Tubular pile boiler steam system

A technology for steam systems and boilers, applied in fixed tubular conduit components, combined devices, lighting and heating equipment, etc., can solve problems such as waste of heat resources, environmental pollution, etc., and achieve improved heat recovery rate, effective filtration and treatment, The effect of slowing the speed of the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

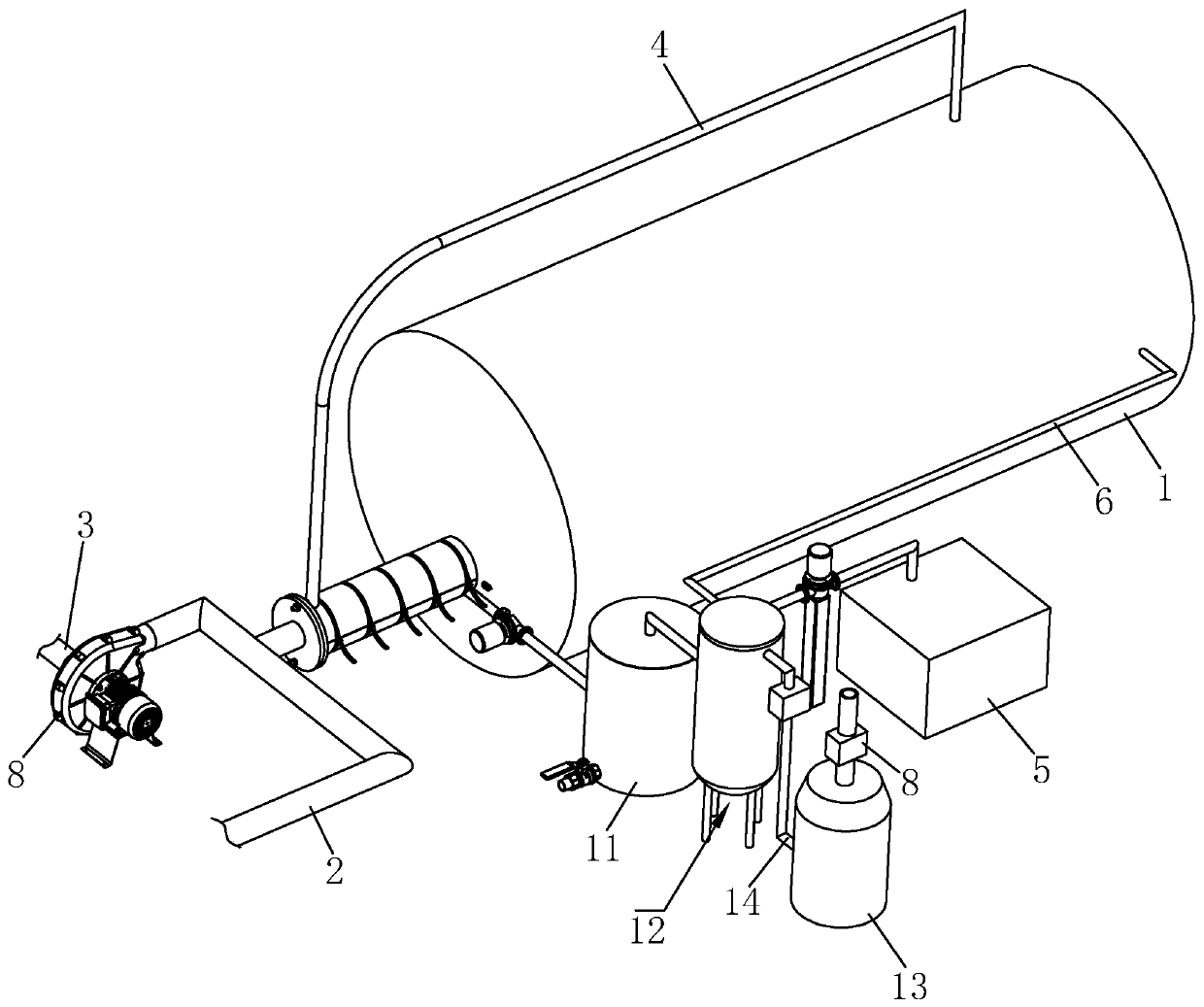

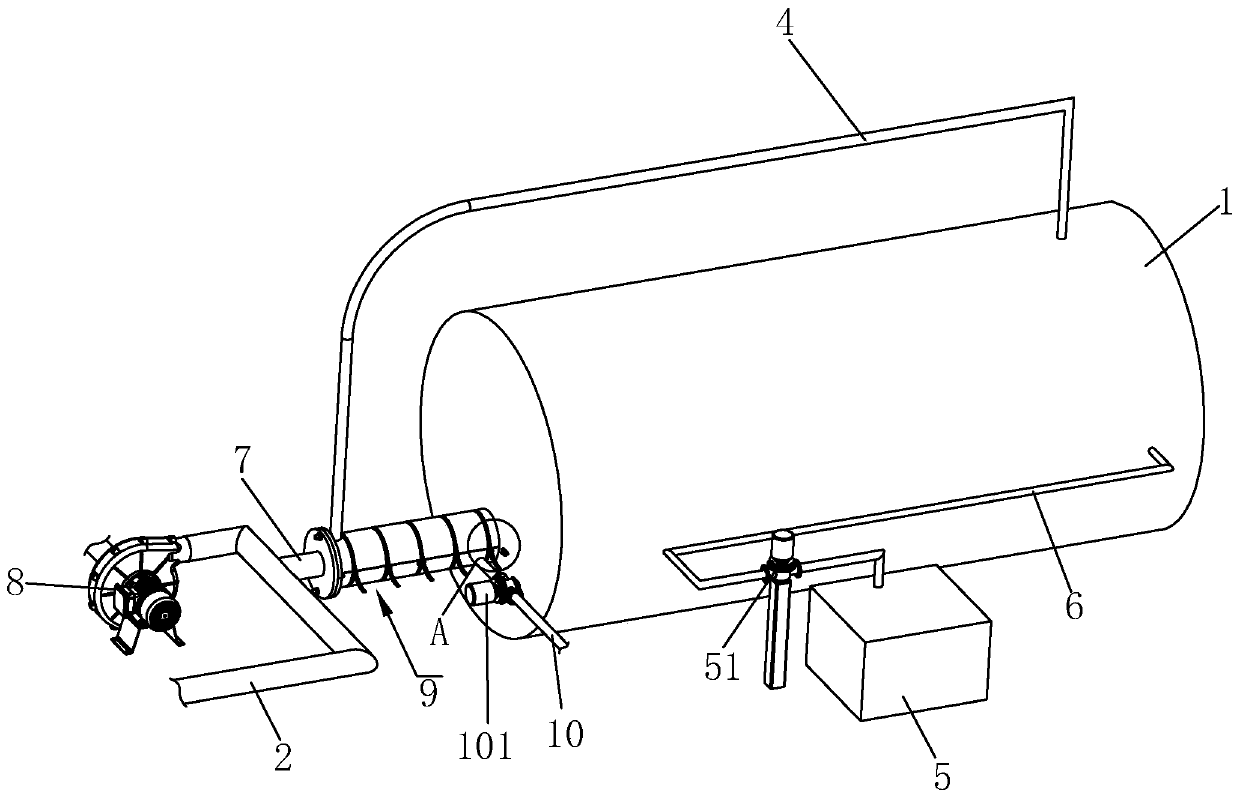

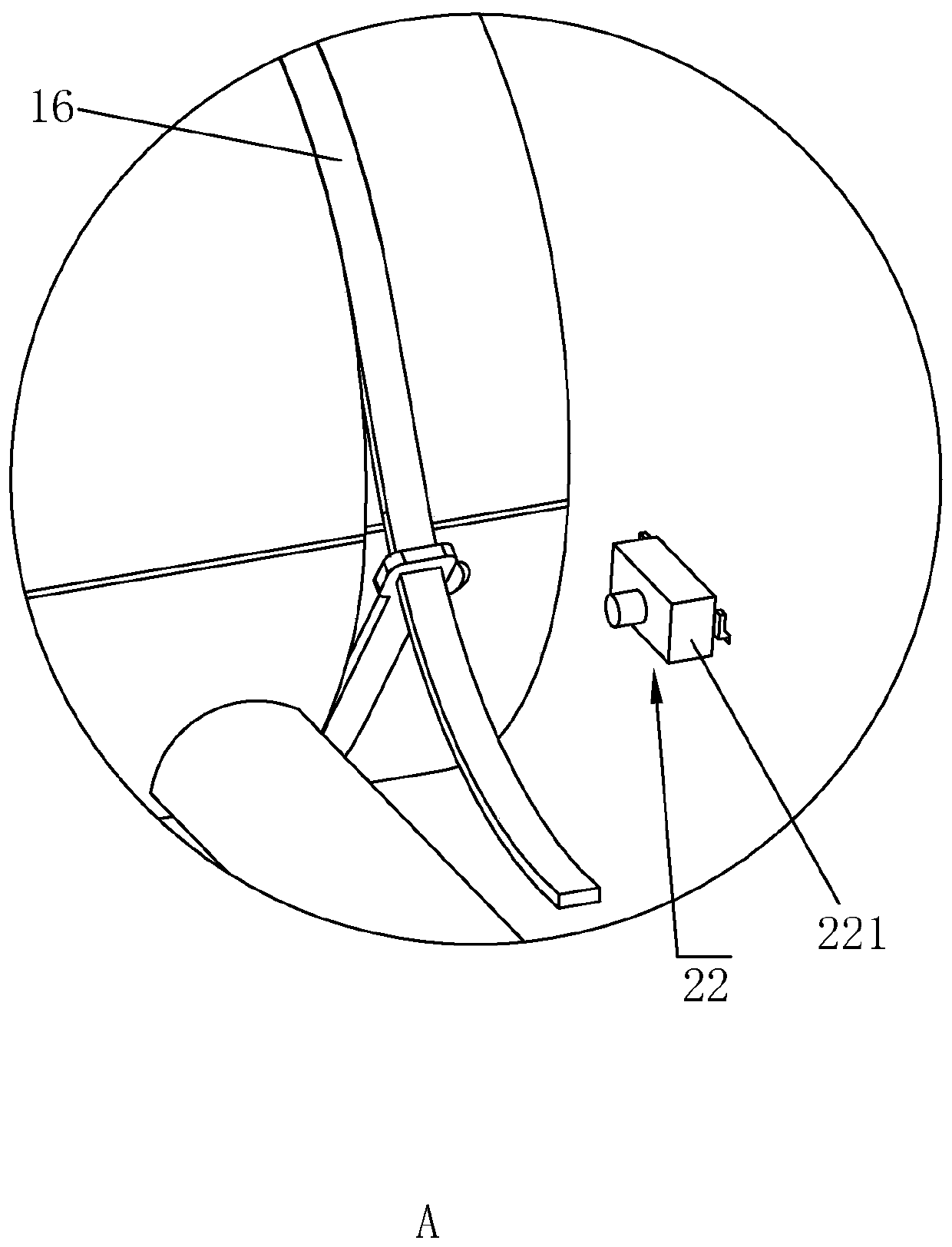

[0042] A pipe pile boiler steam system, with reference to figure 1 and figure 2 , including boiler 1, gas pipeline 2, air pipeline 3, steam pipeline, water tank 5 and two water inlet pipes 6, one end of one water inlet pipe 6 communicates with water tank 5, and the other end communicates with boiler 1, and the upper end of water inlet pipe 6 A water pump 51 is provided, a connecting pipe 7 is connected to one side of the boiler 1, the gas pipe 2 and the air pipe 3 are connected to the connecting pipe 7, the boiler 1 is connected to a smoke exhaust pipe 4, and the connecting pipe 7 is connected to a heat pipe 9 The end of the heat pipe 9 away from the boiler 1 is in communication with the exhaust pipe 4; the heat pipe 9 is provided with a windshield assembly along its length. The smoke exhaust pipe 4 is set on the connecting pipe 7 where the air and gas are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com