Application of basalt fiber fabric in photothermal conversion

A technology of basalt fiber and light-to-heat conversion, which is applied to the components of solar collectors, solar thermal energy, solar thermal power generation, etc., can solve problems such as unstable performance, achieve long service life, high tensile strength, and good application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The basalt fiber fabric of the present invention is a plain or twill basalt fiber fabric, in which the fibers are arranged in a cross in the warp and weft directions, and the edges of the basalt fiber fabric are edge-locked with cotton thread.

[0025] The present invention prepares the basalt fiber fabric by weaving in the weft direction, wherein the continuous basalt fiber passes through a rapier dobby carbon fiber weaving machine and uses weaving weaving technology to make plain or twill basalt fabric.

[0026] The preparation steps of basalt fiber fabric are as follows:

[0027] (1) First hang the continuous basalt fiber reel on the creel, and lead the yarn end out of the yarn guide hole of the creel respectively;

[0028] (2) Then the basalt fiber outside the yarn guide hole is intensively drawn to the yarn guide device of the rapier type dobby fiber braiding machine;

[0029] (3) Each basalt fiber is reeded, grouped and knotted, and introduced into the braiding m...

Embodiment 2

[0037] The difference with embodiment 1 is:

[0038] In the application of photothermal conversion of basalt fiber fabrics, the experimental process of modifying basalt fiber fabrics is added. Specifically, the basalt fiber fabrics are placed in a tube furnace and heated at a rate of 2°C / min in an argon atmosphere. 500°C, constant temperature for 180min and then cooling to room temperature at a rate of 2°C / min to obtain the modified basalt fiber fabric.

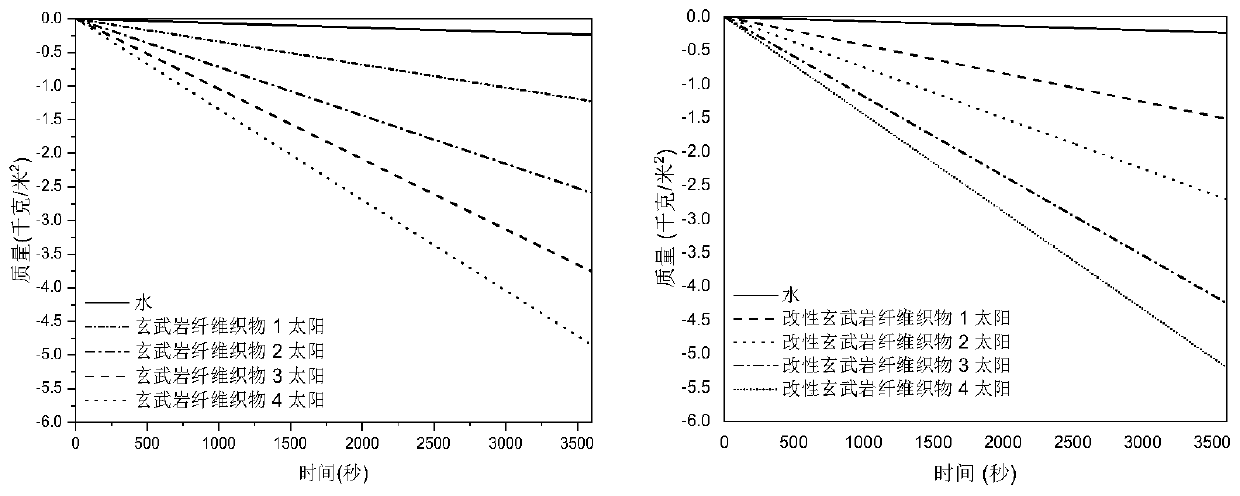

[0039] The photothermal efficiency of the basalt fiber fabric of comparative embodiment 1 and the modified basalt fiber fabric of embodiment 2 under different sunlight, such as image 3 It can be seen from the curve that the seawater evaporation efficiency of basalt fiber photothermal fabric is 1.2kg / m under one sunlight 2 h, after modification it can reach 1.5kg / m 2 h, under four sunlights, the evaporation efficiency is 4.9kg / m 2 h and 5.4kg / m 2 h, indicating that the light and hot water evaporation efficiency of the mod...

Embodiment 3

[0043] The difference with embodiment 1 is:

[0044] In the application of photothermal conversion of basalt fiber fabrics, the experimental process of modifying basalt fiber fabrics is added. Specifically, the basalt fiber fabrics are placed in a tube furnace and heated at a rate of 2°C / min in an argon atmosphere. 500°C, constant temperature for 180min and then cooling to room temperature at a rate of 2°C / min to obtain the modified basalt fiber fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com