SiC-Si3N4-carbon fiber compounded bullet-proof vest fabric and preparation method thereof

A body armor, carbon fiber technology, applied in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems affecting comfort, the combination of shear thickening liquid and three-dimensional bulletproof fabrics needs to be improved, and achieve strong bullet resistance. , Good marketing value, light quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

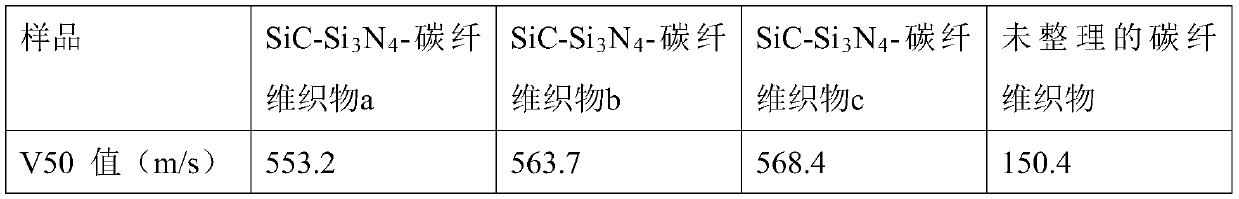

Examples

Embodiment 1

[0025] In this embodiment, a SiC-Si 3 N 4 -The carbon fiber composite body armor fabric is prepared by the following method, including the following steps:

[0026] (1) Preparation of SiC sol: Mix 35mL of absolute ethanol, 35mL of deionized water and 15mL of 10% hydrochloric acid aqueous solution to prepare mixed solution a; dissolve 10g of tetraethoxysilane and 125mL of phenolic resin in 400mL of absolute ethanol, Mixed solution b is obtained; mixed solution a is slowly added dropwise to mixed solution b, and the dropwise addition time is 2 hours; after the dropwise addition is completed, stir for 2 hours; after the stirring is completed, leave it to stand and age for 5 hours; the temperature of the whole process control system is : 80°C; a sol was obtained.

[0027] (2) Preparation of perhydropolysilazane precursor: In a three-necked flask, mix 40mL of pyridine and 40mL of ethanol, and inject dichlorosilane gas into the mixture at a volume of 3mL / min for 1.5 hours , stirr...

Embodiment 2

[0031] In this embodiment, a SiC-Si 3 N 4 -The carbon fiber composite body armor fabric is prepared by the following method, including the following steps:

[0032] (1) Preparation of SiC sol: Mix 30 mL of absolute ethanol, 30 mL of deionized water and 10 mL of 10% hydrochloric acid aqueous solution to prepare mixed solution a; dissolve 10 g of tetraethoxysilane and 100 mL of phenolic resin in 300 mL of absolute ethanol, Mixed solution b is prepared; mixed solution a is slowly added dropwise to mixed solution b, and the dropping time is 1 hour; after the dropwise addition is completed, stir for 2 hours; after the stirring is completed, leave it to stand and age for 5 hours; the temperature of the whole process control system is : 70°C; a sol was obtained.

[0033] (2) Preparation of perhydropolysilazane precursor: In a three-necked flask, mix 30 mL of pyridine and 30 mL of ethanol, and inject dichlorosilane gas into the mixture at a volume of 2 mL / min for 1 hour , stirred a...

Embodiment 3

[0037] In this embodiment, a SiC-Si 3 N 4 -The carbon fiber composite body armor fabric is prepared by the following method, including the following steps:

[0038] (1) Preparation of SiC sol: Mix 40 mL of absolute ethanol, 40 mL of deionized water and 20 mL of 10% hydrochloric acid aqueous solution to prepare a mixed solution a; dissolve 10 g of tetraethoxysilane and 150 mL of phenolic resin in 500 mL of absolute ethanol, Mixed solution b is obtained; mixed solution a is slowly added dropwise to mixed solution b, and the dropwise addition time is 3 hours; after the dropwise addition is completed, stir for 3 hours; after the stirring is completed, leave it to stand for aging for 5 hours; : 85°C; a sol was prepared.

[0039] (2) Preparation of perhydropolysilazane precursor: In a three-necked flask, mix 50mL of pyridine and 50mL of ethanol, and inject dichlorosilane gas into the mixture at a rate of 4mL / min for 2 hours , stirred at room temperature to form a sol, and the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com