Oil-contaminated soil remediation agent and preparation thereof

A soil remediation agent and oil pollution technology, applied in the field of soil remediation, can solve the problems of environmental and beach damage, secondary pollution of the environment, etc., and achieve the effect of improving adsorption capacity and enriching pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

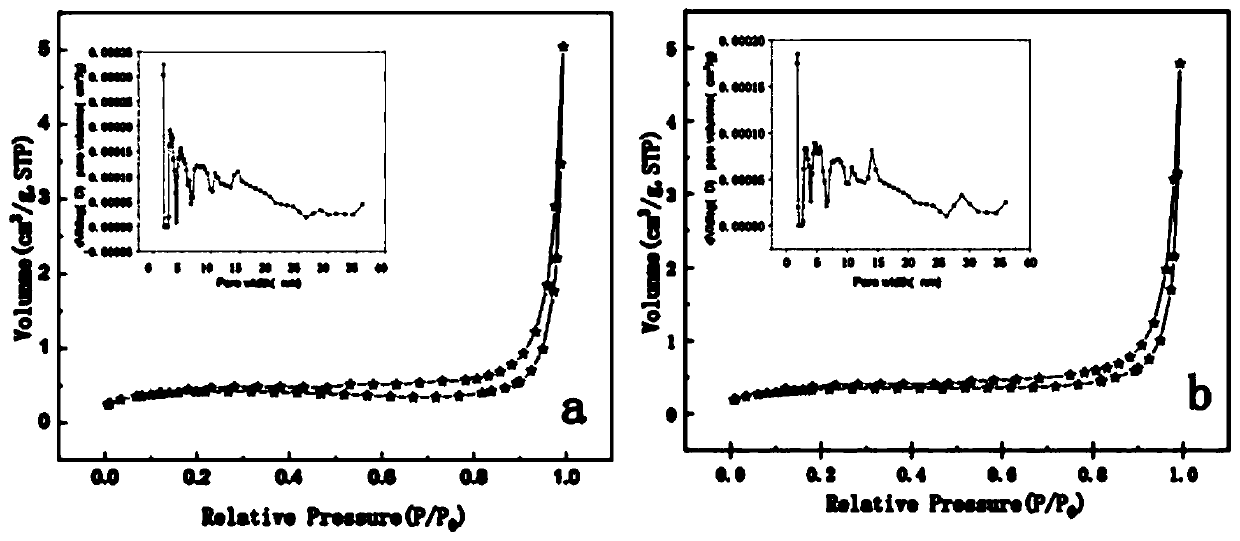

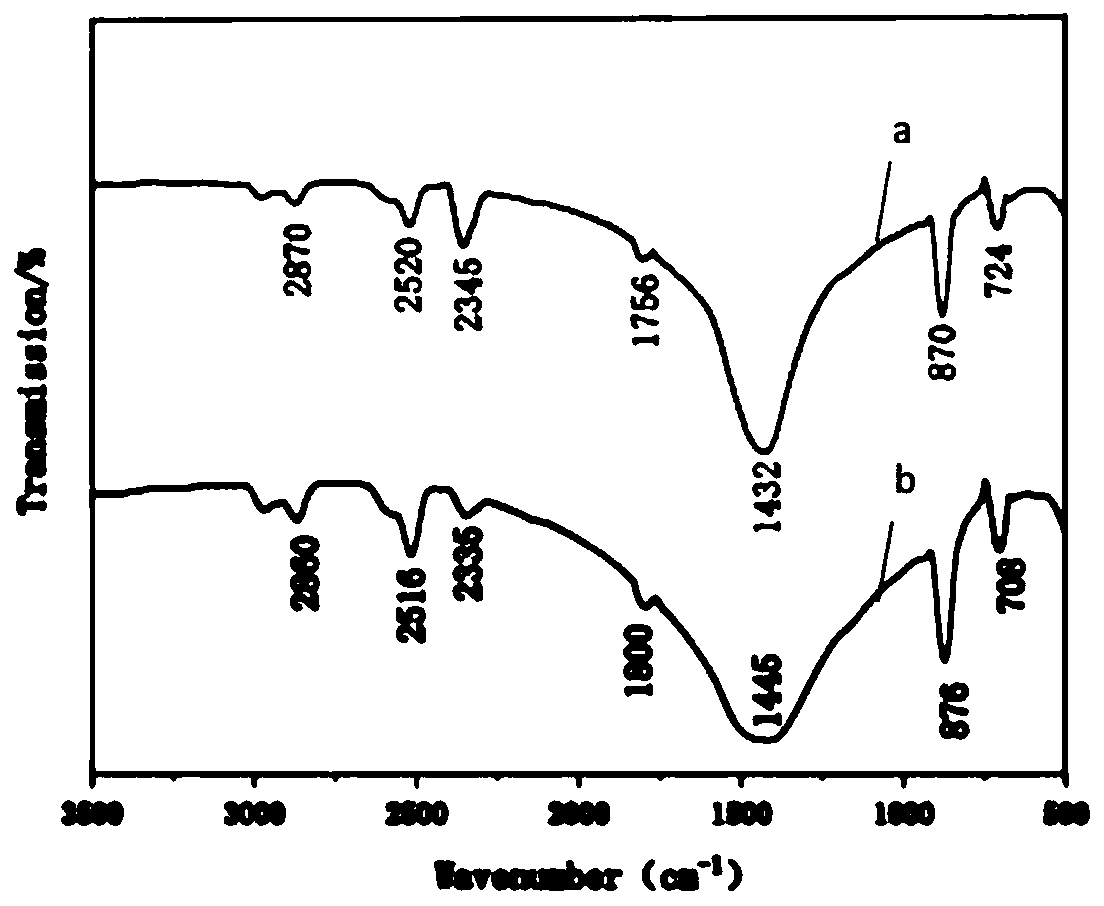

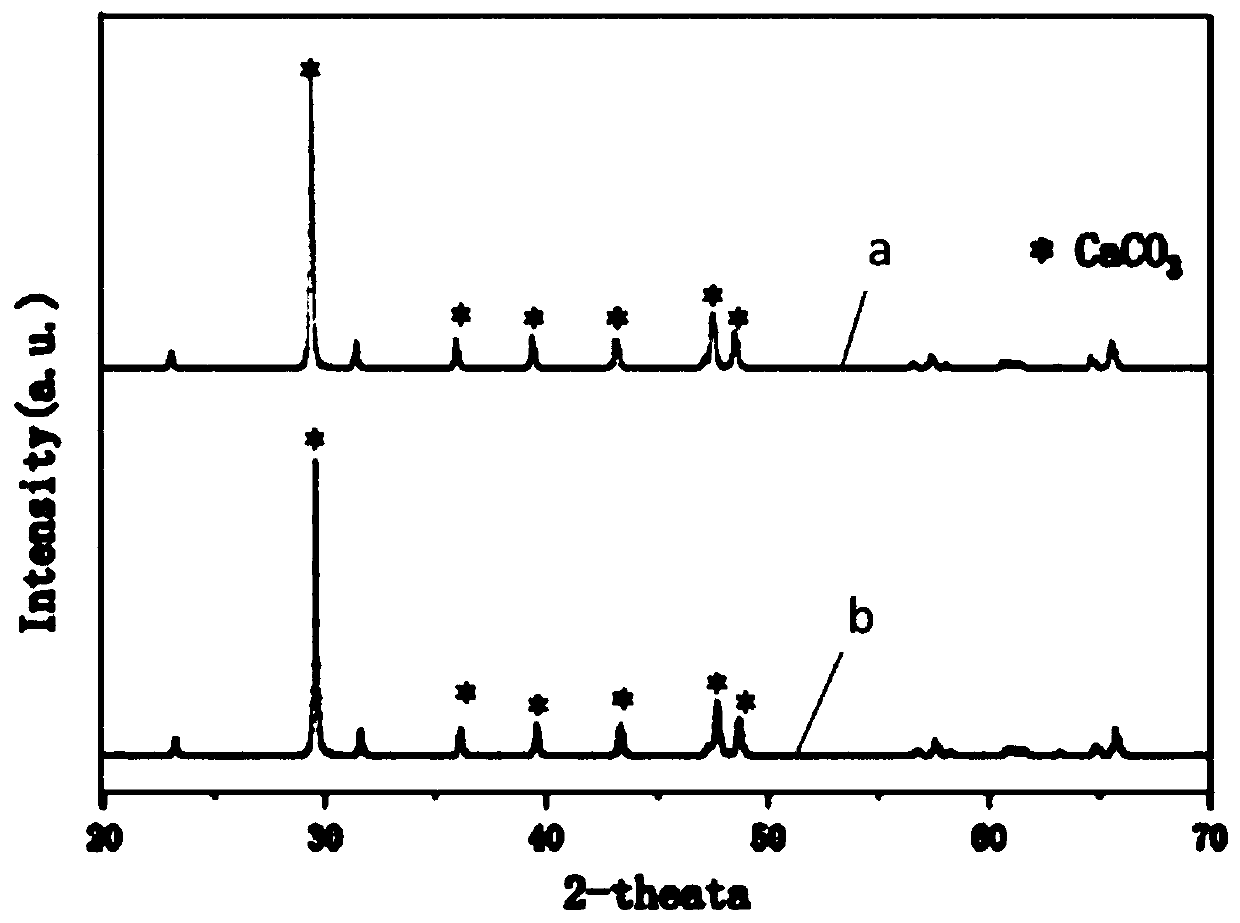

[0049] The preparation of embodiment 1 oily soil remediation agent

[0050] A preparation method of oily soil remediation agent, it may further comprise the steps:

[0051] 1) shell pretreatment

[0052] Soak 500g of blue mussel shells in 50L of 1% HCl solution for 24 hours to remove impurities, rinse with distilled water to remove residual hydrochloric acid on the surface, and then dry them in an oven at 60°C for 24 hours to obtain 400.8g of pretreated blue mussel shells;

[0053] 2) Surfactant freeze penetration

[0054] Soak the blue mussel shells pretreated in step 1) in 20L 0.5% fatty alcohol polyoxyethylene ether (AEO-9) surfactant for 48h, freeze at -20°C for 24h, and then place them in an oven at 80°C Medium drying for 24h;

[0055] 3) high temperature calcination

[0056] Grind the frozen shells in step 2) into powder with a particle size of 50 mesh for subsequent high-temperature calcination, place it in a muffle furnace, and raise the temperature to 300°C at a r...

Embodiment 2

[0058] The preparation of embodiment 2 oily soil remediation agent

[0059] A preparation method of oily soil remediation agent, it may further comprise the steps:

[0060] 1) shell pretreatment

[0061] Soak 100g of blue mussel shells in 10L of 1% HCl solution for 24 hours to remove impurities, rinse with distilled water to remove residual hydrochloric acid on the surface, and then dry them in an oven at 60°C for 24 hours to obtain 82g of pretreated blue mussel shells;

[0062] 2) Surfactant freeze penetration

[0063] Soak the blue mussel shells pretreated in step 1) in 4L 0.5% fatty alcohol polyoxyethylene ether (AEO-9) surfactant for 48h, freeze at -20°C for 24h, and then place them in an oven at 80°C Medium drying for 24h;

[0064] 3) high temperature calcination

[0065] Grind the frozen shells in step 2) into powder with a particle size of 50 mesh for subsequent high-temperature calcination, place it in a muffle furnace, and raise the temperature to 300°C at a rate ...

Embodiment 3

[0067] The preparation of embodiment 3 oily soil remediation agent

[0068] A preparation method of oily soil remediation agent, it may further comprise the steps:

[0069] 1) shell pretreatment

[0070] Soak 150g of blue mussel shells in 15L of 1% HCl solution for 24 hours to remove impurities, rinse with distilled water to remove residual hydrochloric acid on the surface, and then dry them in an oven at 60°C for 24 hours to obtain 124g of pretreated blue mussel shells;

[0071] 2) Surfactant freeze penetration

[0072] Soak the blue mussel shells pretreated in step 1) in 6L 0.5% fatty alcohol polyoxyethylene ether (AEO-9) surfactant for 48h, freeze at -20°C for 24h, and then place them in an oven at 80°C Medium drying for 24h;

[0073] 3) high temperature calcination

[0074] Grind the frozen shells in step 2) into powder with a particle size of 50 mesh for subsequent high-temperature calcination, place it in a muffle furnace, and raise the temperature to 300°C at a rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com