Glass fiber reinforced PE water supply pipe and preparation method thereof

A water supply pipe and glass fiber technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of high density, sloshing, low strength of glass fiber tape, etc., to improve heat resistance and flame resistance, improve compression performance, Effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

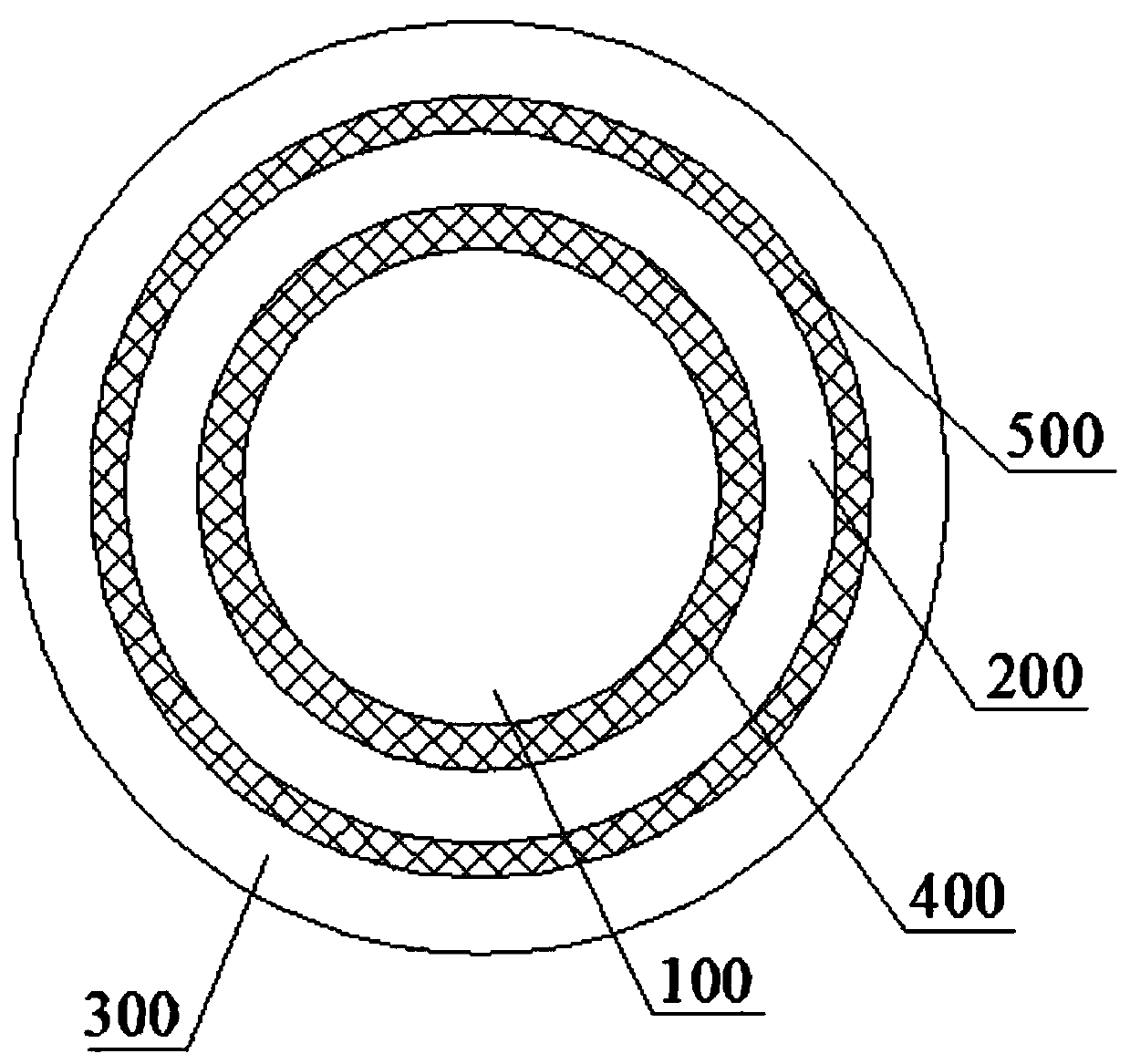

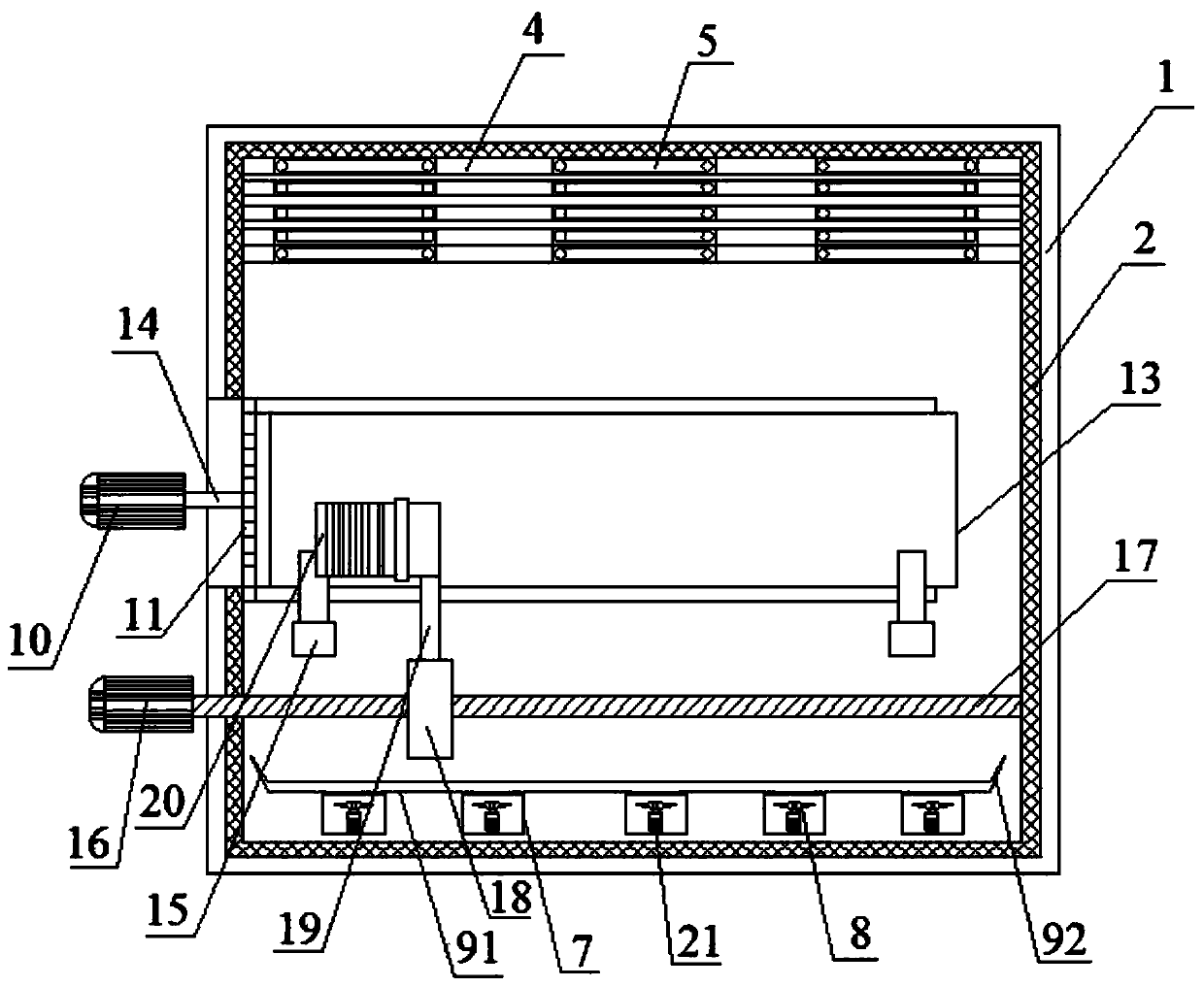

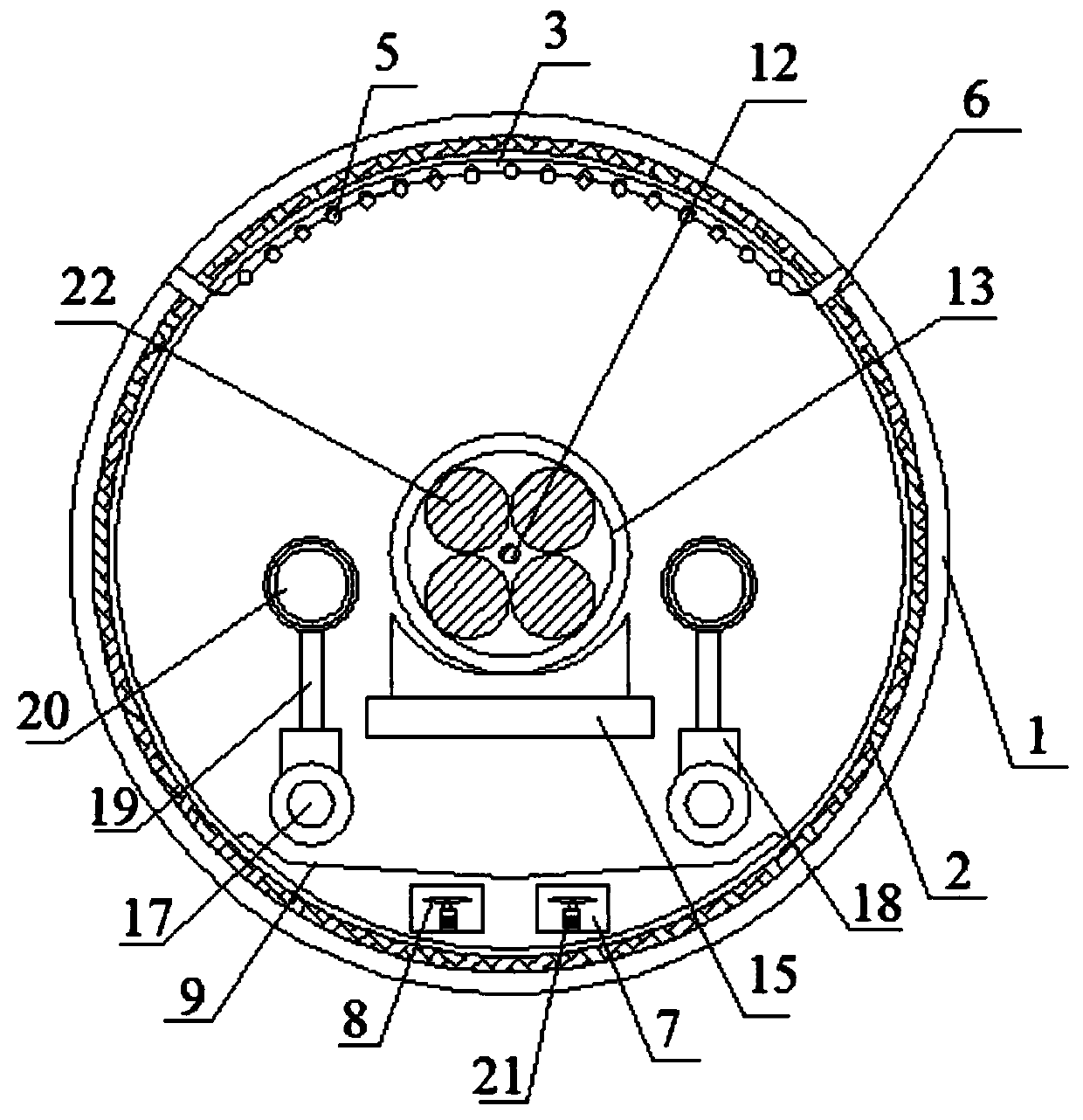

[0038] see Figure 1-4 As shown, this embodiment provides a glass fiber reinforced PE water supply pipe, which is composed of an inner layer 100, a core layer 200 and an outer layer 300. An inner transitional strengthening layer 400 is provided between the inner layer 100 and the core layer 200. The core An outer transition reinforcement layer 500 is provided between the layer 200 and the outer layer 300, and the core layer 200 is a wound pre-treated glass fiber tape layer;

[0039] Wherein, the inner layer 100 includes the following raw materials in parts by weight: 96 parts of HDPE resin, 3.3 parts of trimethylolpropane triacrylate, 17 parts of glass fiber, 1.9 parts of nano-silver antibacterial agent, 2.5 parts of lubricant magnesium stearate, 2.1 parts of expanded graphite;

[0040] The outer layer 300 includes the following raw materials in parts by weight: 107 parts of HDPE resin, 3.6 parts of trimethylolpropane triacrylate, 14 parts of glass fiber, 1.8 parts of nano-si...

Embodiment 2

[0053] see Figure 1-4 As shown, this embodiment provides a glass fiber reinforced PE water supply pipe, which is composed of an inner layer 100, a core layer 200 and an outer layer 300. An inner transitional strengthening layer 400 is provided between the inner layer 100 and the core layer 200. The core An outer transition reinforcement layer 500 is provided between the layer 200 and the outer layer 300, and the core layer 200 is a wound pre-treated glass fiber tape layer;

[0054] Wherein, the inner layer 100 includes the following raw materials in parts by weight: 96 parts of HDPE resin, 3.5 parts of trimethylolpropane triacrylate, 18 parts of glass fiber, 2.4 parts of nano-silver antibacterial agent, 2.5 parts of lubricant polyethylene wax, expansion 2.2 parts of graphite;

[0055] The outer layer 300 includes the following raw materials in parts by weight: 109 parts of HDPE resin, 3.6 parts of trimethylolpropane triacrylate, 15 parts of glass fiber, 2.0 parts of nano-sil...

Embodiment 3

[0063] see Figure 1-4 As shown, this embodiment provides a glass fiber reinforced PE water supply pipe, which is composed of an inner layer 100, a core layer 200 and an outer layer 300. An inner transitional strengthening layer 400 is provided between the inner layer 100 and the core layer 200. The core An outer transition reinforcement layer 500 is provided between the layer 200 and the outer layer 300, and the core layer 200 is a wound pre-treated glass fiber tape layer;

[0064]Wherein, the inner layer 100 includes the following raw materials in parts by weight: 98 parts of HDPE resin, 3.5 parts of trimethylolpropane triacrylate, 19 parts of glass fiber, 2.4 parts of nano-silver antibacterial agent, 2.8 parts of lubricant magnesium stearate, 1.9 parts of expanded graphite;

[0065] The outer layer 300 includes the following raw materials in parts by weight: 108 parts of HDPE resin, 3.6 parts of trimethylolpropane triacrylate, 16 parts of glass fiber, 2.1 parts of nano-sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com