A kind of adsorption material based on antimony tailings and its preparation method and application

A technology of adsorption materials and antimony tailings, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of cumbersome preparation process, complicated production process, secondary pollution, etc., and achieve the goal of firing process Simplicity, increase economic value, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

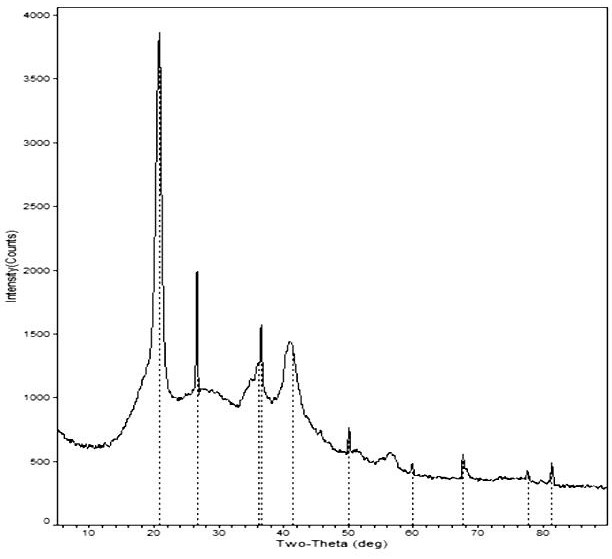

Image

Examples

Embodiment 1

[0028] Example 1: Antimony tailings adsorption materials prepared with different ratios of antimony tailings and viscous agents (commercially purchased ultrafine kaolin) are effective against heavy metals Pt, As, Mn and high-concentration organic emulsified wastewater (serum protein simulates high-concentration organic emulsified wastewater) Adsorption detection of

[0029] 1. The preparation process of antimony tailings adsorption material is as follows:

[0030] (1) Wash the antimony tailings with water until the pH of the washing solution is 6.5, dry and pulverize them, and then take the following percentages of powdered antimony tailings: 30%, 40%, 50%, 60%, 70%, 80%, 90% % and kaolin 70%, 60%, 50%, 40%, 30%, 20%, 10%, mix evenly;

[0031] (2) Add deionized water, stir until viscous, use a particle forming mold to form the viscous mixture into balls, and make 1 part for each ratio;

[0032] (3) Each portion is fired at 1000°C for 12 hours;

[0033] (4) After taking out ...

Embodiment 2

[0038] Embodiment 2: 90% of antimony tailings and 10% of ultra-fine kaolin; the antimony tailings adsorption material fired for 12h under different firing temperatures is effective for metal Pt, As, Mn and high-concentration organic emulsified wastewater (serum protein simulates high Concentration organic emulsified wastewater) adsorption performance test, the content is as follows

[0039] (1) Wash the antimony tailings with water until the pH of the washing solution is 7, dry and pulverize, take the antimony tailings powder and superfine kaolin and mix them thoroughly;

[0040] (2) Add deionized water, stir until viscous, use a particle forming mold to form the viscous mixture into a ball, and make a total of 9 parts;

[0041](3) The firing temperatures are 400°C, 500°C, 600°C, 700°C, 800°C, 900°C, 1000°C, 1100°C, 1200°C, and calcined for 12 hours;

[0042] (4) Take it out and cool it, wash it with deionized water for 3-5 times, dry it, and then fire it into antimony tailin...

Embodiment 3

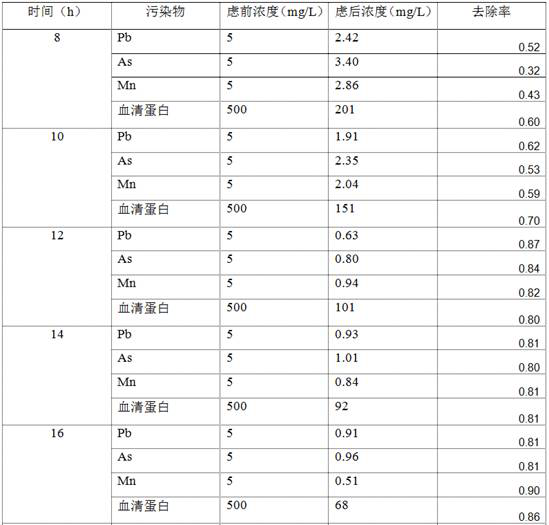

[0048] Example 3: 90% of antimony tailings and 10% of ultra-fine kaolin; the antimony tailings adsorption material fired for different times at a firing temperature of 1000°C is effective for metal Pt, As, Mn and high-concentration organic emulsified wastewater (serum Protein simulates the adsorption performance of high-concentration organic emulsified wastewater), the content is as follows:

[0049] (1) Wash the antimony tailings with water until the pH of the washing solution is 7, dry and pulverize, take the antimony tailings powder and superfine kaolin and mix them thoroughly;

[0050] (2) Add deionized water, stir until viscous, use a particle forming mold to form the viscous mixture into a ball, and make a total of 9 parts;

[0051] (3) Fire at 1000°C for 8h, 10h, 12h, 14h, 16h, 18h, 20h, 22h, 24h;

[0052] (4) Take it out and cool it, wash it with deionized water for 5 times, dry it, and then fire it into antimony tailings adsorption materials with different firing tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com