Microbial self-repairing method for tunnel lining concrete cracks

A microbial remediation and microbial technology, which is applied in the intersection of microbiology and civil engineering materials, can solve the problems of reduced microbial survival and loss of self-healing effect, and achieves the effect of delaying the deterioration process, convenient operation and prolonging the effective survival period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of microbial remediation agent, its specific steps are as follows:

[0046] (1) After activating Bacillus colii, inoculate it into a liquid medium, then cultivate it for 32 hours at a temperature of 35° C. to obtain a bacterial liquid, and then centrifuge the obtained bacterial liquid with a centrifuge at a speed of 4000 r / min for 30 min to obtain Bacterial slime, the composition of the above liquid medium is: ultrapure water 1L, yeast powder 5g, trimethylglycine 4.5g, tryptone 10g, ammonium sulfate 5g, glutamic acid 2g, urea 10g;

[0047] (2) Dilute the sludge with sterilized distilled water to a concentration of 5.5×10 7 cells / mL, make a bacterial suspension, and add trioctyl phosphate and triallylamine with a content of 1wt‰ and 1wt‰ respectively, crush the carrier coral reef calcareous sand to a particle size of 2mm, and then put it into the bacterial suspension , put the bacterial suspension under the pressure of -0.07MPa and soak for 32 hours...

Embodiment 2

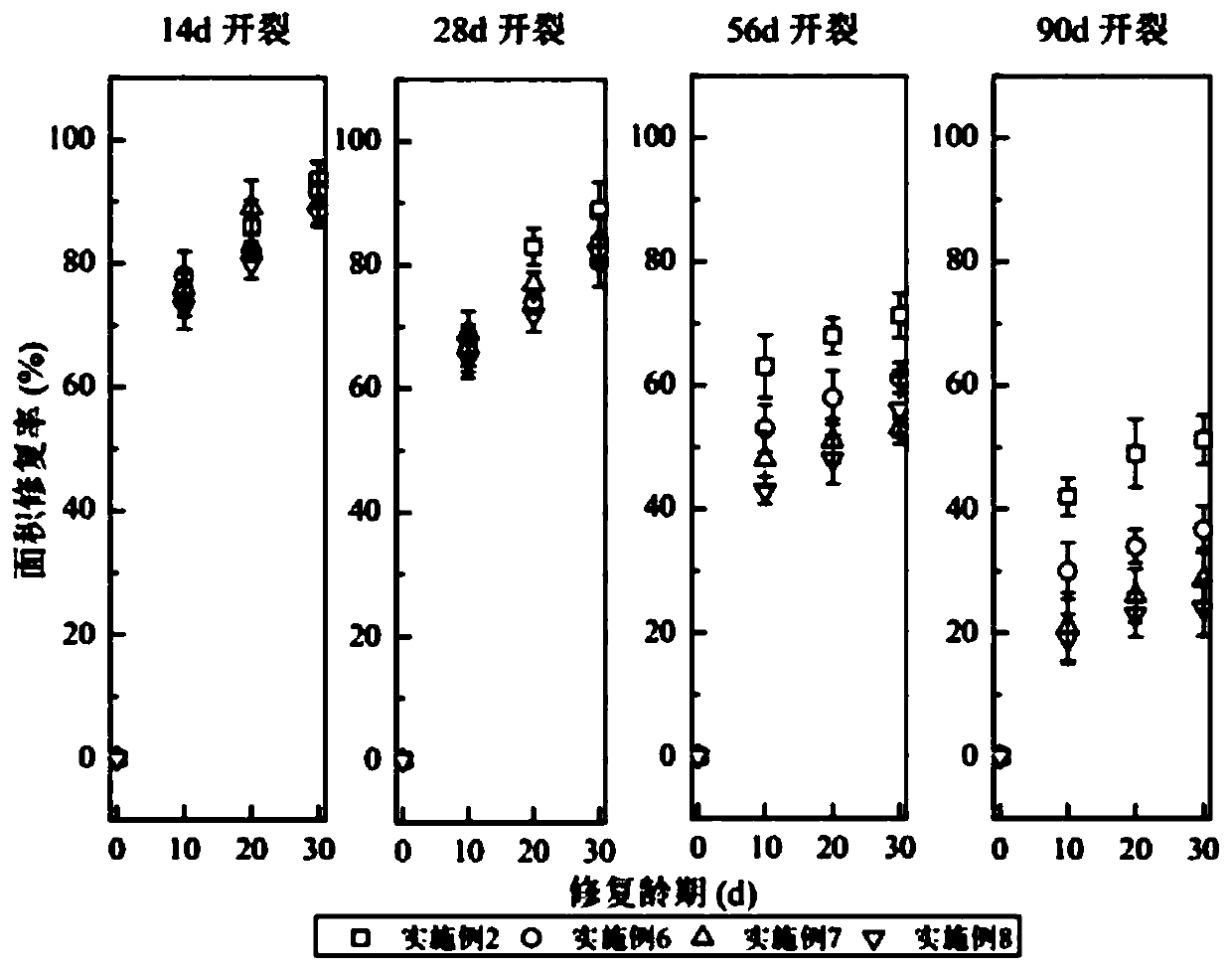

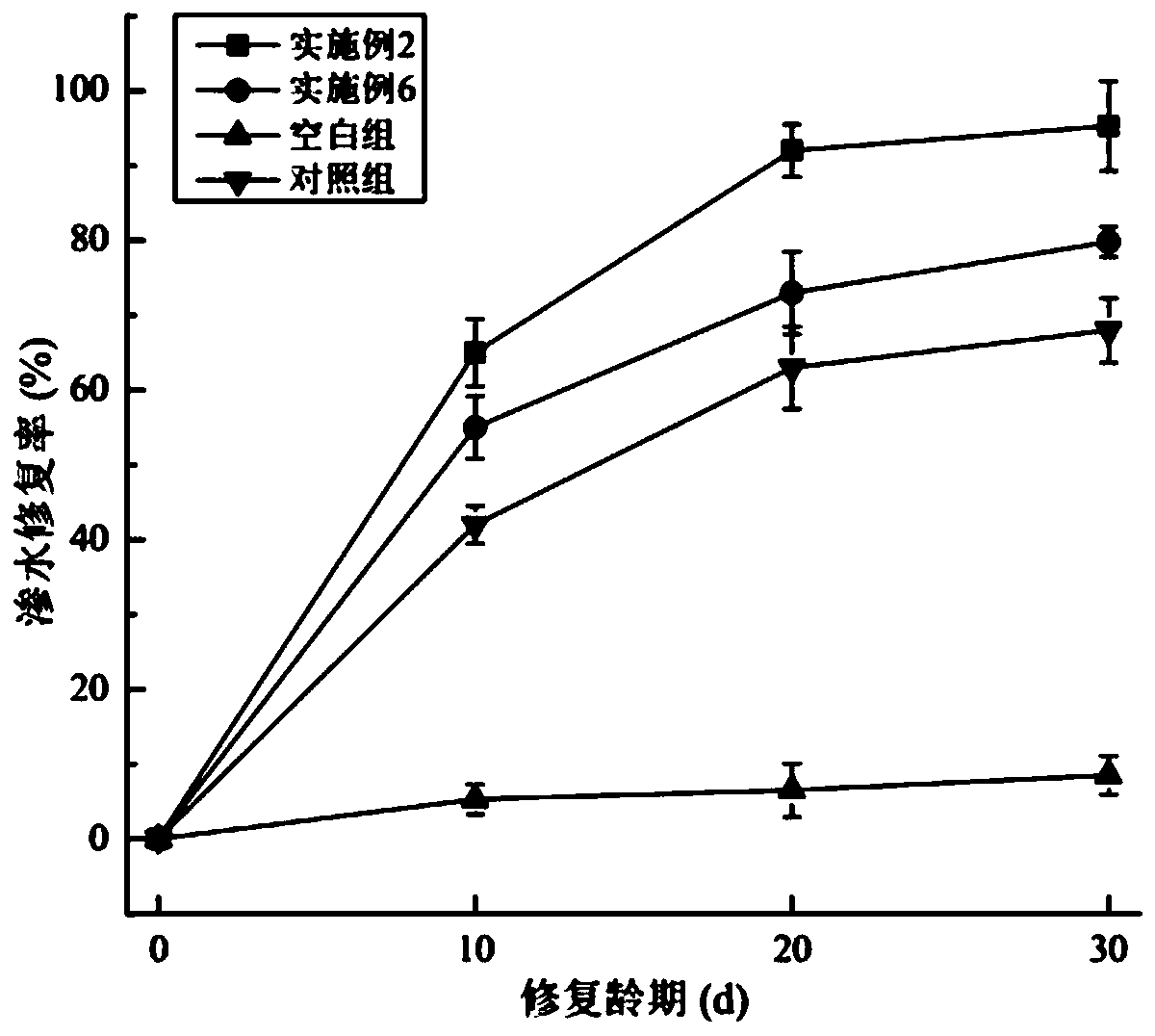

[0051] A microbial self-repair method for tunnel lining concrete cracks, the specific steps are as follows:

[0052] (1) Put cement, natural stone, sand, silica fume, calcium chloride, polypropylene fiber, water reducing agent and water into the mixer, and stir evenly;

[0053] (2) Then put the microbial restoration agent prepared in Example 1 into it, and then stir for 2 minutes, put the mixed concrete into the mould, and perform natural maintenance to obtain the tunnel lining concrete with the function of microbial self-repairing cracks. The weight ratio of the agent in the concrete is 13%.

Embodiment 3

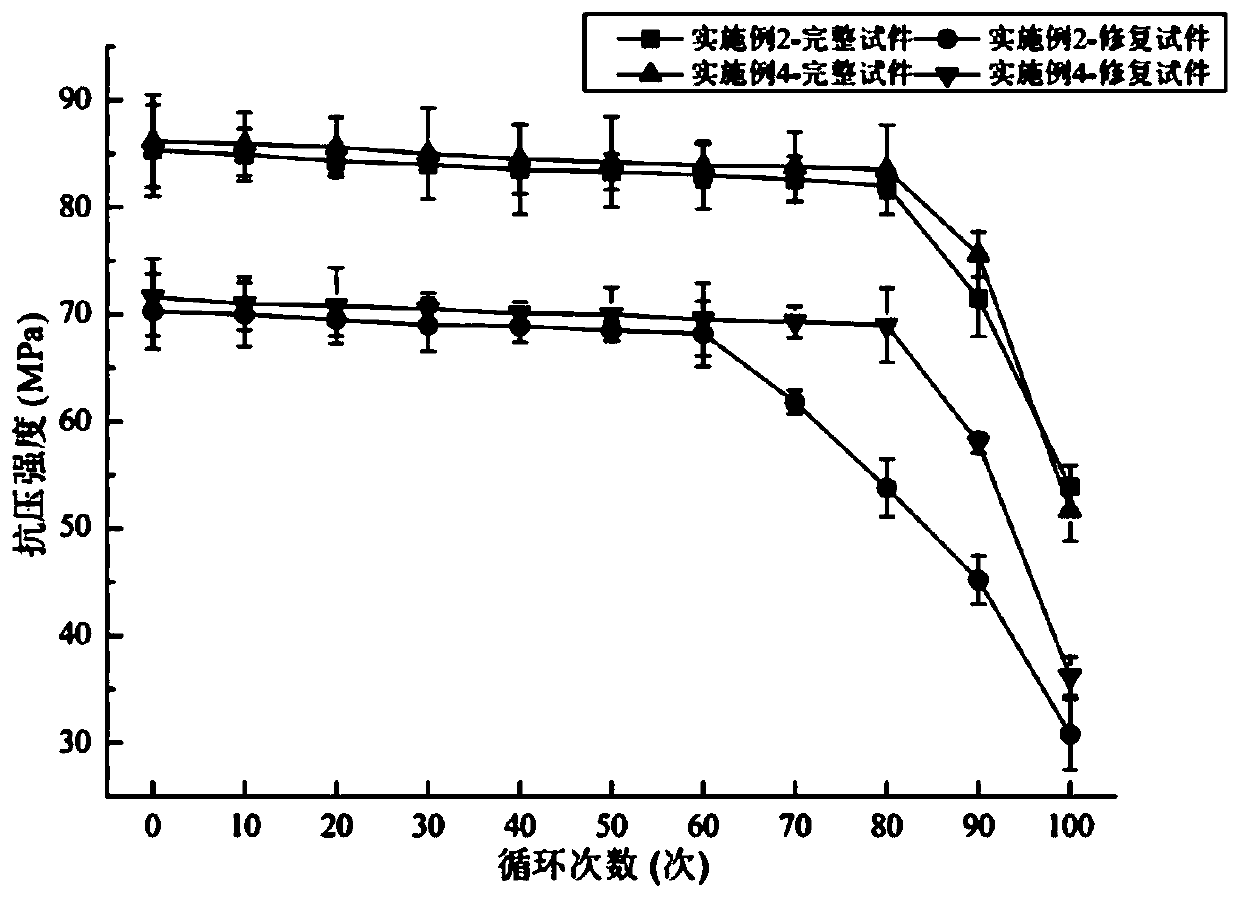

[0055] A preparation method of a microbial remediation agent, the only difference between this embodiment and Example 1 is that the protective layer slurry used in step (4) also contains 0.05wt% phenylacetic acid-2-methylpropyl ester and 0.08wt% % of styrene oxide, after the two are adsorbed on the carrier, due to its hydrophobicity, the intermolecular arrangement of the protective layer material changes, and the hydrophobic group is arranged on the outermost side, which makes the hydrophilicity of the carrier significantly reduced and the hydrophobicity increased, thereby avoiding Bacteria or spores are revived in advance when they encounter water in concrete, and the dormant period is not affected by water seepage. In addition, they can also participate in the deposition of calcium carbonate after the carrier is broken, enhancing the impermeability of the cracks, and thus making the repaired concrete more resistant to freezing and thawing. The loss of compressive strength is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com