Underground intelligent drilling distance measurement and dustproof fixed-point sampling device and working method thereof

A fixed-point sampling and dust-proof technology, applied in sampling devices, measuring devices, measuring distances, etc., can solve the problems of drilling rig base wear, low precision, high labor intensity, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

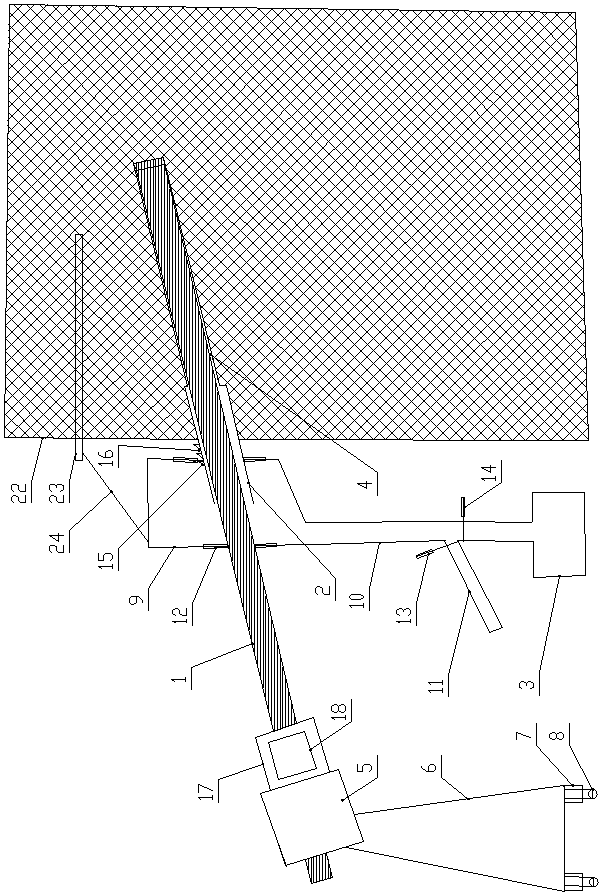

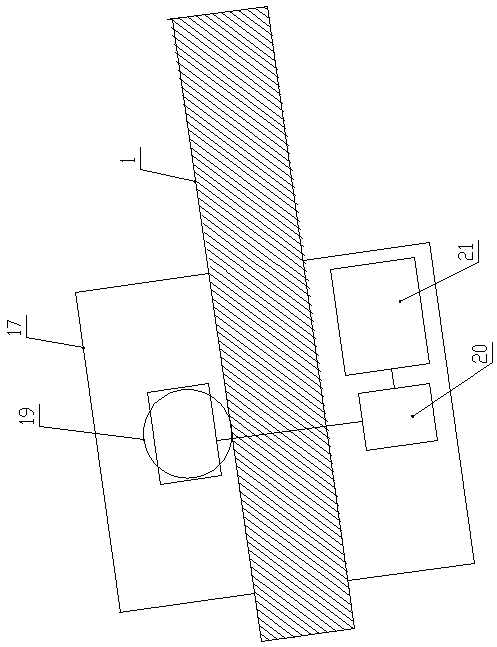

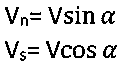

[0047] Such as figure 1 with figure 2 As shown, a downhole intelligent drilling ranging and dust-proof fixed-point sampling device includes a drilling rig, a drill pipe 1, a drilling rangefinder, a dust-proof shroud, a reserved guide pipe 2 and a cuttings dust collector 3. The reserved guide pipe 2 is fixedly installed at the opening of the drilled hole 4, and the outer end of the reserved guide pipe 2 protrudes from the drilled hole 4. The port is connected to the inlet of the cuttings dust collector 3, the drill pipe 1 is installed on the drilling rig, the drill pipe 1 passes through the cuttings dust collector 3 and extends coaxially into the reserved guide pipe 2, and the drilling range finder is fixed on the On the drilling rig, the testing part of the borehole distance meter is in contact with the outer surface of the drill pipe 1 .

[0048] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com