Vacuum moisture regaining control process for tobacco leaf processing quality homogenization, energy conservation and consumption reduction

A vacuum moisture resurfacing and tobacco leaf processing technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of elongated equipment operation period, waste of energy, increase of processing cost, etc., to solve the problem of inconsistent processing intensity, reduce moisture coefficient of variation, improve Effect of Moisture Homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

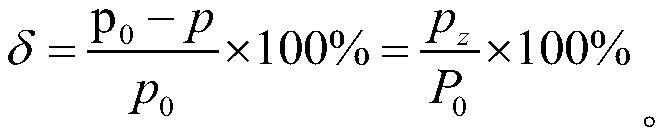

[0020] The present invention can realize a stable constant loading rate and a stable constant deformation rate. The pressure sensor is used as a pressure measuring device, and the relative error of the force indication can be kept unchanged through the pressure sensor and the corresponding electronic amplification circuit. Improving the quality of the pressure sensor and the corresponding electronic amplification circuit can greatly improve the measurement accuracy of the pressure.

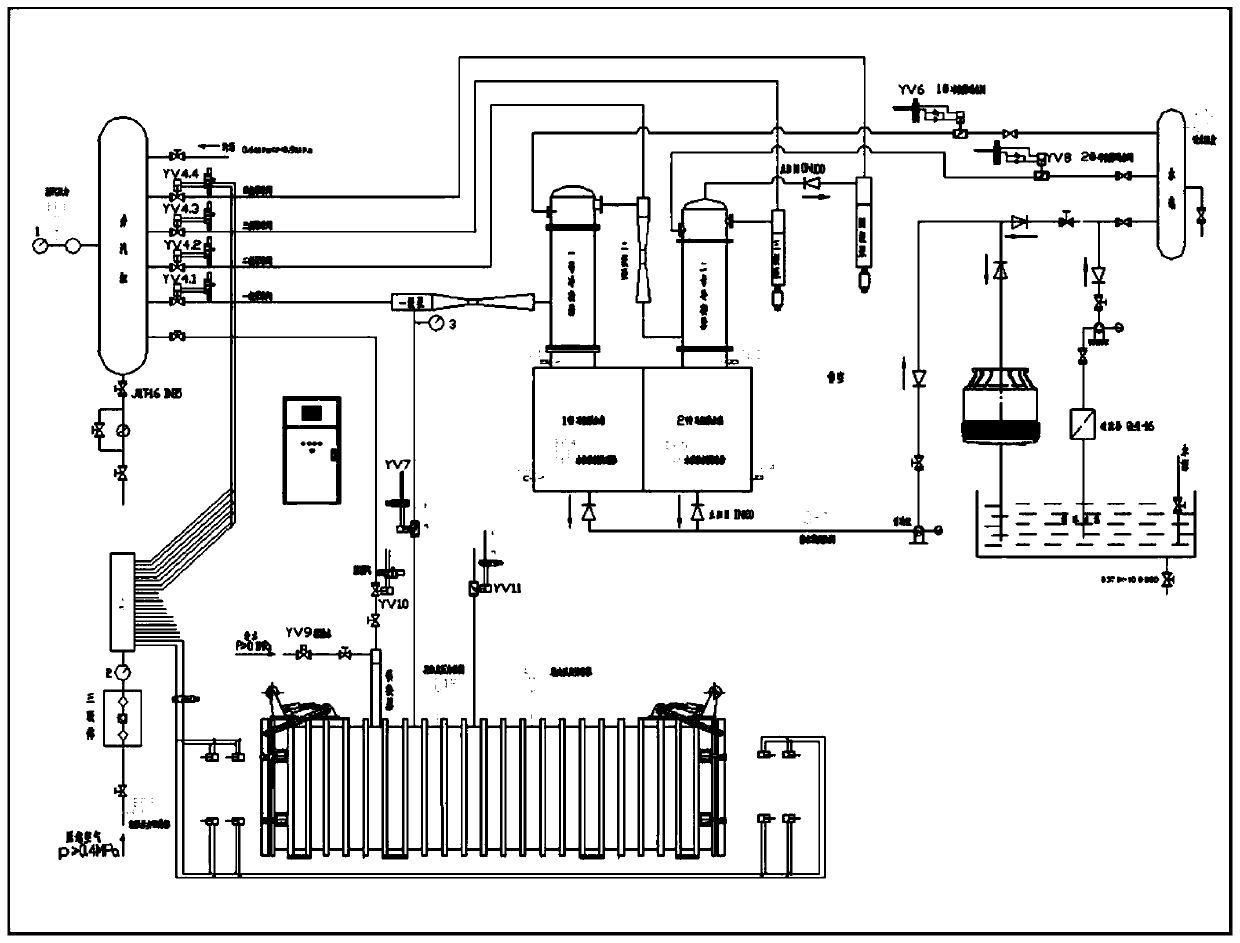

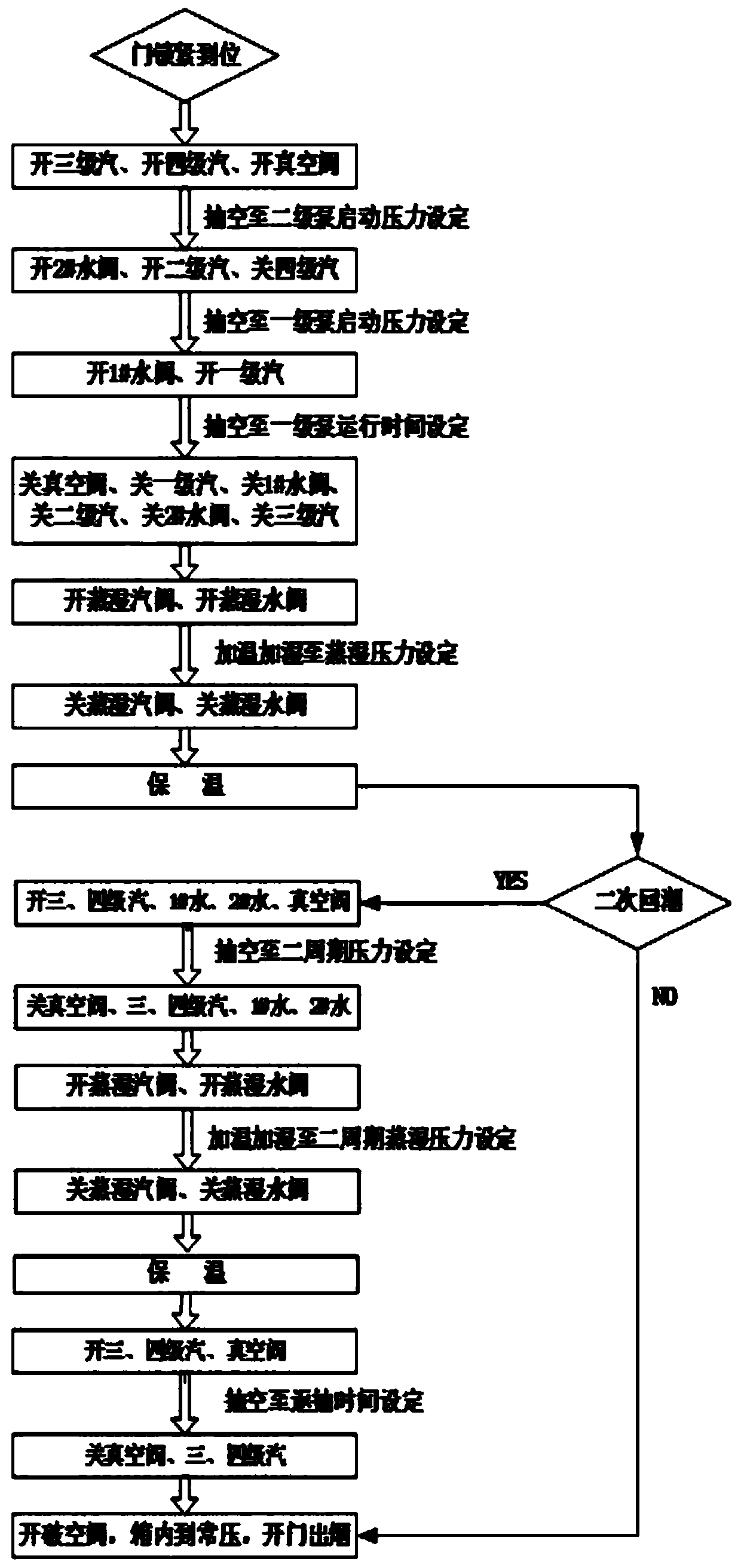

[0021] Such as Figure 1-2 As shown, the control process includes vacuum dampening equipment. The vacuum dampening equipment has software and hardware configurations. Among them, the vacuum dampening equipment is mainly composed of a vacuum box, a door mechanism for a switch box, a vacuum system, a steaming system, and a steam distribution system. , compressed air system, cooling water circulation system, electric control system, etc.; the vacuum resurgence equipment has no negative pressure monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com