of increasing the rate of foam breaking, increasing the speed of spreading and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

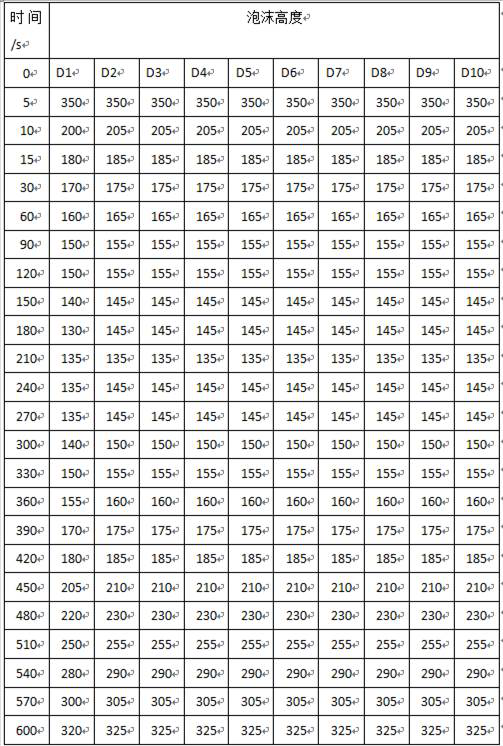

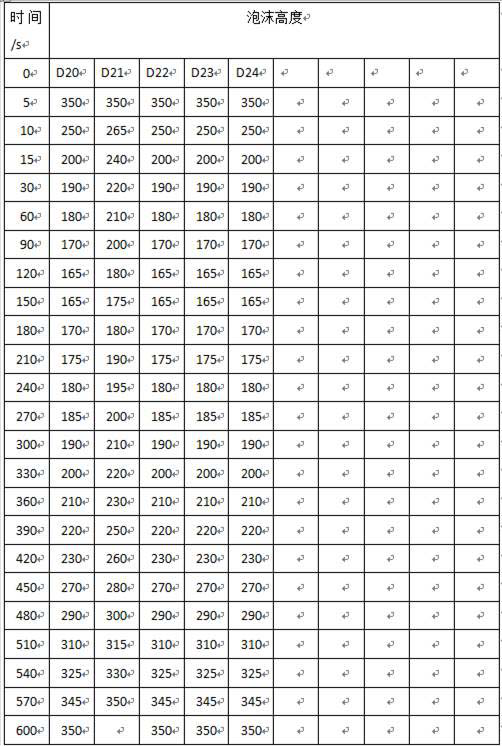

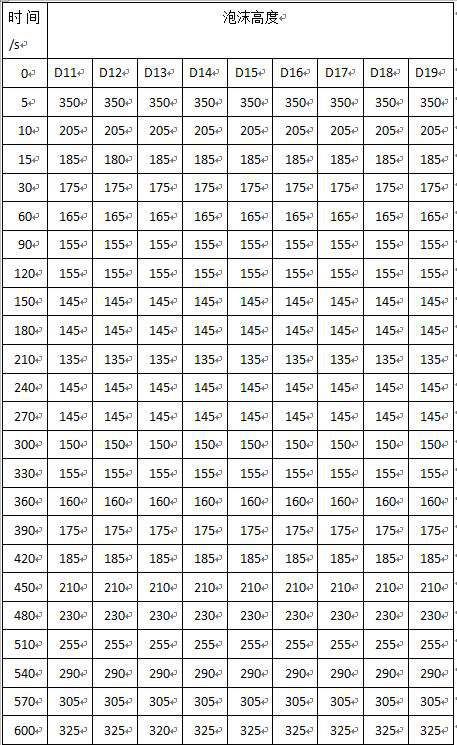

Image

Examples

Embodiment 1

[0036] 1) Mix 40g of hydroxyethyl acrylate, 4g of α-dodecene, 4g of allyl methacrylate and 0.2g of benzoyl peroxide with ordinary stirring method to obtain the mixture H1;

[0037] 2) Add 47.6g of fatty alcohol polyoxyethylene ether, 4g of granular polyisobutylene and 0.2g of benzoyl peroxide into the reaction kettle, stir evenly with ordinary stirring, raise the temperature to 60°C, and then add dropwise under stirring Mixture H1, control the dropping time at 3h; ensure the temperature is controlled at 60°C by circulating water during the dropping;

[0038] 3) After the dropwise addition reaction, the heat preservation reaction was continued for 0.5 h to obtain the defoamer composition D1.

Embodiment 2

[0040] 1) Mix 50g of n-butyl acrylate, 2g of α-methylstyrene, 2g of double-terminated vinyl-terminated polysiloxane and 0.4g of benzoyl peroxide uniformly by high-speed dispersion to obtain mixture H2;

[0041] 2) Add 40g of polypropylene glycol 200, 5.2g of granular polymethacrylic resin and 0.4g of benzoyl peroxide into the reaction kettle and stir evenly in a high-speed dispersion manner, raise the temperature to 100°C, and then add dropwise under stirring For the mixture H2, the dropping time is controlled at 8 hours; during the dropping, the temperature is controlled at 100°C by means of cooling water;

[0042] 3) After the dropwise addition reaction, the heat preservation reaction was continued for 2 hours to obtain the defoamer composition D2.

Embodiment 3

[0044] 1) Mix 40g of isooctyl methacrylate, 2.4g of α-octadecene, 3.0g of vinyl MQ silicone resin and 0.3g of benzoyl peroxide with magnetic stirring to obtain mixture H3;

[0045] 2) Add 50g of polypropylene glycol 600, 4g of white carbon black and 0.3g of benzoyl peroxide into the reaction kettle and stir evenly with magnetic stirring, raise the temperature to 80°C, then add the mixture H3 dropwise under stirring, control The dropping time is 6 hours; during the dropping, the temperature is controlled at 80°C by means of cooling water;

[0046] 3) After the dropwise addition reaction, the heat preservation reaction was continued for 1 hour to obtain the defoamer composition D3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com