Preparation method of copper-based fluoride solid solution sodium ion battery positive electrode material

A technology for sodium ion batteries and cathode materials, which is applied in the preparation of fluoride, battery electrodes, chemical instruments and methods, etc., can solve the use of electrode materials that cannot be used in secondary batteries, the self-stability is not excellent enough, and the growth rate of copper element is fast, etc. The problem is to achieve the effect of inhibiting the growth of copper particles, excellent electrochemical performance, and simple and convenient synthesis route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 10.01g copper fluoride (CuF 2 , purity greater than 97%) and 9.38g ferrous fluoride (FeF 2 Purity greater than 97%) was added to a 150ml zirconia ball mill jar, zirconia balls were used as the grinding medium, the ball-to-material ratio was 2:1, and a sealing film was used to seal the ball mill jar. Assemble the ball mill jar on a high-energy ball mill, and perform ball milling at a speed of 250r / min for 10 hours. After ball milling, a solid solution of copper fluoride and ferrous fluoride (Cu 0.5 Fe 0.5 f 2 ). According to Cu 0.5 Fe 0.5 f 2 The mass ratio of the solid solution is to add 5% Ketjen black (KB) relative to the mass of fluoride in the ball milling jar, seal the ball milling jar, and mill at a speed of 200r / min for 4h to obtain Cu 0.5 Fe 0.5 f 2 @C Composite electrode materials.

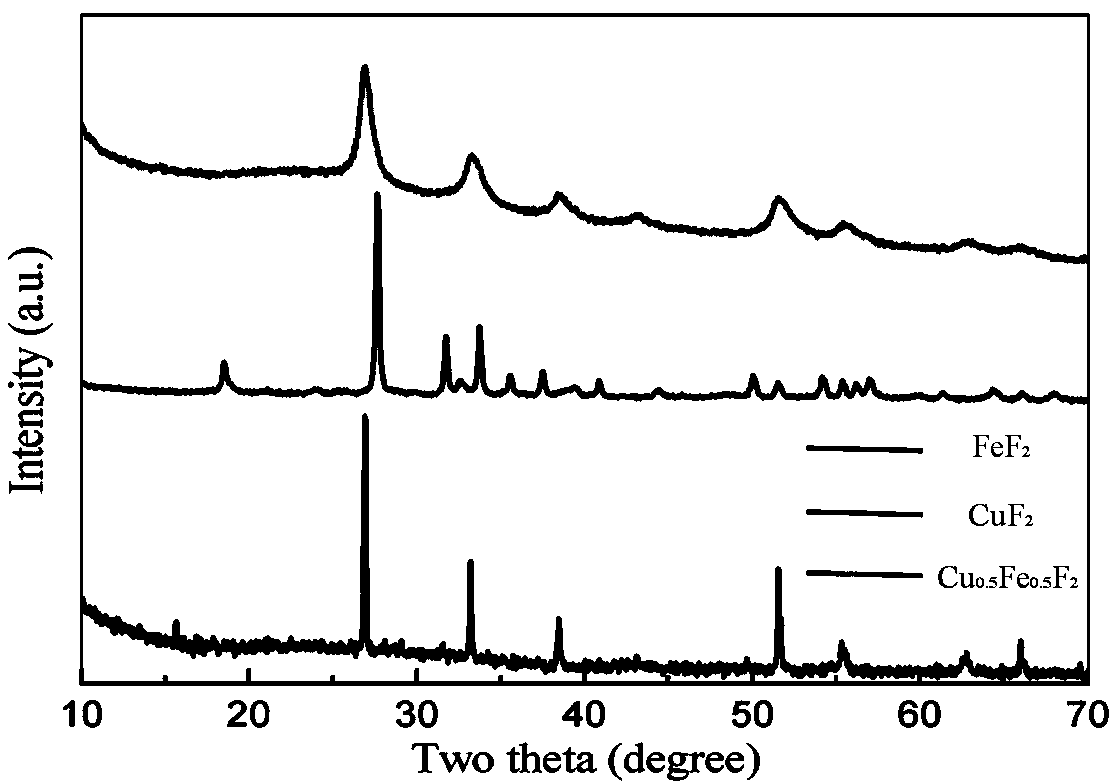

[0021] figure 1 , image 3 with Figure 5 The test results show that the electrode material synthesized according to this method is pure phase Cu 0.5 Fe 0.5 f 2 Sol...

Embodiment 2

[0023] According to the method in embodiment 1 FeF 2 The powder is replaced with the same molar amount of NiF 2 , can get Cu 0.5 Ni 0.5 f 2 Fluoride solid solution and Cu 0.5 Ni 0.5 f 2 Composite electrode materials of @C.

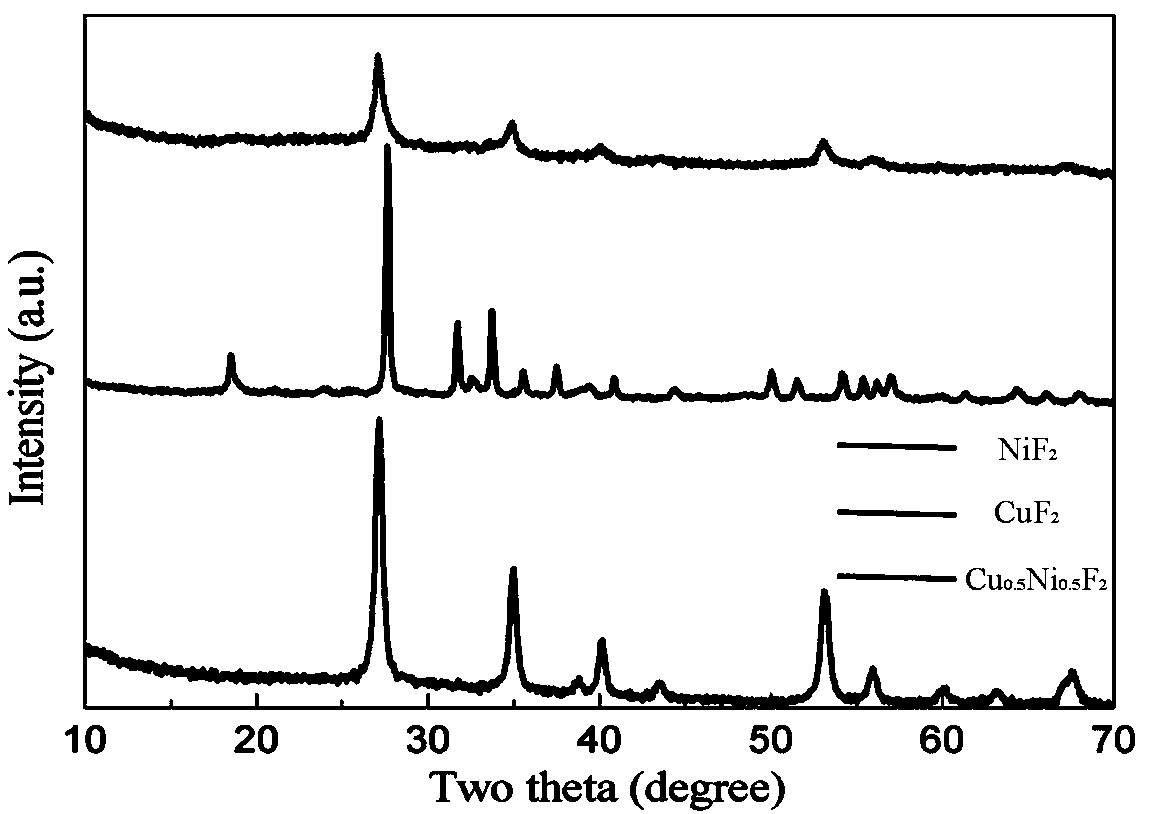

[0024] figure 2 , Figure 4 The test results show that the electrode material synthesized according to this method is a pure phase Ni0.5Fe0.5F2 solid solution without CuF 2 Monomer phase.

Embodiment 3

[0026] Regulate MF 2 Fluoride monomer molar ratio, the same method can be used to obtain a series of copper-based fluoride sodium ion battery electrode material Cu with different copper content x m y f 2 , where the value of xy must satisfy x0.1.

[0027] The present invention mainly consists of CuF 2 as the basic material CoF 2 , FeF 2 、NiF 2 and other fluorides through the method of high-energy ball milling to synthesize copper-based fluoride solid solution positive electrode materials, and FeF 2 with CuF 2 Prepared as a solid solution, it can reduce the self-polarization of the iron-based fluoride, and at the same time inhibit the growth of copper elemental particles during the discharge process, and overcome the shortcomings of the two materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com