Imitated jacquard printing process of real silk fabric

A printing process and fabric technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of complex process, lack of three-dimensional effect, too flat visual effect, etc., achieve obvious color contrast, increase three-dimensional effect, luxurious and gorgeous quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

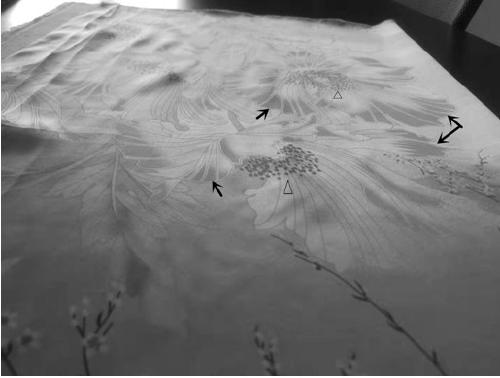

Image

Examples

Embodiment 1

[0036] Embodiments 1 to 3 are specific examples of the imitation jacquard printing process of a kind of real silk fabric of the present invention, wherein embodiment 1 is the best implementation mode.

[0037] The fabric used in Examples 1 to 3 is silk plain crepe satin. For reactive printing, imitation jacquard printing, and gold and silver printing, the equipment used is flat screen printing machine, which is Taiwan Qizheng KC-8000V ultra-wide cloth dynamic printing machine.

[0038] The reactive dyes used in the specific embodiment are all reactive dyes provided by Taixing Golden Pheasant Co., Ltd., Jiangsu Province, and the active groups are all monochloro-s-triazine / vinyl sulfone, mixed type;

[0039] The sodium alginate paste is provided by Qingdao Aoflon Biotechnology Co., Ltd.; the sodium alginate paste is composed of sodium alginate paste and water, and the mass ratio of sodium alginate paste and water is 10:80.

[0040] The anti-staining salt is sodium m-nitrobenzene ...

Embodiment 2

[0069] The name of the pattern in this example: Elegant Lily;

[0070] The present embodiment process comprises the following steps in turn:

[0071] Reactive printing: all colors are printed with 250-mesh pattern and printed with reactive paste;

[0072] 1.1) Printing dark brown, slurry formula: 2.1 parts of active ash, 1.4 parts of active scarlet, 0.03 parts of active golden yellow, 3 parts of baking soda, 1.5 parts of sodium m-nitrobenzenesulfonate, 6 parts of urea, 50 parts of sodium alginate paste, 20 parts of water;

[0073] 1.2) Crimson printing, slurry formula: 1.2 parts of reactive scarlet, 0.3 parts of reactive ash, 0.12 parts of reactive golden yellow, 2.2 parts of baking soda, and the weight of other components is the same as 1.1);

[0074] 1.3) Print dark green, slurry formula: 1.1 parts of active ash, 0.3 parts of active golden yellow, 0.05 parts of active golden yellow, 2.2 parts of baking soda, and the weight of other components is the same as 1.1);

[0075]...

Embodiment 3

[0090] The name of the flower type in this embodiment: Fuguihuakai;

[0091] The present embodiment process comprises the following steps in turn:

[0092] 1) Reactive printing: all colors are printed with 250-mesh pattern and printed with reactive paste;

[0093] 1.1) Printing black, slurry formula: 6 parts of reactive black ED-G, 1.3 parts of reactive red BPS, 0.7 parts of reactive golden yellow 3RS, 2.5 parts of baking soda, 0.5 parts of sodium m-nitrobenzenesulfonate, 10 parts of urea, sodium alginate 60 parts of paste, 0 parts of water;

[0094] 1.2) Printing bright red, slurry formula: 2 parts of reactive orange K-GN, 2.5 parts of reactive red K-BP, 0.7 parts of reactive orange P-2R; 3 parts of baking soda, and the weight of other components is the same as 1.1)

[0095] 1.3) Printed orange, paste formula: 2.7 parts of reactive golden yellow 3RS, 2.4 parts of reactive gray BPSN, 0.17 parts of reactive scarlet BPS, 2.9 parts of baking soda, and the weight of other compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com