A kind of preparation method of anti-friction anti-icing coating

A friction-resistant and anti-icing technology, applied in coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve problems such as unsuitable for market requirements, poor mechanical properties of coatings, and complicated preparation methods. Achieve good superhydrophobicity, low preparation cost, and simple experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

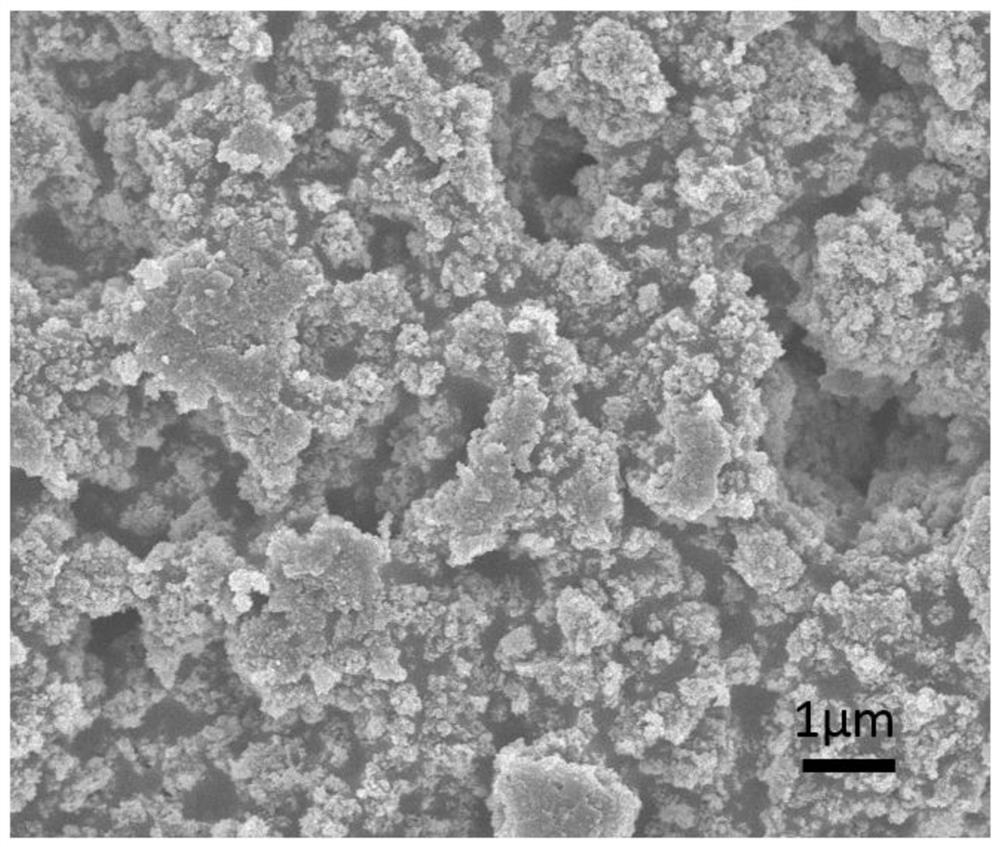

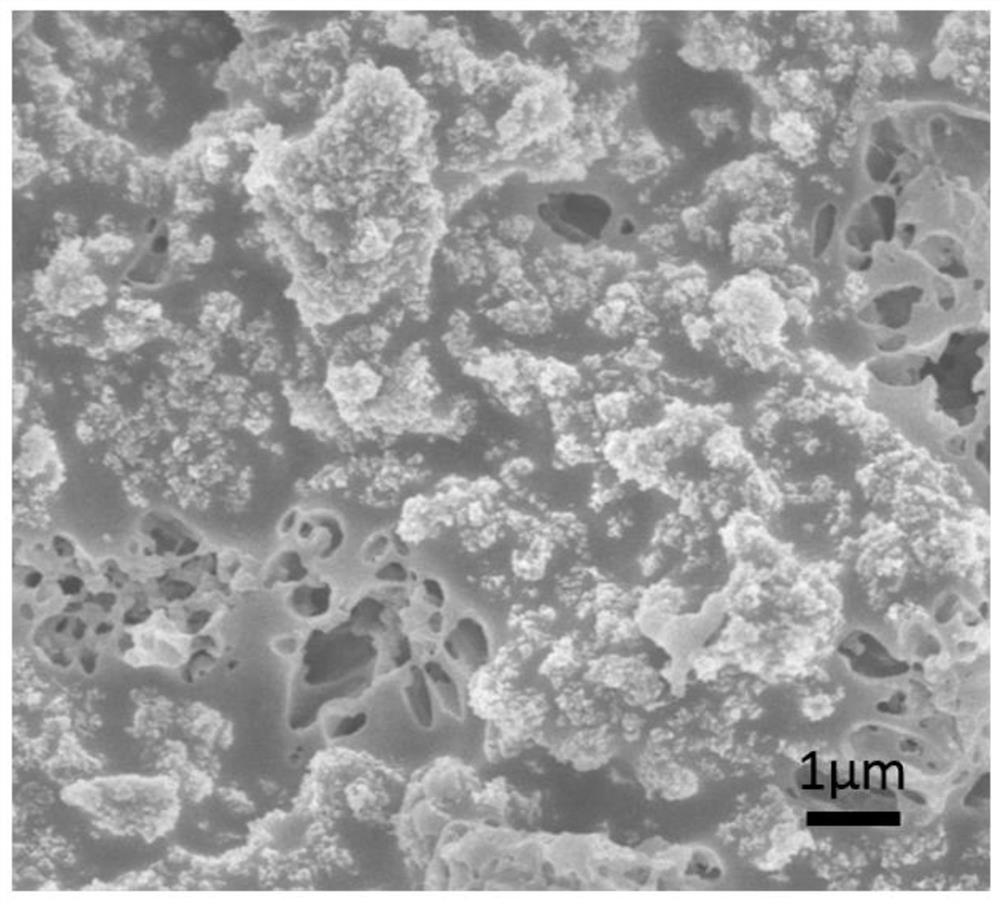

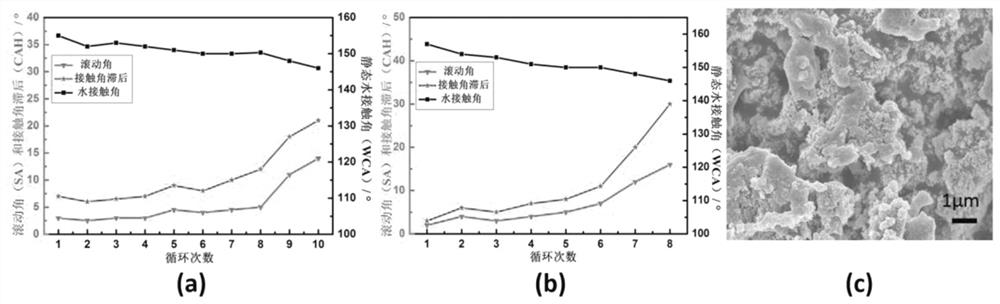

Image

Examples

preparation example Construction

[0023] (1) Preparation of liquid A: Weigh 0.1-0.5g trifluoropropyltrimethoxy, 0.1-1g silica particles (particle diameter 30±5nm) into a small beaker, then add 2-30g ethyl acetate After mixing, stir at room temperature to fully disperse silicon dioxide in ethyl acetate;

[0024] (2) Preparation of liquid B: Weigh 0.06-0.6g of epoxy resin or modified epoxy resin into a weighing bottle, then add 0.5-3g of ethyl acetate for mixing, and add 0.03-0.3g after fully stirring organic amine, stir and dissolve, add 0.1-0.5g of trifluoropropyltrimethoxysilane, and stir at room temperature to fully dissolve;

[0025] (3) Preparation of friction-resistant superhydrophobic coating: Add liquid B dropwise to liquid A under stirring conditions, and then stir at room temperature for 30-100 minutes;

[0026] (4) Preparation of coating: apply the coating in (3) by spraying, brushing or spin coating. Dry the prepared samples at 60-100°C.

[0027] In the step (1), the dosage of trifluoropropyltrim...

Embodiment 1

[0034] In this embodiment, the preparation method of the anti-friction and anti-icing coating, the specific steps are as follows:

[0035] (1) Preparation of liquid A: Weigh 0.1g of trifluoropropyltrimethoxy, 0.1g of silica particles (particle diameter: 30±5nm) into a small beaker, then add 2.5g of ethyl acetate, at room temperature Stir for 10 minutes to fully disperse silicon dioxide in ethyl acetate;

[0036] (2) Preparation of liquid B: Weigh 0.06g of bisphenol A type epoxy resin into a weighing bottle, then add 1g of ethyl acetate to mix, stir well and then add 0.03g of methylcyclopentadiamine, After stirring to dissolve, add 0.1g of trifluoropropyltrimethoxysilane, and stir at room temperature for about 10 minutes to fully dissolve;

[0037] (3) Preparation of friction-resistant superhydrophobic coating: Add liquid B dropwise to liquid A under stirring conditions, and then stir at room temperature for 30 minutes;

[0038] (4) Preparation of the coating: Brush the paint...

Embodiment 2

[0041] In this embodiment, the preparation method of the anti-friction and anti-icing coating, the specific steps are as follows:

[0042](1) Preparation of liquid A: Weigh 0.1g of trifluoropropyltrimethoxysilane and 0.2g of silicon dioxide particles (particle diameter: 30±5nm) into a small beaker, then add 5g of ethyl acetate, at room temperature Under stirring for 20 minutes, silicon dioxide is fully dispersed in ethyl acetate;

[0043] (2) Preparation of liquid B: Weigh 0.3g of acrylic modified epoxy resin into a weighing bottle, then add 2g of ethyl acetate for mixing, stir well, add 0.1g of polyetheramine, stir to dissolve and then add 0.5g of trifluoropropyltrimethoxysilane, stirred at room temperature for about 10 minutes to fully dissolve;

[0044] (3) Preparation of friction-resistant superhydrophobic coating: Add liquid B dropwise to liquid A under stirring conditions, and then stir at room temperature for 20 minutes;

[0045] (4) Coating preparation: Spin-coat the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com