Antimony-based tailing adsorbing material, preparation method and applications thereof

An adsorption material, antimony tailings technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of complex production process, cumbersome preparation process, secondary pollution, etc., and improve the pore structure. , the preparation method is simple, the effect of strong adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

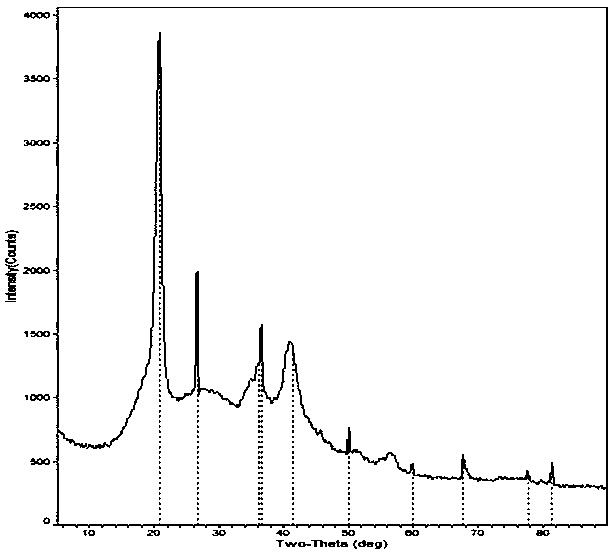

Image

Examples

Embodiment 1

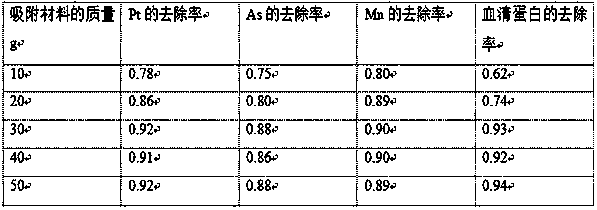

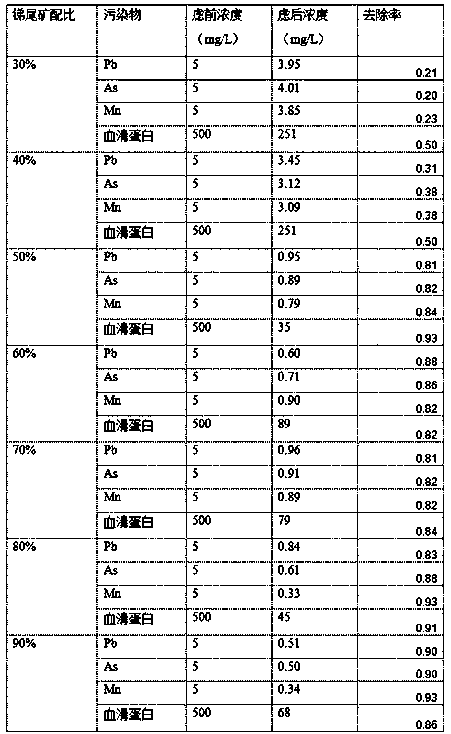

[0028] Example 1: Antimony tailings adsorption materials prepared with different ratios of antimony tailings and viscous agents (commercially purchased ultrafine kaolin) are effective against heavy metals Pt, As, Mn and high-concentration organic emulsified wastewater (serum protein simulates high-concentration organic emulsified wastewater) Adsorption detection of

[0029] 1. The preparation process of antimony tailings adsorption material is as follows:

[0030] (1) Wash the antimony tailings with water until the pH of the washing solution is 6.5, dry and pulverize them, and then take the following percentages of powdered antimony tailings: 30%, 40%, 50%, 60%, 70%, 80%, 90% % and kaolin 70%, 60%, 50%, 40%, 30%, 20%, 10%, mix evenly;

[0031] (2) Add deionized water, stir until viscous, use a particle forming mold to form the viscous mixture into balls, and make 1 part for each ratio;

[0032] (3) Each portion is fired at 1000°C for 12 hours;

[0033] (4) After taking out ...

Embodiment 2

[0038] Embodiment 2: 90% of antimony tailings and 10% of ultra-fine kaolin; the antimony tailings adsorption material fired for 12h under different firing temperatures is effective for metal Pt, As, Mn and high-concentration organic emulsified wastewater (serum protein simulates high Concentration organic emulsified wastewater) adsorption performance test, the content is as follows

[0039] (1) Wash the antimony tailings with water until the pH of the washing solution is 7, dry and pulverize, take the antimony tailings powder and superfine kaolin and mix them thoroughly;

[0040] (2) Add deionized water, stir until viscous, use a particle forming mold to form the viscous mixture into a ball, and make a total of 9 parts;

[0041](3) The firing temperatures are 400°C, 500°C, 600°C, 700°C, 800°C, 900°C, 1000°C, 1100°C, 1200°C, and calcined for 12 hours;

[0042] (4) Take it out and cool it, wash it with deionized water for 3-5 times, dry it, and then fire it into antimony tailin...

Embodiment 3

[0048] Example 3: 90% of antimony tailings and 10% of ultra-fine kaolin; the antimony tailings adsorption material fired for different times at a firing temperature of 1000°C is effective for metal Pt, As, Mn and high-concentration organic emulsified wastewater (serum Protein simulates the adsorption performance of high-concentration organic emulsified wastewater), the content is as follows:

[0049] (1) Wash the antimony tailings with water until the pH of the washing solution is 7, dry and pulverize, take the antimony tailings powder and superfine kaolin and mix them thoroughly;

[0050] (2) Add deionized water, stir until viscous, use a particle forming mold to form the viscous mixture into a ball, and make a total of 9 parts;

[0051] (3) Fire at 1000°C for 8h, 10h, 12h, 14h, 16h, 18h, 20h, 22h, 24h;

[0052] (4) Take it out and cool it, wash it with deionized water for 5 times, dry it, and then fire it into antimony tailings adsorption materials with different firing tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com