Preparation method of high-transparency flexible flame-retardant film

A flame-retardant film and transparent technology, which is applied in the field of preparation of highly transparent and flexible flame-retardant films, can solve problems such as the fragility of indium tin oxide films, and achieve excellent flame-retardant properties, small Young's modulus, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

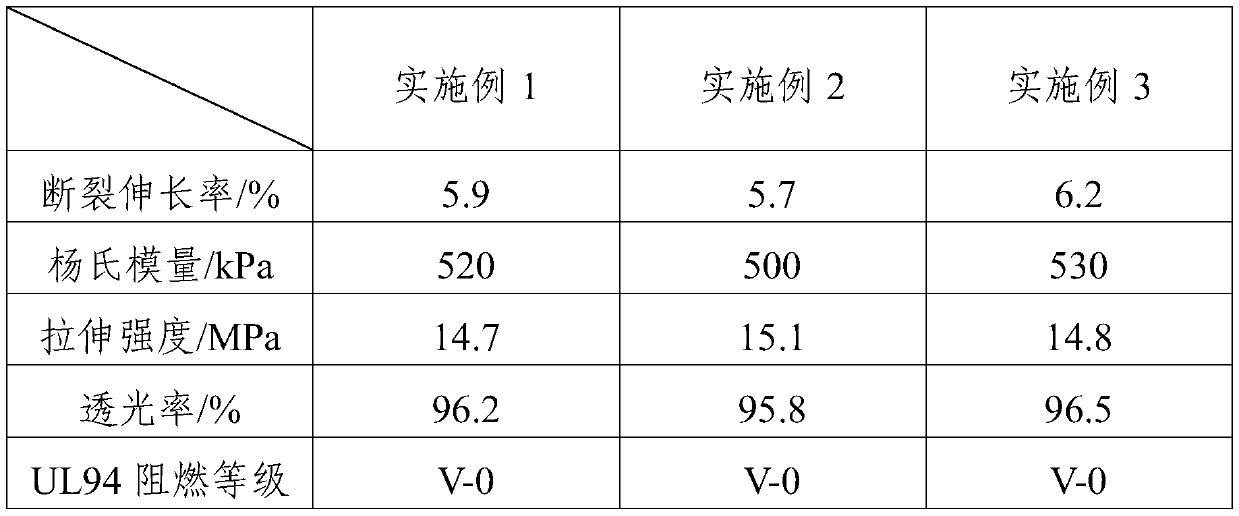

Examples

Embodiment 1

[0028] A preparation method of a highly transparent and flexible flame-retardant film:

[0029] Add hydrazine sulfate, terephthalic acid, and 5-bromoisophthalic acid to oleum, wherein the weight ratio of terephthalic acid and 5-bromoisophthalic acid is 1:0.1, and heat up to 80°C for reaction After 5 hours, raise the temperature to 120°C, continue the reaction for 3 hours, add the terminator benzoic acid, then raise the temperature to 140°C for 2 hours, obtain intermediate A after vacuum defoaming, add cyclic phosphoric anhydride to acetone, heat up to 40°C and stir After making it dissolve, slowly add a certain amount of distilled water. The weight ratio of cyclic phosphoric anhydride to distilled water is 7:1. Mix 1:0.8:0.13, raise the temperature to reflux for 10 hours, filter, and mix the obtained solid with absolute ethanol in a weight ratio of 1:10 at room temperature for 2 hours, filter, and concentrate and dry the filtrate under reduced pressure to obtain intermediate B...

Embodiment 2

[0031] A preparation method of a highly transparent and flexible flame-retardant film:

[0032]Add hydrazine sulfate, terephthalic acid, and 5-bromoisophthalic acid to oleum, wherein the weight ratio of terephthalic acid and 5-bromoisophthalic acid is 1:0.2, and heat up to 90°C for reaction After 5 hours, raise the temperature to 120°C, continue the reaction for 2 hours, add the terminator hydroquinone, then raise the temperature to 140°C for 3 hours, obtain intermediate A after vacuum defoaming, add cyclic phosphoric anhydride to acetone, and heat up to 50 Stir at ℃ to make it dissolve, then slowly add a certain amount of distilled water dropwise, the weight ratio of cyclic phosphoric anhydride to distilled water is 7:1, keep warm for 5 hours after dropping, filter, and dry the product in vacuum with hydroxyethyl acrylate and cationic resin Mix at a weight ratio of 1:0.8:0.13, heat up to reflux for 10 hours, filter, and filter the obtained solid and absolute ethanol at a weig...

Embodiment 3

[0034] A preparation method of a highly transparent and flexible flame-retardant film:

[0035] Add hydrazine sulfate, terephthalic acid, and 5-bromoisophthalic acid to oleum, wherein the weight ratio of terephthalic acid and 5-bromoisophthalic acid is 1:0.2, and heat up to 90°C for reaction After 3-5 hours, raise the temperature to 120°C, continue the reaction for 2 hours, add the terminator hydroquinone, then raise the temperature to 140°C for 3 hours, obtain intermediate A after vacuum defoaming, add cyclic phosphoric anhydride to acetone, and heat up Stir at 50°C to make it dissolve, then slowly add a certain amount of distilled water dropwise, the weight ratio of cyclic phosphoric anhydride to distilled water is 7:1, keep warm for 3 hours after dropping, filter, and dry the product in vacuum with hydroxyethyl acrylate, cationic The resin is mixed at a weight ratio of 1:0.8:0.13, heated to reflux for 10 hours, filtered, and the solid obtained by filtering is mixed with abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com