Sphingomonas engineering bacterium as well as construction method and application thereof

A sphingomonas and engineering bacteria technology, applied in the field of sphingomonas engineering bacteria and its construction, can solve the problems of low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

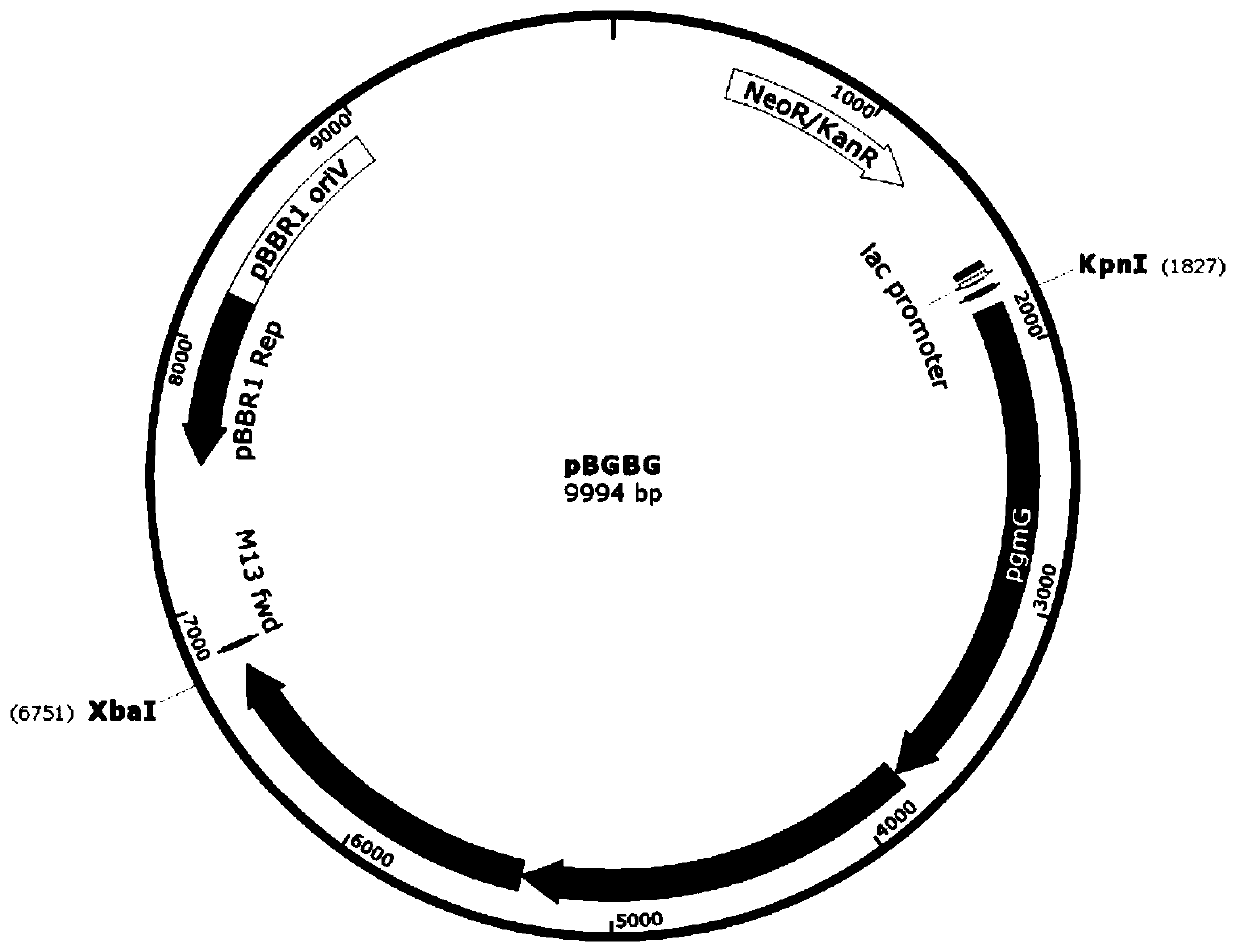

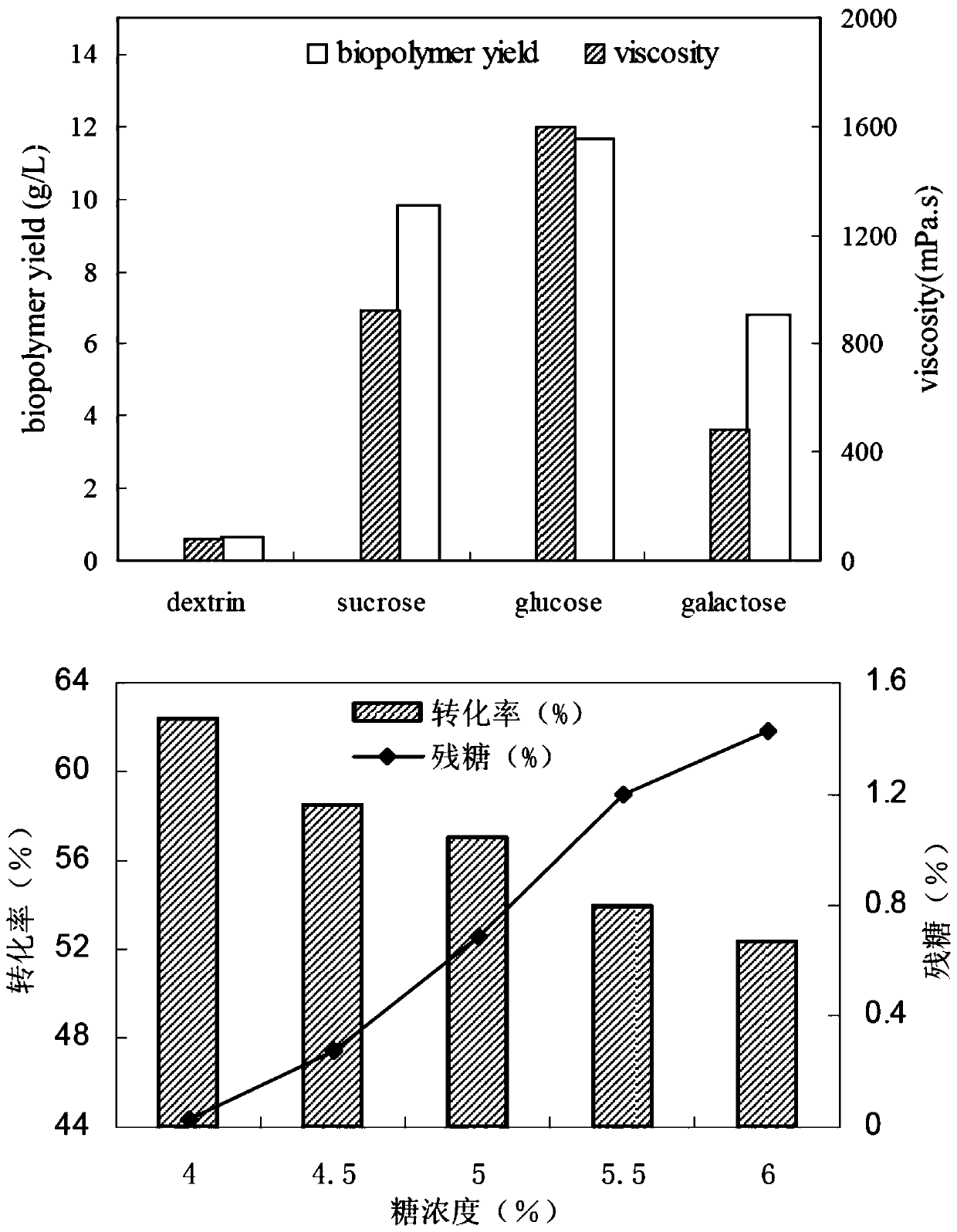

[0047] Example 1 Sanzan gum synthesis key gene high expression vector and construction of recombinant bacteria

[0048] Studies have shown that the genes pgmG, ssB and ssG are the key genes for the synthesis of sanzan glue. The total DNA of the Sphingomonas sp.T-3 strain was extracted using a genome extraction kit, and the target gene was amplified using the T-3 genome as a template, using primers pgmG1 / pgmG2, ssB1 / ssB2, and ssG1 / ssG2, respectively, using PrimeSTAR DNA polymerase (Takara Bio, Tokyo, Japan) respectively amplified the three genes pgmG, ssB and ssG (SEQ ID NO: 1-3), and purified and recovered the obtained target gene bands with a gel recovery kit to obtain target fragments. Firstly, the pgmG fragment and the pBBR1mcs-2 plasmid were simultaneously digested with restriction enzymes KpnI and EcoRI at 37° C. for 90 min. The digested fragments were purified and recovered by PCR using a kit, and the recovered products of the two were ligated overnight at 16°C with T4 ...

Embodiment 2

[0049] The construction of embodiment 2 genetic engineering strain MH-10

[0050] Pick a single colony of Sphingomonas sp.T-3 from the plate medium and inoculate it into 5ml seed medium containing chloramphenicol, culture it in a constant temperature shaker at 30°C at 200rpm for 24h, pick a single colony of E.coli s17 / pBGBG until it contains card In the LB liquid medium of namycin, cultivate it in a constant temperature shaker at 37°C at 200rpm for 8h, take 5ml of each of the two strains and centrifuge at 6000rpm for 5min to collect the bacteria, and use 10mmol / L MgSO 4 The solution was washed twice, centrifuged, and then washed with 200ul of MgSO 4 Resuspend the bacteria in the solution, mix T-3 and E.coli s17 / pBGBG according to the ratio of 2:1, then suction filter until the pore size is placed on a 0.22um filter membrane, and place the filter membrane with the bacteria facing up in the absence of On the resistant plate, cultured in a constant temperature incubator at 30°C ...

Embodiment 3

[0051] Shake flask fermentation of embodiment 3 genetic engineering strain MH-10

[0052] (1) Inoculate a single colony of the genetically engineered bacterium MH-10 into 5 ml of TPG liquid medium, and culture with shaking at 30°C for 24 hours;

[0053] (2) Inoculate the culture solution prepared in step (1) into 100 ml of seed culture medium, and shake and culture at 30° C. for 24 hours;

[0054] (3) Inoculate the seed solution prepared in step (2) into a glass shake flask containing an initial fermentation medium with an inoculum amount of 6-10%, culture at 30° C., constant pH 6.8-7.2, 200 rpm, and shake for 72 hours;

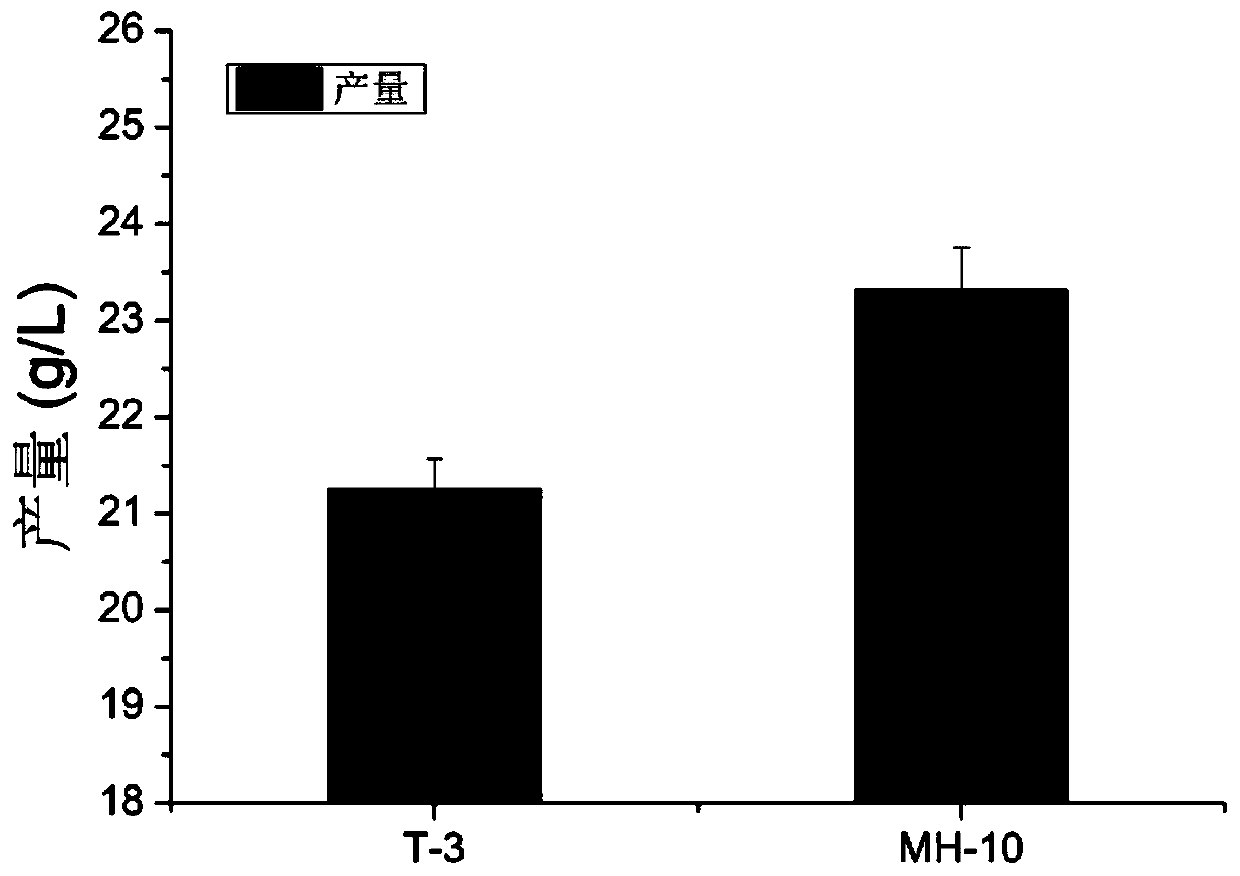

[0055] (4) Adjust the pH of the fermented liquid in step (3) to about 3.0 with dilute hydrochloric acid, dry to obtain microbial polysaccharides, weigh them, and compare the yield with the original strain, the results are as follows figure 2 shown. Compared with the original strain T-3, the production of Sanzan gum synthesized by the engineered strain MH-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com