Method for cutting silicon wafer in thinning manner

A technology for thinning silicon wafers and cutting silicon wafers. It is applied to fine working devices, grinding machines, and working accessories. It can solve problems such as poor performance of silicon wafers, large vibration amplitude of diamond wires, and uneven thickness of silicon wafers. , to achieve the effect of low surface roughness and damaged layer thickness, short cutting time, and less loss of silicon material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

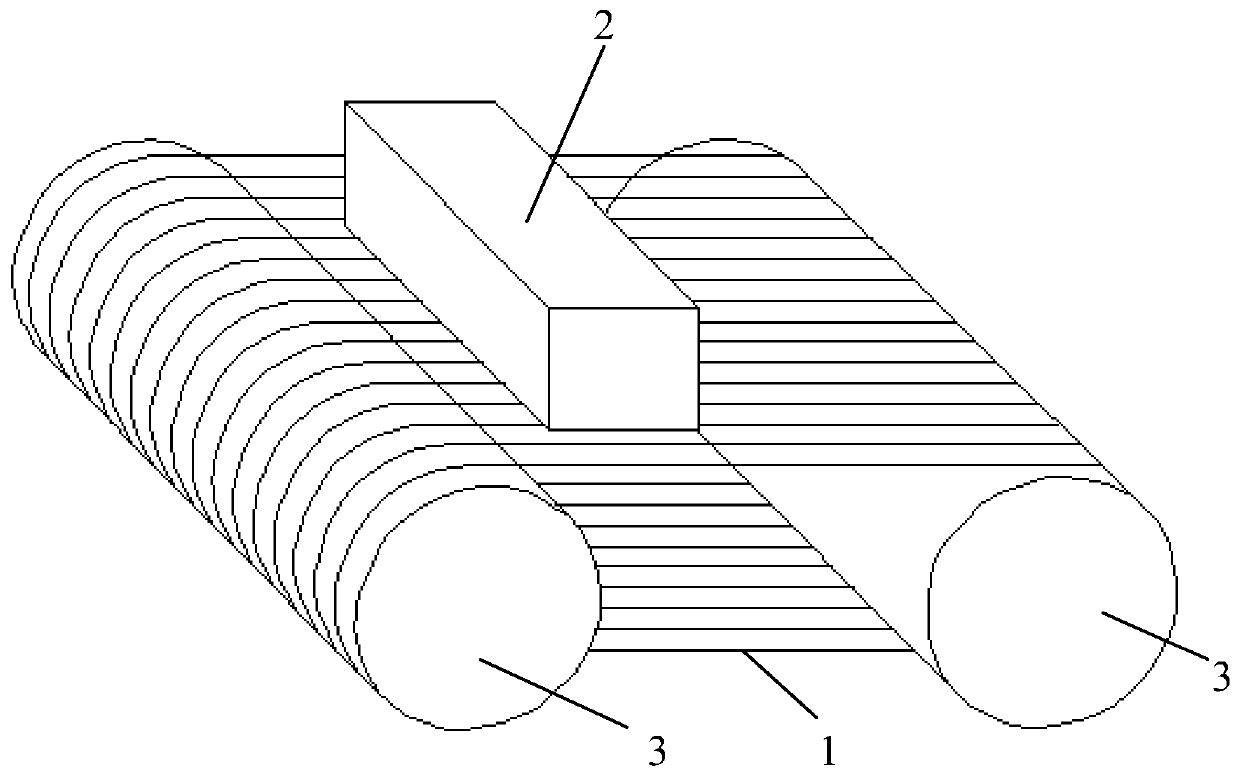

[0018] The present invention will be further explained below in conjunction with the drawings.

[0019] The invention discloses a method for cutting thin wire silicon wafers. The method adopts a diamond wire 1 with a diameter of 45um for cutting, and during the cutting process, the acceleration of the diamond wire 1 is 5m / s 2 -9m / s 2 , The operating speed is 800m / min-2000m / min; the tension of the diamond wire 1 is 6N-13N; the downward movement speed of the silicon material 2 is set as: the cutting area 0.5mm / min -1.5mm / min; the main cutting area 1.6 mm / min-2.8mm / min; cutting area 0.2mm / min-1.0mm / min.

[0020] The acceleration of the diamond wire 1 can be set to 6m / s 2 Or 8m / s 2 .

[0021] The operating speed of the diamond wire 1 can be set to 1000 m / min or 1200 m / min or 1500 m / min or 1800 m / min.

[0022] The tension of the diamond wire 1 can be set to 8N or 10N.

[0023] During the cutting process, the grooved wheel 3 reciprocates to drive the diamond wire 1 into a saw-like reciprocat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com