Ceramic coating for surface of energy-gathering ring of gas stove and preparation method and application method thereof

A technology of ceramic coatings and energy-gathering rings, which can be applied to devices for coating liquids on surfaces, special surfaces, fire-resistant coatings, etc. Good sex and good coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059]The pH value is very critical to the preparation of ceramic coatings. The performance and service time of ceramic coatings will be very different when reacting at different pH values. In order to ensure the accuracy of the pH value during the system reaction, the amount of organic acid added to the catalyst must be accurate. It works, because the catalyst organic acid is added in a small amount in the paint, adding it alone will easily cause a large error, and the pH value of the reaction will have a large error. Adding it after diluting it with deionized water can reduce the error of catalyst addition, which is beneficial The control of the pH value of the ceramic coating reaction enables the ceramic coating to achieve the desired performance.

[0060] The preparation method of the ceramic coating for the surface of the gas stove energy gathering ring of the present invention comprises the following steps:

[0061] (1) Preparation of component A

[0062] After mixing t...

Embodiment 1

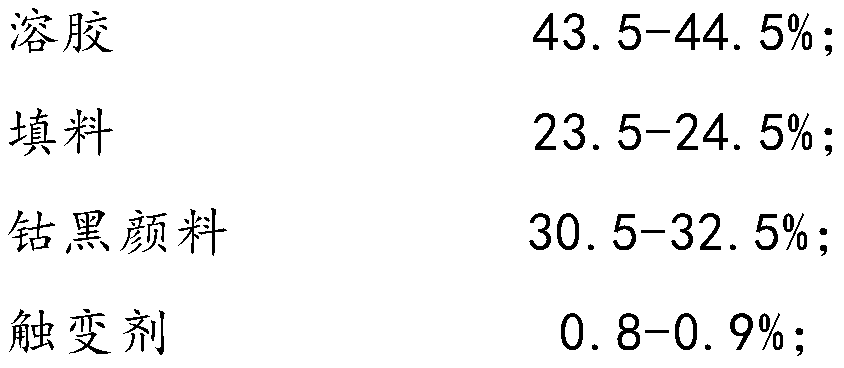

[0074] Each component and content thereof are as shown in table 1 in embodiment 1:

[0075] Components and content thereof in Table 1 Example 1

[0076]

[0077] 1. Preparation of component A: After mixing the sol, pigment, filler and deionized water evenly, grind on a basket grinder for 1.5 hours until the fineness reaches about 25um, add cellulose, grind for 30 minutes, then add BYK405, and grind again After 30 minutes, the fineness reaches 15 μm, and the material is discharged after filtering with a 300-mesh filter cloth to obtain component A.

[0078] 2. Preparation of ceramic coatings: Add component C to component B, mix well, add to component A color paste, mix well, and roll on the roller rack for 4 hours to get ceramic coating, the ceramic coating Tu-4 cup viscosity is 12.86s, pH value is 4.2, use up within 72 hours.

[0079] 3. Coating production construction parameters: substrate roughness 2.5μm, preheat to 40℃, curing temperature 200℃, 10 minutes, coating film ...

Embodiment 2

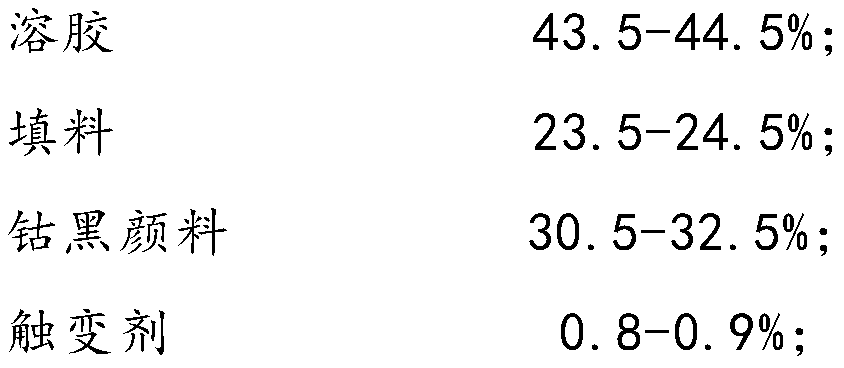

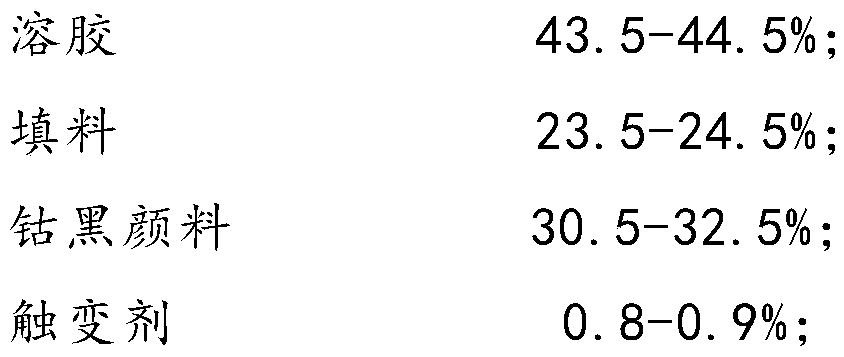

[0084] Each component and content thereof are as shown in table 2 in embodiment 2:

[0085] Components and content thereof in Table 2 Example 2

[0086]

[0087] 1. Preparation of component A: After mixing the sol, pigment, filler and deionized water evenly, grind on a basket grinder for 1 hour until the fineness reaches below 25um, add fumed silica, grind for 30 minutes, and then add BYK- 420, grind for 30 minutes, the fineness is below 15μm, filter with 300-mesh filter cloth and discharge to obtain component A.

[0088] 2. Preparation of ceramic coatings: Add component C to component B, mix well, add to component A color paste, mix well, and roll on the roller rack for 4 hours to get ceramic coating, the ceramic coating Tu-4 cup viscosity 12s, pH value 4.4, use up within 72hrs.

[0089] 3. Coating production construction parameters: substrate roughness 3μm, preheat to 40℃, curing temperature 200℃, 10 minutes, coating film thickness 35μm.

[0090] Performance Testing: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com