Silicon removal device and silicon removal method

A regulating device and silicon dioxide technology, applied in chemical instruments and methods, special treatment targets, multi-stage water treatment, etc., can solve the problem of reducing the quality of electron tubes and solid circuits, affecting fiber strength and viscose viscosity, and making paper brittle and other problems, to achieve the effect of excellent silicon removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings.

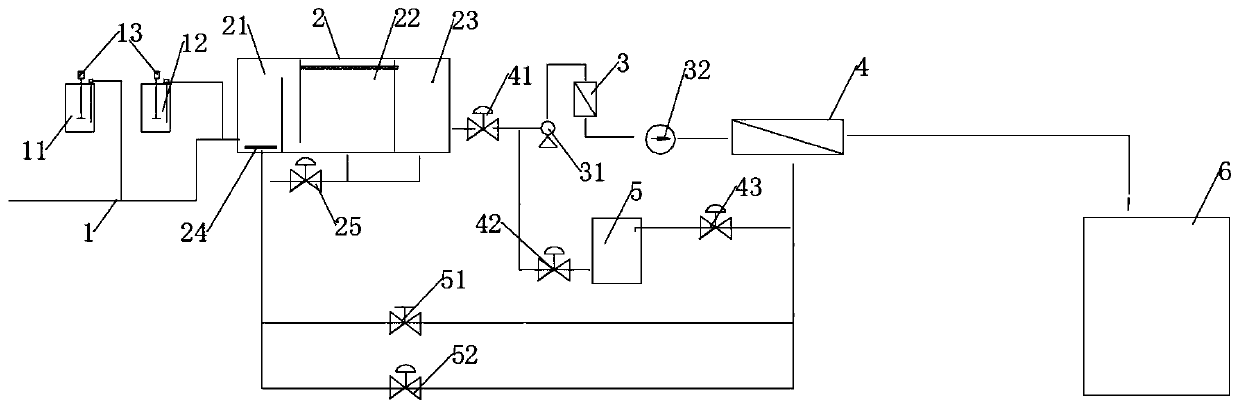

[0034] Such as figure 1 As shown, a silicon removal device of the present invention includes a silicon-containing wastewater dosing area 1, a silica reaction precipitator 2, a large-flux precision filter 3, an NF device 4, a cleaning water tank 5 and a product water tank 6;

[0035] The silicon-containing wastewater dosing area 1 is connected to a silica reaction precipitator 2 through a pipeline, and the silica reaction precipitator 2 is connected to a large flux precision filter 3 and a NF device 4 in sequence through a pipeline, and the NF device 4 Connected product water tank 6;

[0036] The silica reaction precipitator 2 includes a reaction zone 21, a settling zone 22 and a water purification zone 23. A water distributor 24 is arranged in the reaction zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com