Central drive smart self-adaptive electric drive system

An electric drive system and central drive technology, applied in bicycles, motor vehicles, power units, etc., can solve the problems of difficult production, difficult to guarantee machining accuracy, large motor volume, etc., to increase the range of efficient operation and improve mechanical efficiency. , the effect of improving the cruising range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

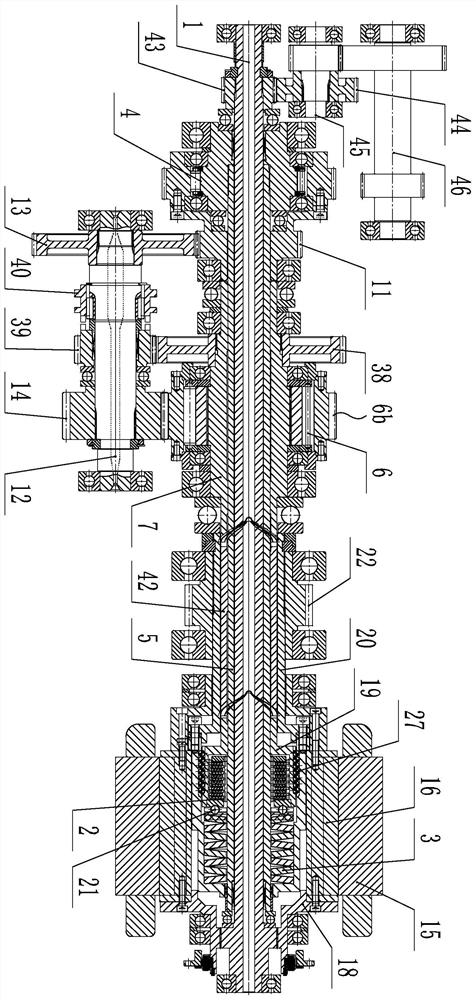

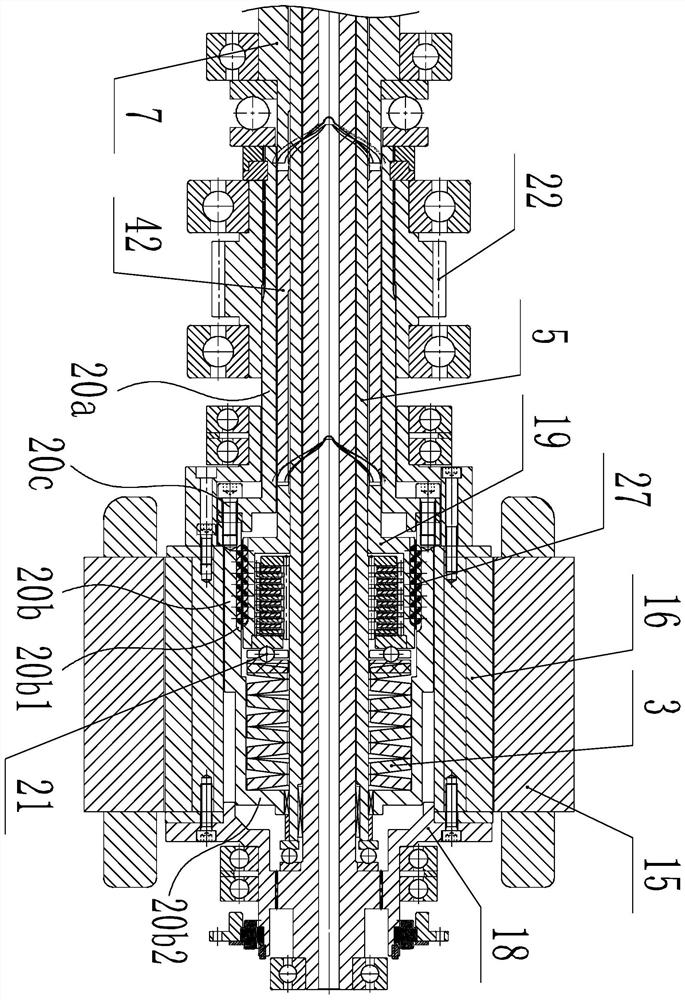

[0041] like Figure 1-Figure 4 As shown, a centrally driven intelligent self-adaptive electric drive system includes a motor, a high-speed transmission mechanism, a low-speed transmission mechanism and a central output mechanism.

[0042] The motor includes a stator 15, a rotor 16 and a motor shaft output assembly driven by the rotor 16. The motor shaft output assembly includes a power transmission flange 18, a motor shaft 1, a first reduction assembly and a first overrunning clutch 4, The rotor 16 can transmit power to the motor shaft 1 through the power transmission flange 18 , the first overrunning clutch 4 is rotatably sleeved on the motor shaft 1 , and the motor shaft 1 can transmit power to the motor shaft 1 .

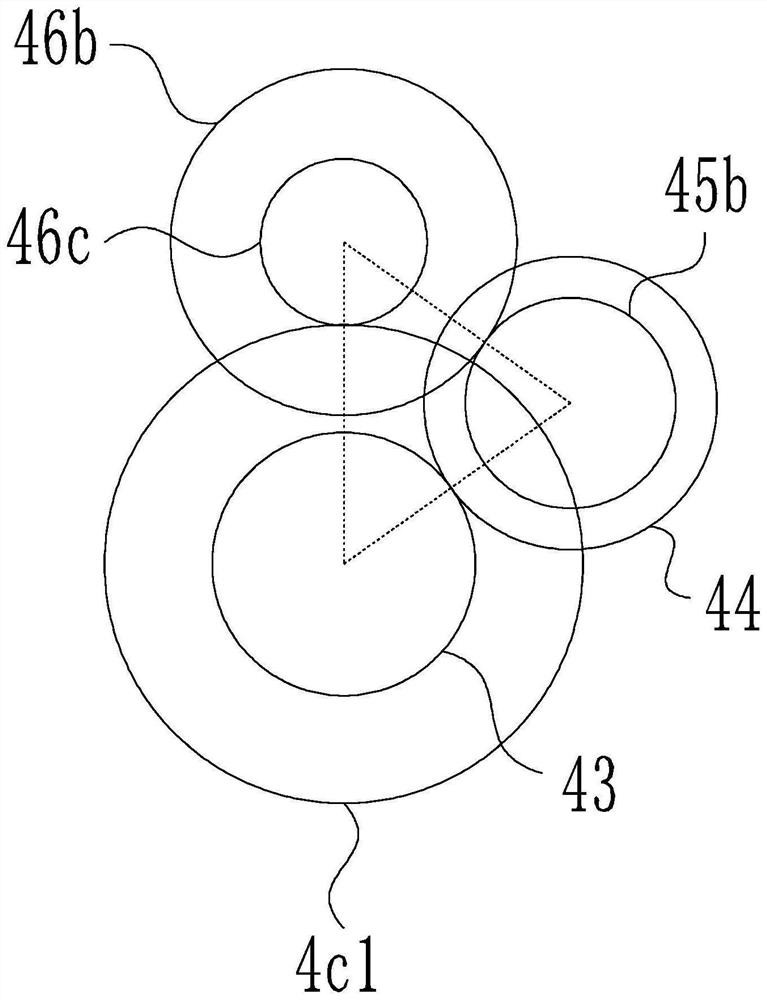

[0043] See figure 1 , figure 2 and Figure 4 , the first deceleration assembly includes a first-stage deceleration driving gear 43, a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com