High-precision and high-reliability composite film electrode thermosensitive chip

A composite thin-film, high-precision technology, applied to thermistors, resistor terminals/electrodes, resistors with negative temperature coefficients, etc., can solve the problems of cumbersome process, large thickness of silver electrode layer, uneven coverage, etc., to achieve The effect of saving metal materials, high chemical stability, and avoiding harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

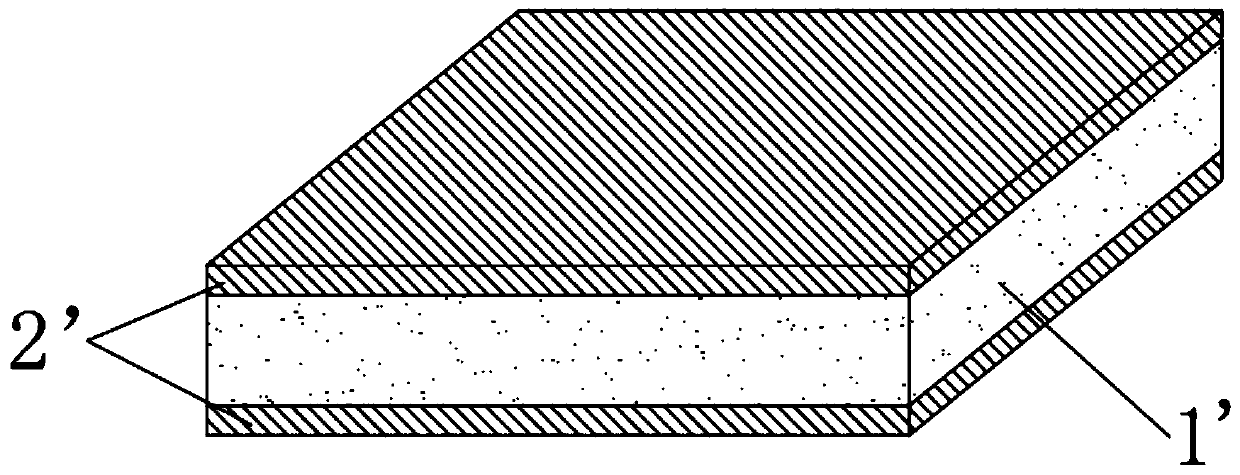

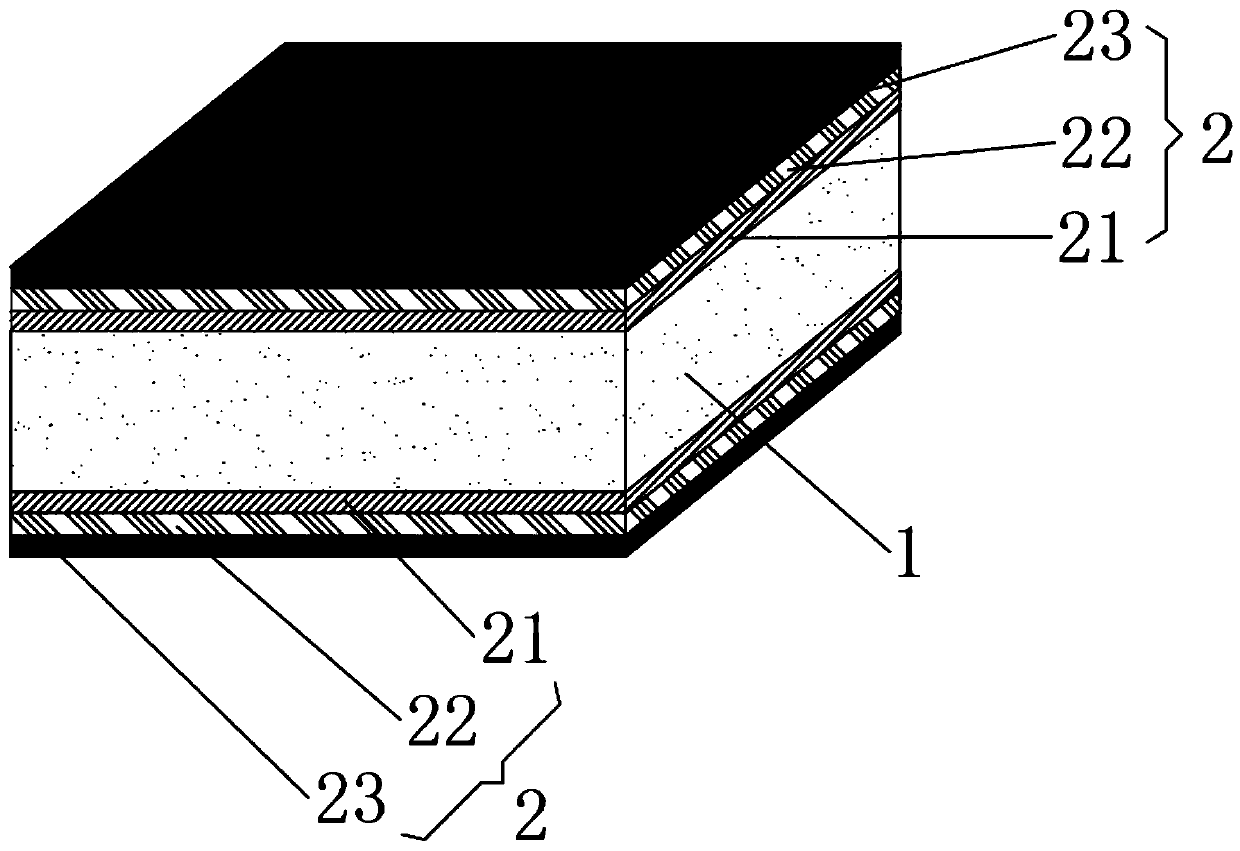

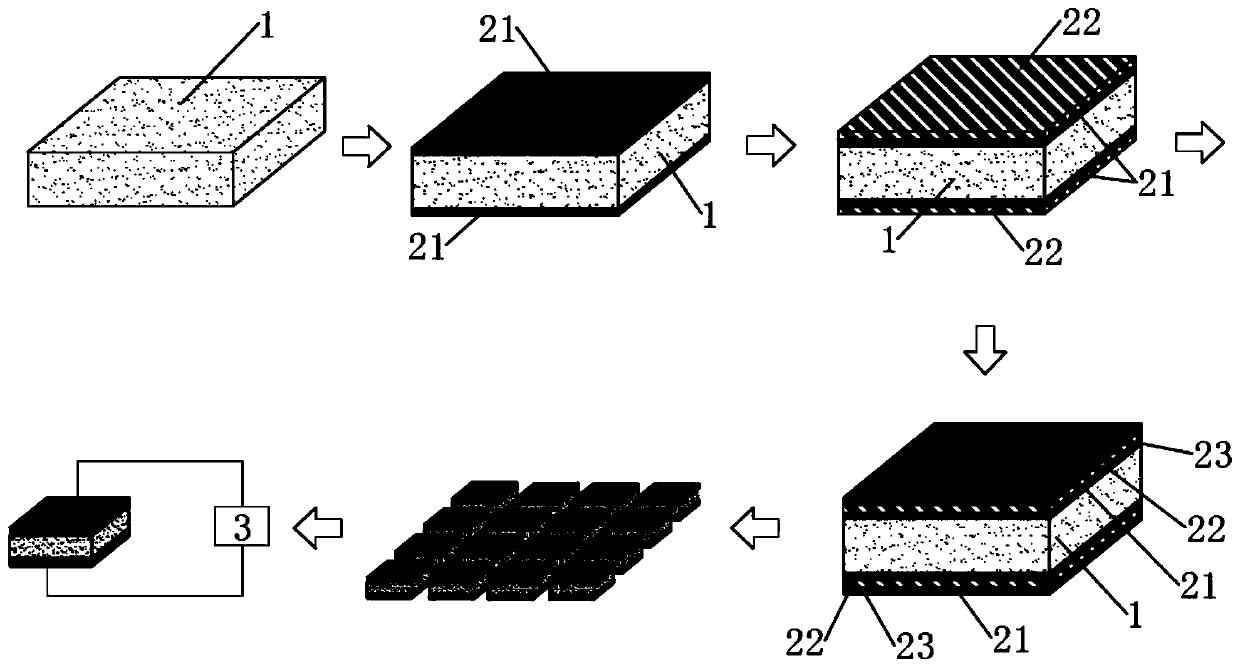

[0030] see figure 2 , which is a schematic structural view of the composite thin film electrode thermosensitive chip of the present invention.

[0031] The composite thin film electrode thermosensitive chip of the present invention comprises thermosensitive ceramic substrate 1 and two composite thin film electrodes 2 that are respectively arranged on the two surfaces of described thermosensitive ceramic substrate 1, and described composite thin film electrode 2 is made of stainless steel layer 21. A copper layer 22 and a gold layer 23 are laminated sequentially on the surface of the heat-sensitive ceramic substrate 1 from inside to outside.

[0032] Specifically, the thickness of the stainless steel layer 21 is 0.01-2 microns; the thickness of the copper layer 22 is 0.01-2 microns; and the thickness of the gold layer 23 is 0.01-1 microns. Preferably, the stainless steel layer 21 has a thickness of 0.4 microns, the copper layer 22 has a thickness of 0.4 microns, and the gold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com