UV-cured anti-glare coating and preparation method thereof

An anti-glare and coating technology, applied in the field of coatings, can solve the problems of large water contact angle of anti-glare coating pencils, inability to effectively produce anti-glare, and inability to produce anti-glare effects, so as to improve the friction resistance of steel wool and excellent Anti-glare effect, effect conducive to mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

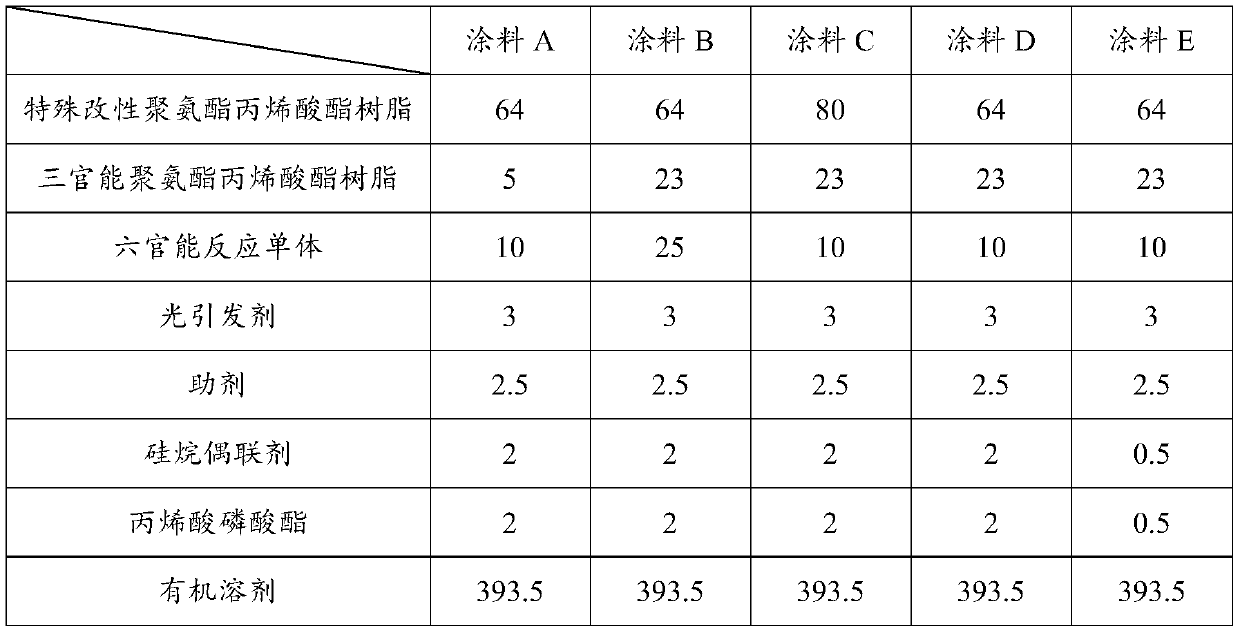

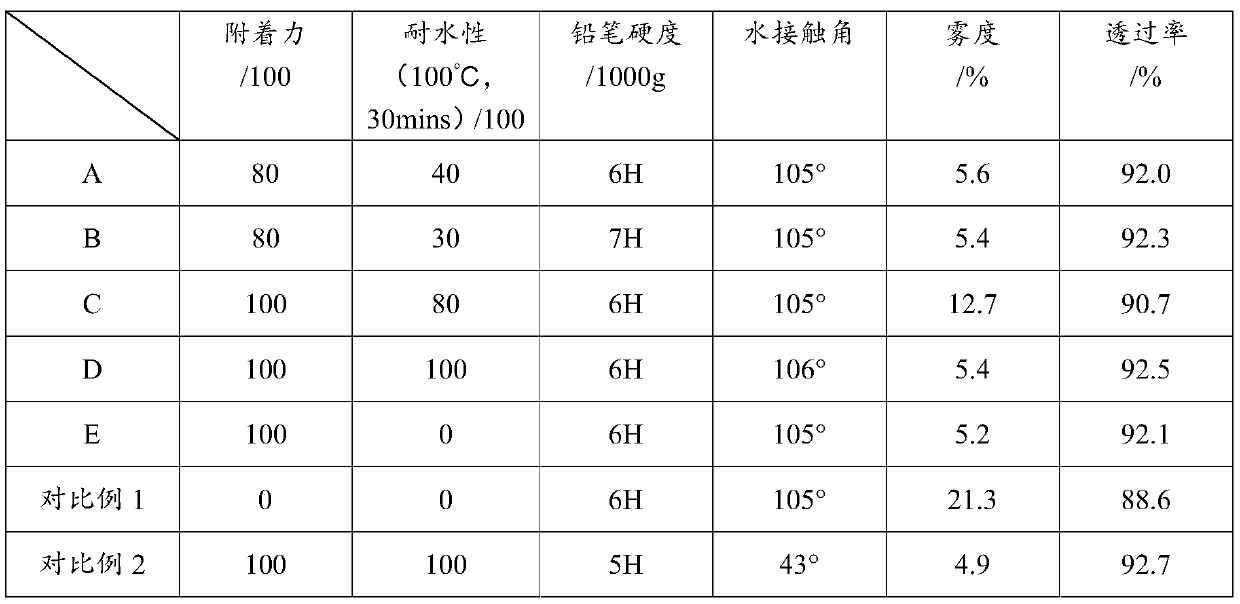

[0045] This example provides a kind of UV curable anti-glare coating, this UV curable anti-glare coating comprises the following preparation raw materials in parts by weight:

[0046] Modified urethane acrylate resin: 40-70 parts, trifunctional urethane acrylate resin: 10-30 parts, multifunctional reactive monomer: 10-20 parts, photoinitiator: 2-5 parts, auxiliary agent: 1-3 parts , Silane coupling agent: 1-2 parts, acrylate phosphate: 1-2 parts, organic solvent: 300-600 parts.

[0047] Among them, the modified polyurethane acrylate resin is Changxing Chemical DR-U011. Specifically DR-U011-5.

[0048] The polyfunctional reactive monomer is dipentaerythritol hexaacrylate.

[0049] Each monomer molecule of the reactive monomer contains six acryloyloxy groups that can participate in photochemical reactions. Therefore, after UV curing, it can also be used as a film-forming substance to effectively increase the curing rate and crosslinking density of the UV coating, improving Im...

Embodiment 2

[0055] This example provides a kind of preparation method of UV curing anti-glare coating, and the steps include:

[0056] S1: Weigh the preparation raw materials according to the proportion, and disperse the modified urethane acrylate resin, trifunctional urethane acrylate resin, multifunctional reactive monomer, photoinitiator and auxiliary agent evenly under light-shielding conditions;

[0057] S2: Add the silane coupling agent, acrylate phosphate and organic solvent into the mixture in step S1 and mix well to obtain the UV curable anti-glare coating.

[0058] In step S1, the speed of dispersion is 200-500 rpm.

Embodiment 3

[0060] This example provides the construction method of UV curable anti-glare coating, and the application substrate of the coating is clean glass or metal.

[0061] The specific construction methods are:

[0062] (1) Filter with 400-500 mesh after opening the tank;

[0063] (2) Spray the coating obtained in step (1) onto the corresponding product in a clean room. The temperature of the clean room is 18-25°C, the humidity is 50-70%, the spraying air pressure is 0.5-1MPa, and the dry film thickness is 2~5μm;

[0064] (3) Bake the product sprayed in step (2) at 60-80°C for 5-8 minutes, and then cure it with ultraviolet light. The curing energy is 800-1000mJ / cm 2 , the final sample is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com