Production process of warp-knitted spandex super-soft polar fleece fabric

A super soft polar fleece, production technology, applied in the direction of warp knitting, layered products, fabric surface trimming, etc., can solve the problem of high fastness of fluff, achieve the effect of not easy to fall off, reduce irritation, and fluff is weak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

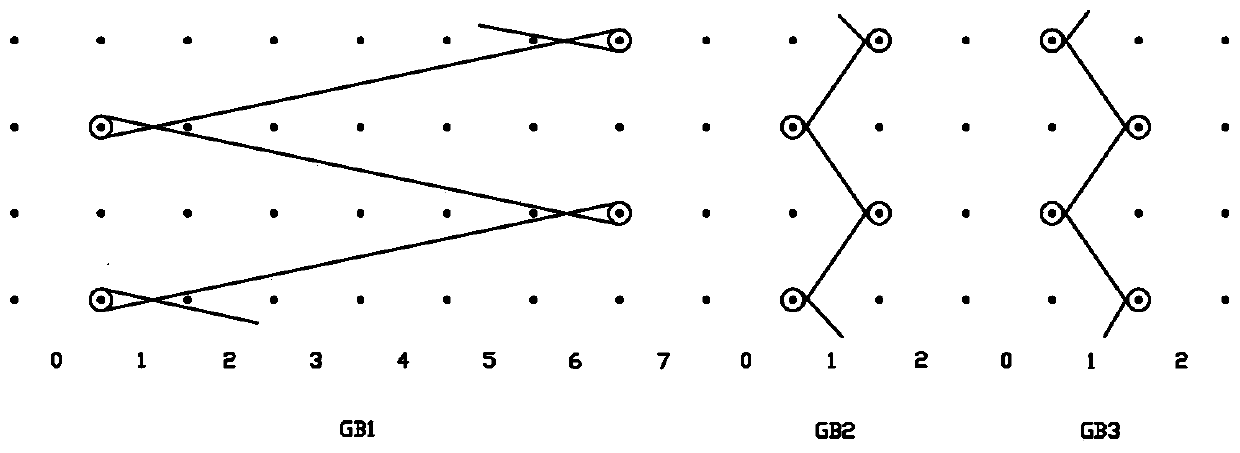

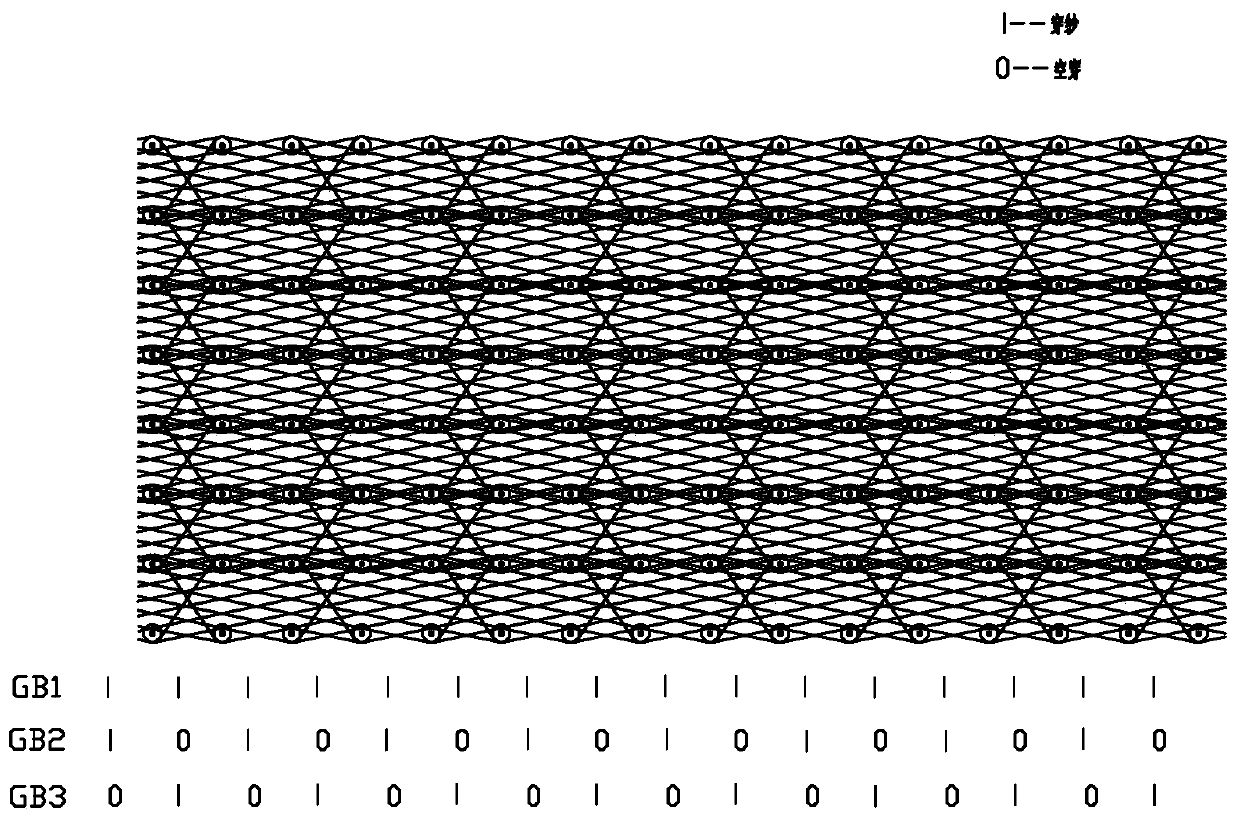

[0039] Reference attached figure 1 and 2 , a production process of warp-knitted spandex supersoft fleece fabric, comprising the following steps:

[0040] (1) Weaving: Warp-knitted spandex super soft polar fleece fabric base fabric is woven by Karl Mayer warp knitting machine. The selected yarn raw materials are 75D144f polyester round hole elastic yarn, 54D24f polyester filament and 40D1F spandex, and are finished by warping machine. After warping, it is machine-woven on a Karl Mayer warp knitting machine;

[0041] Yarns of 3 specifications are warped through 8 pan heads respectively, and each pan head has 650 yarns;

[0042] Warp-knitted spandex ultra-soft polar fleece base fabric is woven with 3 bars GB1, GB2, GB3:

[0043] GB1 feeds 5168 pieces of 75D144f polyester round-hole elastic wire; that is, head pattern 646*8;

[0044] GB2 feeds 5184 pieces of 54D24f polyester filament; that is, head pattern 648*8;

[0045] GB3 is fed with 5184 pieces of 40D1F spandex; that is,...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 is that it also includes steps:

[0063] (11) Glue brushing: Brush the un-raised surface of the warp-knitted spandex super soft polar fleece fabric after step (7) with water-based glue, and the coating amount is 10g / m 2 ;

[0064] (12) Composite: Bond the glued surface of the warp-knitted spandex super soft polar fleece fabric coated with glue in step (9) to the skin-friendly fabric, and roll it up according to step (8).

[0065] Preferable: Skin-friendly fabrics are woven fabrics made of cotton fiber, bamboo fiber, and real silk fiber as yarn raw materials. After compounding skin-friendly fabrics, both sides of the fabric are suitable for close-fitting wear. When the temperature is slightly higher, the skin-friendly layer is close to the body, and the suede can be exposed; when the temperature is slightly lower, the suede is close to the body, which is more warm.

Embodiment 3

[0067] The difference between this embodiment and Embodiment 1 is that it also includes steps:

[0068] (9) Glue brushing: Apply water-based glue to the warp-knitted spandex super soft polar fleece fabric that has been shaped in step (7) and apply water-based glue to the coating amount of 9g / m 2 ;

[0069] (10) Composite: Bond the glue-coated surface of the warp-knitted spandex super soft polar fleece fabric coated with glue in step (9) to the waterproof and breathable membrane, and roll it up according to step (8).

[0070] Preferably: the waterproof and breathable membrane is a polytetrafluoroethylene dispersed resin membrane. The waterproof and breathable raw material is polytetrafluoroethylene dispersion resin, and the polytetrafluoroethylene dispersion resin film is combined with the super soft warp-knitted spandex polar fleece fabric. This fabric can be used as the lining of the outerwear, and the waterproof and breathable membrane can prevent water from penetrating fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com