Graphene waterborne polyurethane based sponge modification method

A polyurethane sponge, alkene water-based technology, applied in coatings and other directions, can solve the problems of insensitivity, inability to maintain high sensitivity and wide measurement range at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

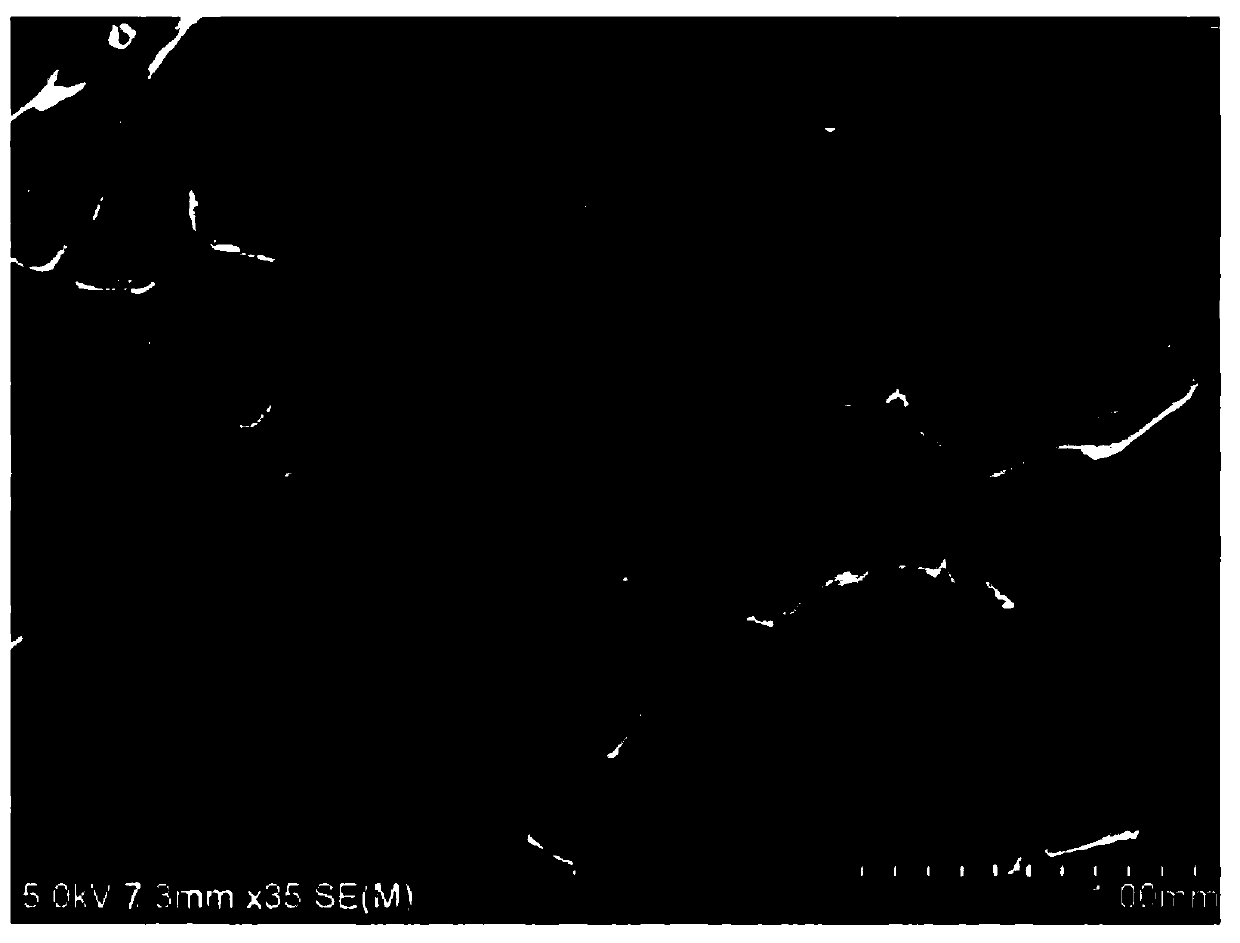

Image

Examples

Embodiment 1

[0029] (1) Graphene oxide 15g prepared by the Hummers method is mixed with deionized water 1500g and ultrasonically dispersed fully to obtain a graphene oxide dispersion,

[0030] Add 70g of polyetheramine D-230 to the above graphene oxide dispersion and stir (stirring speed is 100 rpm) to fully disperse, then raise the temperature to 60°C (oil bath heating) and react for 20 Hour,

[0031] Filter and wash until the filtered cleaning solution is neutral (pH is 7), and the filter cake obtained by filtering is redispersed in 1800g deionized water to obtain a dispersion of modified graphene oxide;

[0032] (2) Add 2.2 g of dibutyltin dilaurate to 457 g of isophorone diisocyanate IPDI, and dropwise add 616 g of polyethylene glycol 400 therein, drop it in 4 hours, and heat up under stirring at 280 rpm After reacting at 50°C (oil bath heating) for 1 hour, add 36g of 1,2-dihydroxy-3-propanesulfonate sodium to it, and keep the aforementioned stirring state and 50°C (oil bath heating) ...

Embodiment 2

[0039] (1) with the step (1) of embodiment 1;

[0040] (2) Add 2.4 g of dibutyltin dilaurate to 346 g of hexamethylene diisocyanate HDI, and dropwise add 965 g of polyethylene glycol 600 therein, drop it in 4.5 hours, and heat up under stirring at 300 rpm After reacting at 50°C (oil bath heating) for 1.5 hours, add 40g of sodium 1,2-dihydroxy-3-propanesulfonate to it, and keep the aforementioned stirring state and 50°C (oil bath heating) to continue the reaction After 5 hours, the resulting reaction system mixture was divided into two on average, each part was 673.4g, and all of them were added dropwise to the dispersion of modified graphene oxide obtained in step (1), and the mixture was dropped in 2 hours. Finished, 700 rev / min stirred and mixed to obtain the water-based polyurethane emulsion grafted with graphene after 2 hours;

[0041](3) Put the cuboid polyurethane sponge block of the same material as in Example 1, which is 6cm long from left to right x 1cm wide from fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com