Automatic feeding and discharging device for pipe cutting machine and working method thereof

An automatic loading and unloading technology, which is applied in applications, home appliances, manufacturing tools, etc., can solve the problems of horizontal direction error of deformed pipes, uncontrollable range of cutting error values, poor compatibility of large and heavy pipes, etc. The effect of improving product quality, reducing product error and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

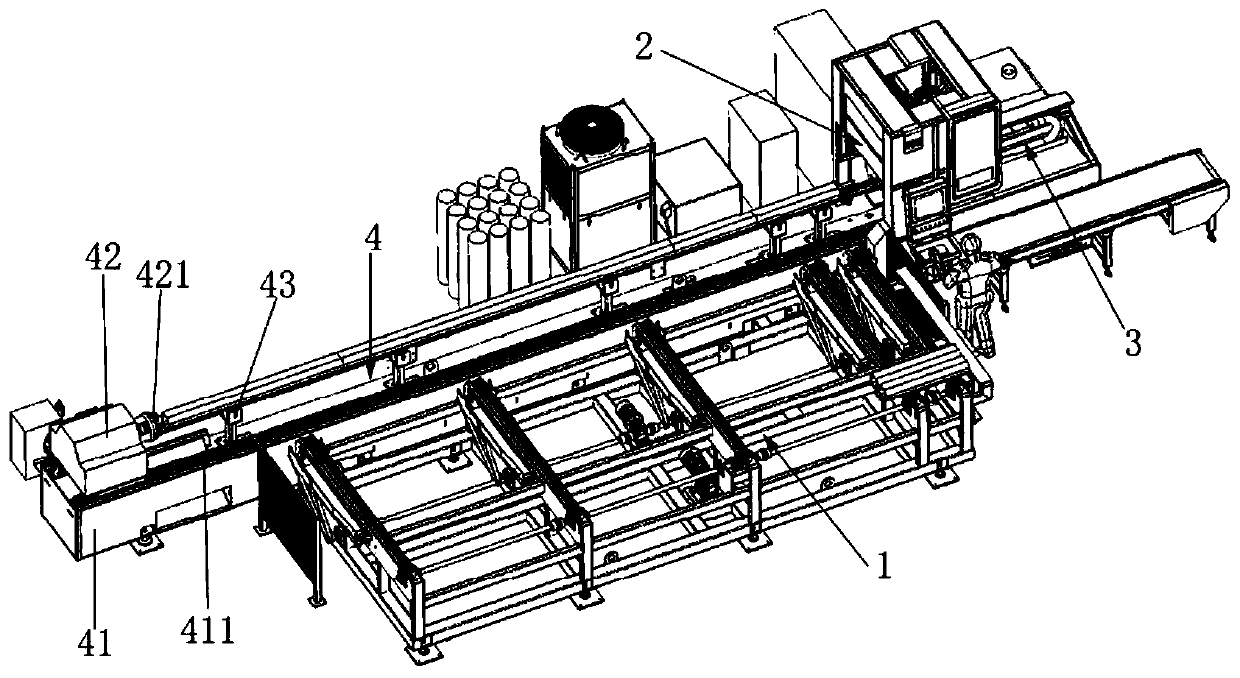

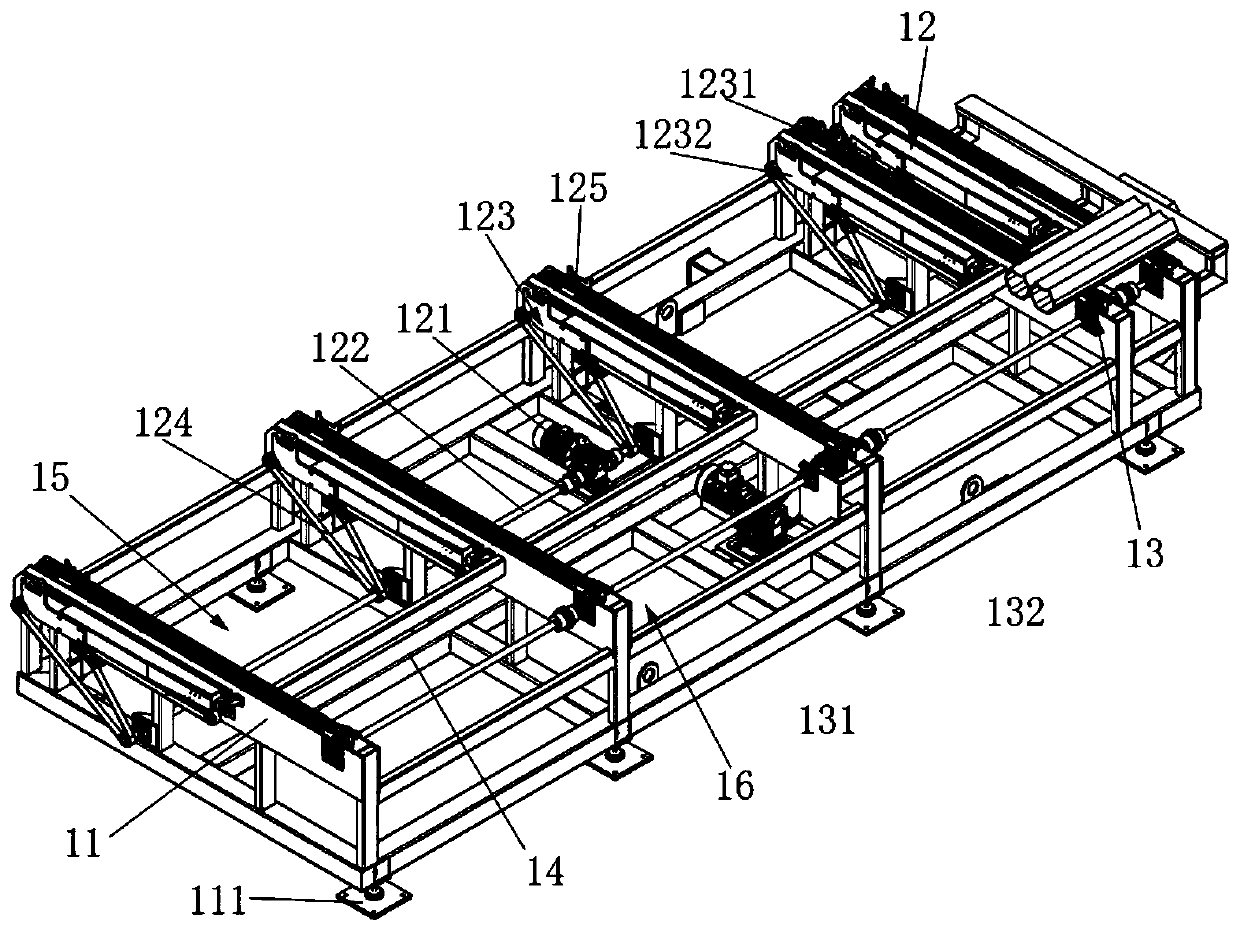

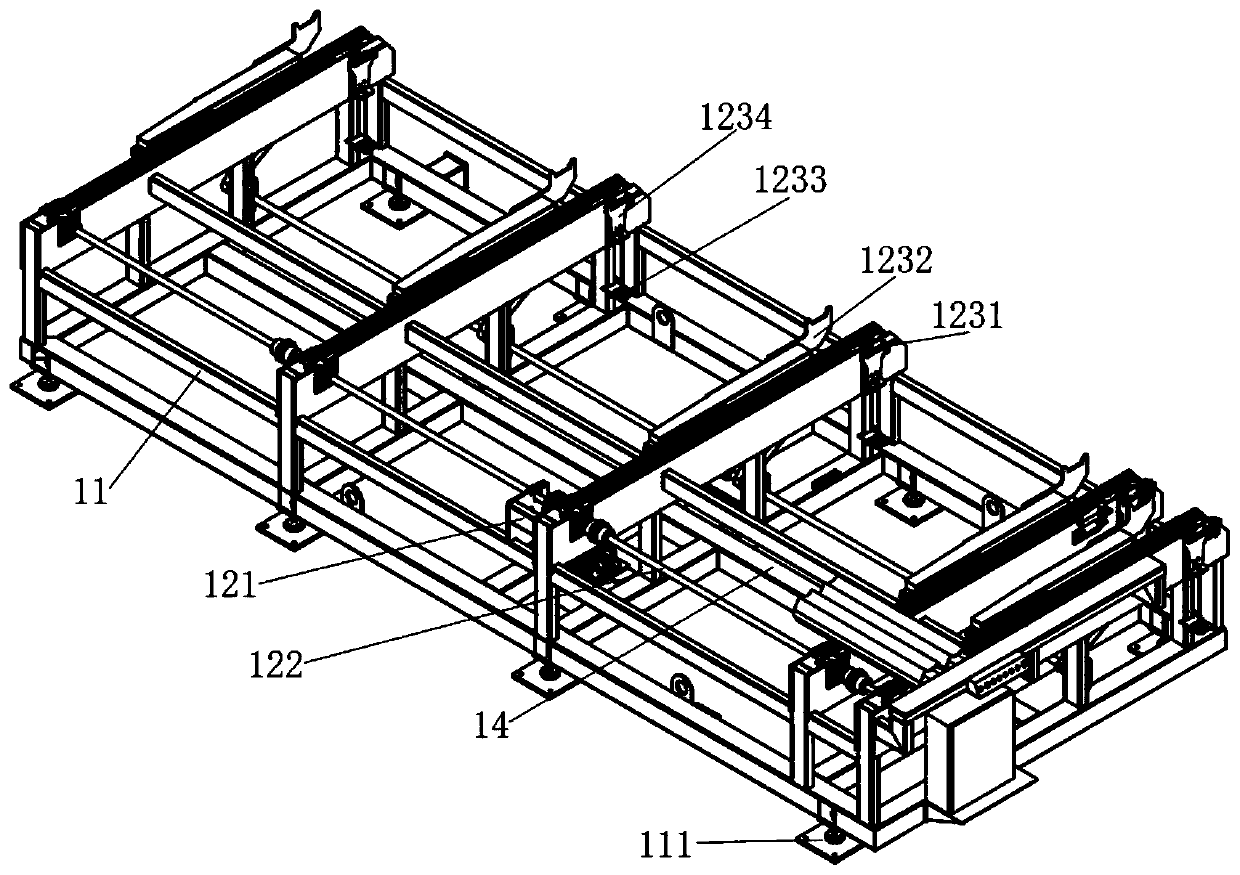

[0034] Such as Figure 1-3 As shown, an automatic loading and unloading device for a pipe cutting machine includes an automatic feeding mechanism 1, a laser pipe cutting machine 2, an automatic blanking device 3 and a workbench 4, and the automatic feeding mechanism 1 is arranged on the workbench 4 side, the laser tube cutting machine 2 is set at the end of the workbench 4, and the automatic blanking device 3 is set at the end of the laser tube cutting machine 2. The automatic feeding mechanism 1 includes a first frame 11, a feeding mechanism 12 and a code material mechanism 13, the bottom of the first frame 11 is provided with a support plate 111, and the first frame 11 is provided with a partition 14. The partition 14 divides the inside of the first frame 11 into two accommodating chambers, the accommodating chambers include a first accommodating chamber 15 and a second accommodating chamber 16, and the first accommodating chamber 15 To be close to the end of the laser pipe...

Embodiment 2

[0039] A working method for an automatic loading and unloading device for a pipe cutting machine, using the automatic loading and unloading device for a pipe cutting machine as described in Embodiment 1 to cut pipes, comprising the following steps:

[0040] (1) Put the pipe to be cut on the buckle 125 of the chain conveyor belt 1231, turn on the second motor 131, the second motor 131 drives the second rotating shaft 132 to rotate, the chain conveyor 1231 is driven by the second rotating shaft 132, and transfers the pipe to On the vertical mechanical transport claw 1234;

[0041] (2) The vertical mechanical delivery claw cylinder 1233 receives the signal, stretches upwards, pushes the pipe to a certain height, the first motor 121 starts after receiving the signal, and the first rotating shaft 122 follows the first motor 121 to rotate, and the first rotating shaft 122 The horizontal mechanical conveying claw 1232 connected by the transmission belt 124 is driven by the first rota...

Embodiment 3

[0046] This embodiment is a modification example of Embodiment 1, on the basis of Embodiment 1, a welding seam identification device 5 is added, such as Figure 5-6 As shown, the welding seam identification device includes a mounting bracket 51 , a connecting part 52 and a rotating part 53 , the connecting part 52 includes a connecting block 521 and a rotating cylinder 522 , and the rotating cylinder 522 is arranged in the connecting block 521 . The rotating part 53 includes a rotating arm 531, the angle between the plane where the rotating arm 531 is located and the plane where the connecting block 521 is located is 45°, one end of the rotating arm 531 is connected with the rotating cylinder 522, and the rotating arm The other end of 531 is provided with a line laser source 533, and a camera 532 is provided near the end of the rotating cylinder 522 on the rotating arm 531. The camera 532 is a GigE area array industrial camera, and the camera 532 and the line laser source 533 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com