Dustproof and oxygen-permeable deoxidizer packaging material and production process thereof

A production process and deoxidizer technology, which is applied in the field of dust-proof oxygen-permeable deoxidizer packaging materials and their production processes, can solve the problems of poor air permeability of packaging materials, achieve good elasticity, increase viscosity, and good dust-proof effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

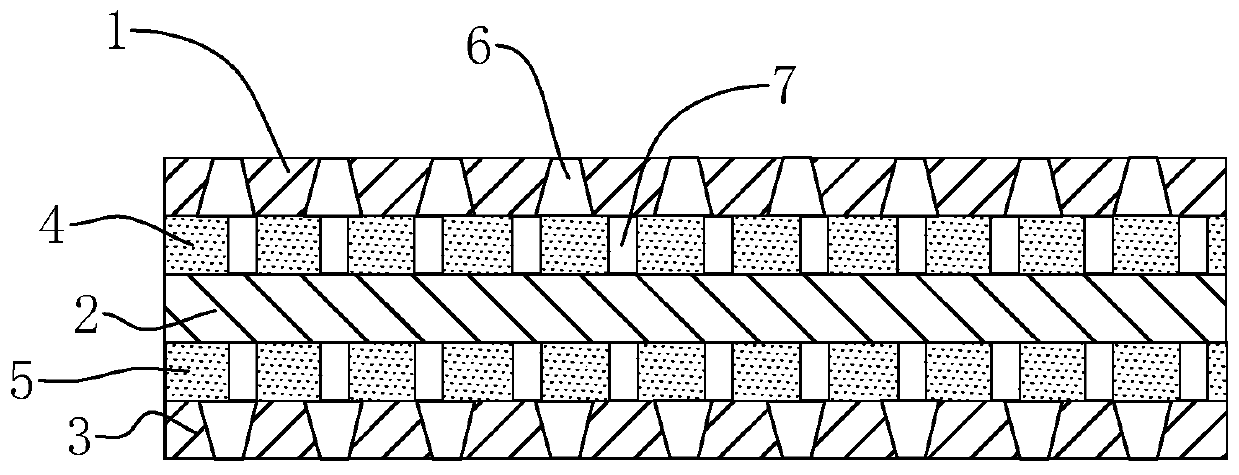

[0059] Embodiment 1: A kind of packaging material of dust-proof oxygen-permeable deoxidizer, such as figure 1 As shown, it includes a polyethylene co-extrusion layer 1, a first adhesive layer 4, a dustproof paper layer 2, a second adhesive layer 5, and a dustproof paper layer 3. Usually, the dustproof paper layer 3 is the outer layer, and the polyethylene co-extrusion layer Extruded layer 1 is the inner layer. Apply glue on both surfaces of the dust-proof paper layer 2 (the glue is composed of Dow water-based glue L-168, Dow curing agent CR3A, and carboxymethyl cellulose with a weight ratio of 100:2:1) .

[0060] Wherein, the polyethylene co-extruded layer 1 and the dust-proof paper layer 3 are provided with vent holes 6, and the aperture of the vent holes 6 is 0.3 mm, and the vent holes 6 are formed on the polyethylene co-extruded layer 1 and the dust-proof paper layer 3. The hole spacing is 1 mm.

[0061] Wherein, the thickness of polyethylene co-extruded layer 1 and dust...

Embodiment 2-6

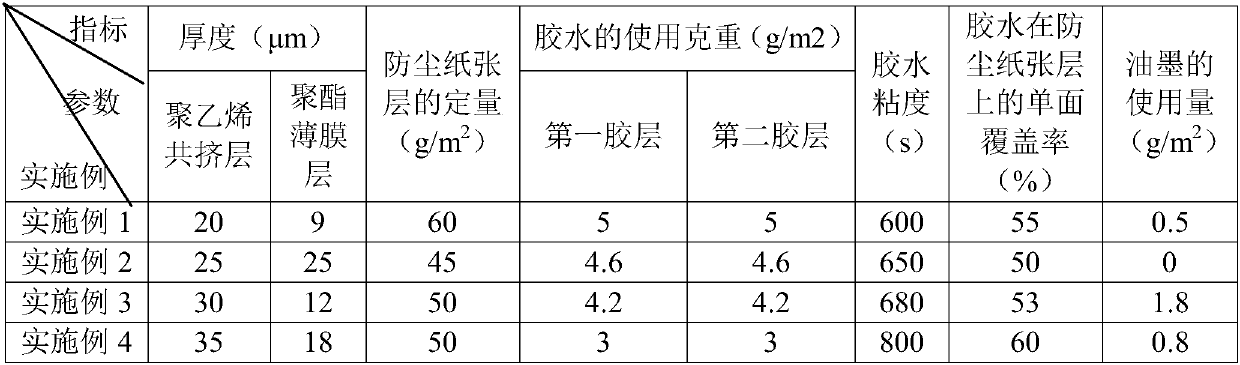

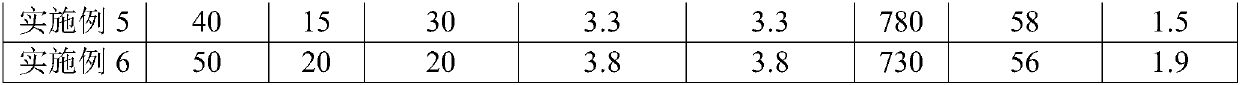

[0079] Embodiment 2-6: A dust-proof, oxygen-permeable and deoxidizer packaging material, the difference from Example 1 is the thickness of the polyethylene co-extrusion layer 1 and the dust-proof paper layer 3, the quantification of the dust-proof paper layer 2, and the second The coverage of the first glue layer 4 and the second glue layer 5 on the dust-proof paper layer 2 and the usage amount of glue therein, the usage amount of the ink are as shown in Table 1, and the polyethylene co-extrusion layer 1 in embodiment 1-3 The consumption of each raw material in outer layer, middle layer, inner layer is as shown in table 2, and the usage amount of each raw material in outer layer, middle layer, inner layer in the polyethylene coextruded layer 1 in embodiment 4-6 As in Example 1; the amount of softwood pulp, hardwood pulp, and processing aids contained in the dustproof paper layer 2 is shown in Table 3.

Embodiment 7

[0080] Embodiment 7: A dust-proof, oxygen-permeable and deoxidizer packaging material. The difference from Embodiment 1 is that the holes in the polyethylene co-extrusion layer 1 gradually expand in the shape of a cone from the outer layer to the inner layer, and the largest hole diameter on the outer layer is is 0.25mm, and the largest hole diameter on the inner layer is 0.4mm. The vent hole 6 on the dustproof paper layer 3 is gradually reduced from the side close to the dustproof paper layer 2 to the side away from the dustproof paper layer 2, and the largest The hole diameter is 0.3mm, and the smallest hole diameter is 0.4mm; and the hole spacing of the ventilation holes 6 on the polyethylene co-extrusion layer 1 and the dustproof paper layer 3 is 3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com