Catalytic cracking method and system for heavy oil feedstock

A technology of catalytic cracking and heavy oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc. It can solve the problems of reducing the dry gas yield and not producing low-carbon olefins, so as to improve economic and social benefits and promote The effect of transformational development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

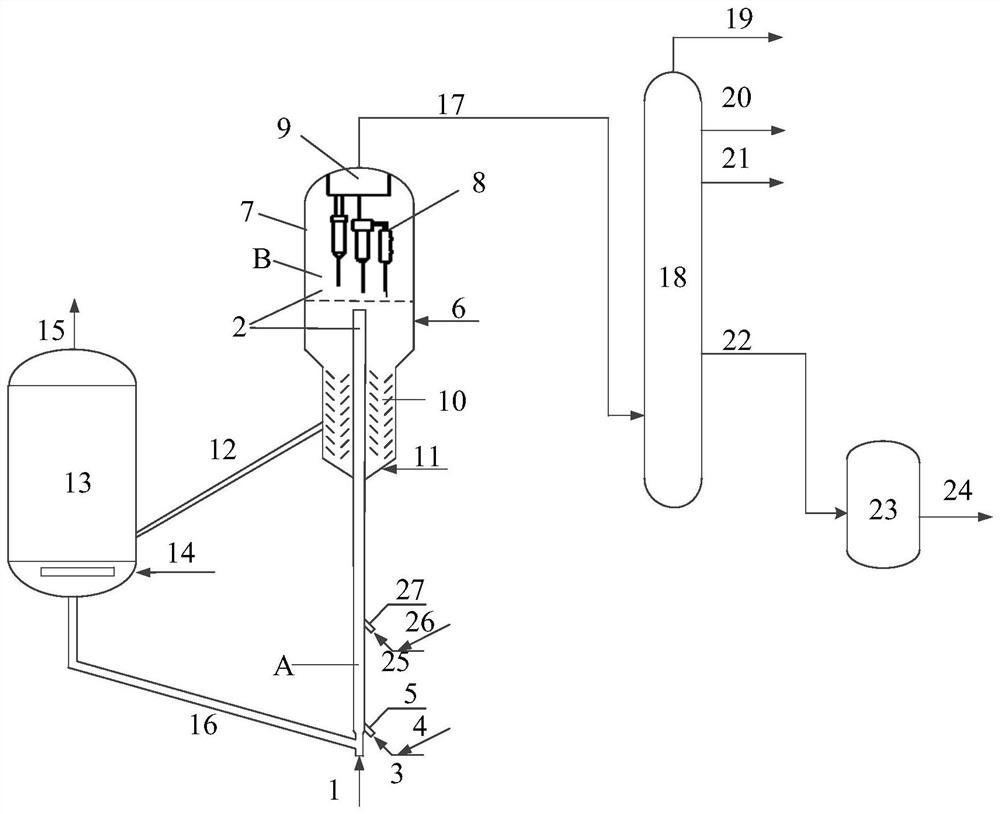

[0074]One embodiment, the first catalytic cracking reactor is a riser reactor, and the second catalytic cracking reactor is a fluidized bed reactor; the conditions of the first catalytic cracking reaction include: the reaction temperature is 550- 720°C, preferably 580-700°C, more preferably 620-690°C, the oil and gas residence time is 1-10 seconds, preferably 1.5-6 seconds, more preferably 1.5-4 seconds, and the reaction pressure is 0.13-1 MPa , preferably 0.25-0.4 MPa, the weight ratio of agent to oil is 1-100, preferably 10-50:1, more preferably 20-40:1, and the weight ratio of refining and cracking heavy gasoline to heavy oil raw materials is 0.05-0.7 ; The reaction temperature of the riser reactor refers to the outlet temperature of the riser reactor; the reaction pressure refers to the gauge pressure. The conditions of the second catalytic cracking reaction include: the reaction temperature is 530-730°C, preferably 560-680°C, more preferably 610-660°C, and the reaction ti...

preparation example 1

[0090] The preparation method of the hydrotreating catalyst used in the embodiment is as follows:

[0091] Using commercially available pseudo-boehmite as Al source, 3.5% HNO by weight 3 The aqueous solution is used as a binder, and an appropriate amount of Mg is introduced 2+ After extruding, it is dried at 120°C and calcined at 600°C to obtain a composition of 5% MgO and 95% Al 2 o 3 carrier.

[0092] Weigh 67g Ni(NO 3 ) 2 ·6H 2 O and 24g (NH 4 )6Mo 7 o 24 ·6H 2 O·4H 2 O was dissolved in 100g of distilled water, and 17g of NH 4 h 2 PO 4 , to which an appropriate amount of concentrated HNO was added dropwise 3 Dissolve the precipitate and adjust the pH value between 5-6 to form solution I; add 25g citric acid to solution I to form solution II; heat solution II to 70°C, dropwise add it to 1000g carrier while hot, and dry After drying, bake at 550°C for 8 hours. Catalyst before use in H 2 Reduction at 600°C for 12 hours. The catalyst weight composition is: 12%...

Embodiment 1

[0094] This example is used to illustrate the method of the present invention.

[0095] according to figure 1 The flow shown is tested, and the test is carried out on a medium-sized device. The heavy oil feedstock is atmospheric residue Z, the catalyst is catalyst MMC-2, and the preheated heavy oil feedstock (350°C) enters the bottom of the riser reactor that complies with the reactor. The reaction is carried out, and the reaction oil enters the fluidized bed reactor of the compound reactor from the outlet of the riser reactor to continue the reaction. After the reaction, the stream enters the closed cyclone separator, and the reaction product and the unborn catalyst are quickly separated, and the reaction product is further separated to obtain ethylene. , propylene, butene, and pyrolysis heavy gasoline M1 with a distillation range of 160-220°C.

[0096] The pyrolysis heavy gasoline M1 and the hydrotreating catalyst H are subjected to hydrotreating in the presence of a solven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com