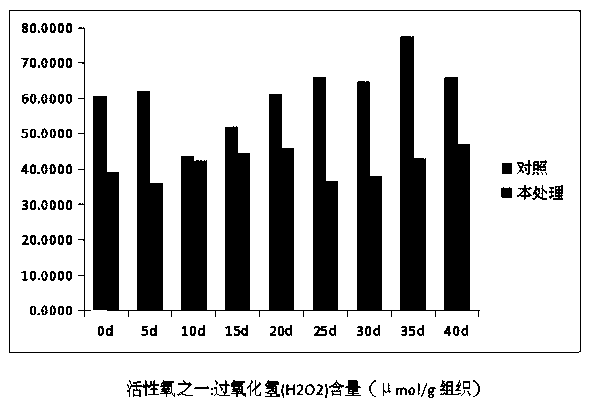

Bamboo shoot fresh-keeping method for inhibiting postharvest active oxygen damage

A fresh-keeping method and active oxygen technology, which is applied in the field of agricultural product storage, can solve the problems of quality reduction, low bamboo shoots, and no comprehensive consideration of the particularity of bamboo shoot preservation, so as to reduce quality deterioration, reduce bamboo shoot quality deterioration, and reduce microbial The effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Implementation 1: Preservation of bamboo shoots

[0039] 1) Selection of raw materials: From July to August, freshly harvested horseshoe shoots are purchased at the Pingyang Bamboo Shoot Base in Wenzhou. Fresh bamboo shoots with no pests and diseases on the shoots, no mechanical damage on the shoots, and neat and light yellow shells are selected. site.

[0040]2) Cleaning and shaping: put the selected bamboo shoots in a pool with a mesh screen at the bottom and rinse them with tap water, and the sediment will flow out through the screen; remove the aging and uneven parts of the base of the bamboo shoots, and peel off the loose shells of the bamboo shoots; Rinse with clean water, control the temperature of the cleaning water at 10°C-30°C by adding ice cubes, and control the entire cleaning time within 10 minutes.

[0041] 3) Preparation of hydrogen water and immersion: Use 99.99% filled hydrogen to connect a hose with an inner diameter of 3 mm to the bottom of the conta...

Embodiment 2

[0046] Implementation 2: Preservation of bamboo shoots in spring and winter

[0047] 1) Selection of raw materials: On March 15th, the spring and winter bamboo shoots of moso bamboo harvested on the same day were purchased in Xiaozhong Village, Suichang. Fresh bamboo shoots with no spots on the shoots, no mechanical damage, and bright shells were selected, and transported to the bamboo shoot processing plant.

[0048] 2) Cleaning and shaping: put the selected spring bamboo shoots in a sink with a mesh screen. The sink has a certain slope, and the running water washes the base and the sediment on the surface of the bamboo shoot shell; Bamboo shoot shells that are not tightly wrapped; then rinse with clean water and tap water. At that time, the temperature of the tap water is between 12°C and 18°C, and the entire cleaning time is 8 minutes.

[0049] 3) Preparation of hydrogen water and soaking: Use a hydrogen generator to make saturated hydrogen water, the water is pure water in...

Embodiment 3

[0056] Implementation 3: Preservation of winter bamboo shoots

[0057] 1) Selection of raw materials: The initial raw materials are winter bamboo shoots excavated from Baofu Town, Anji County, Zhejiang Province at the end of November. Bamboo shoots with no erosion spots on the shoots and bright shells are selected, and they are transported to the test site 3 hours after harvesting to start subsequent processing .

[0058] 2) Cleaning and shaping: Wash the selected bamboo shoots in the sink of the washing machine to wash off the surface sediment; artificially trim the base of the bamboo shoots to make them smooth, and peel off the outer shells that are not tight; then rinse with clean water and use for cleaning. The tap water temperature is about 10°C, and the entire cleaning time is 10 minutes.

[0059] 3) Preparation of hydrogen water and immersion: Use 99.99% filled hydrogen to connect a hose with an inner diameter of 3mm to the bottom of the container filled with tap water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com