Method for removing impurity iron in gasification slag

A gasification slag and impurity technology, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve problems such as reducing product performance and quality, hindering high-value conversion of resources, affecting product appearance and color, and achieving economic and environmental protection. Significant benefits, no waste liquid discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

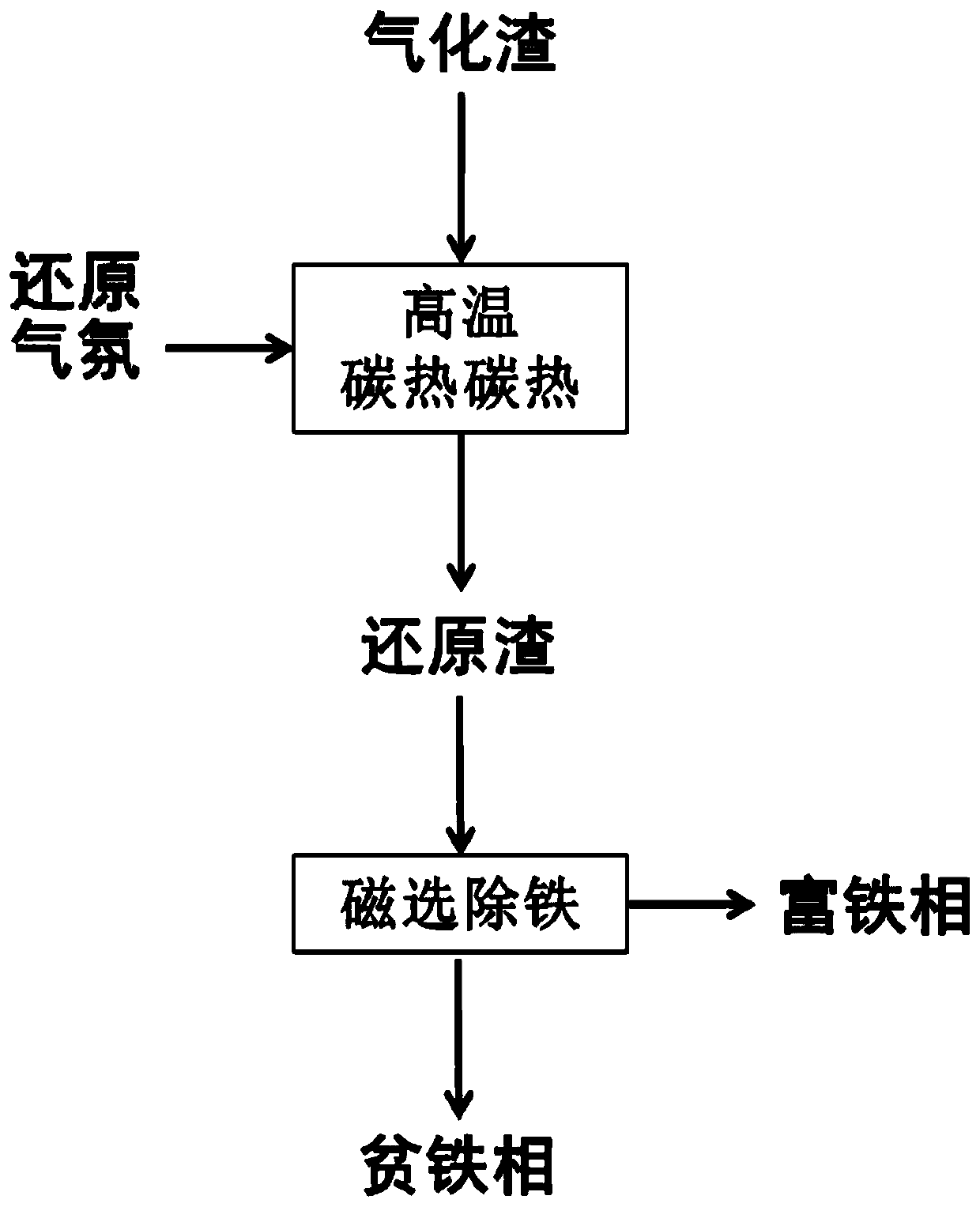

[0022] Such as figure 1 As shown, the removal method of impurity iron in gasification slag in the present embodiment comprises the following steps:

[0023] High-temperature carbothermal reduction process: put the gasification slag in a high-temperature furnace, pass in argon to ensure that it is in a reducing atmosphere, raise the temperature from room temperature to 800°C at a rate of 9°C / min, and keep it for 1 hour; further increase the temperature at 4°C / min The heating rate was raised to 1250°C in min, kept for 3 hours, and cooled to room temperature;

[0024] Magnetic separation process: Magnetic separation and iron removal are carried out under the condition of a magnetic field strength of 3000Gs;

[0025] The iron content in the iron removal slag obtained is reduced from 9% to 1.82%, the iron removal rate is as high as 80%, and the slag loss is 17%.

Embodiment 2

[0027] Such as figure 1 As shown, the removal method of impurity iron in gasification slag in the present embodiment comprises the following steps:

[0028] High-temperature carbothermal reduction process: put the gasification slag in a high-temperature furnace, pass in argon to ensure that it is in a reducing atmosphere, raise the temperature from room temperature to 650 °C at a rate of 8 °C / min, and keep it for 1 hour; further increase the temperature at 3 °C / min The heating rate was raised to 1250°C in min, kept for 2.5 hours, and cooled to room temperature;

[0029] Magnetic separation process: Magnetic separation and iron removal are carried out under the condition of a magnetic field strength of 3500Gs;

[0030] The iron content in the iron removal slag obtained is reduced from 9% to 2.33%, the iron removal rate is as high as 74%, and the slag loss is 21%.

Embodiment 3

[0032] Such as figure 1 As shown, the removal method of impurity iron in gasification slag in the present embodiment comprises the following steps:

[0033] High-temperature carbothermal reduction process: put the gasification slag in a high-temperature furnace, pass in hydrogen to ensure that it is in a reducing atmosphere, raise the temperature from room temperature to 750°C at a rate of 6°C / min, and keep it for 1.5h; further increase the temperature at 4°C / min The heating rate was raised to 1200°C in min, kept for 3 hours, and cooled to room temperature;

[0034] Magnetic separation process: Magnetic separation and iron removal are carried out under the condition of a magnetic field strength of 4000Gs;

[0035] The iron content in the iron removal slag obtained is reduced from 9% to 1.74%, the iron removal rate is as high as 81%, and the slag loss is 18%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com