Composition, thermoplastic resin composition using same, and molded article thereof

A thermoplastic resin and composition technology, applied in the field of thermoplastic resin composition and its molded body, can solve the problems of transparency, insufficient strength, low molding cycle, slow crystallization speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

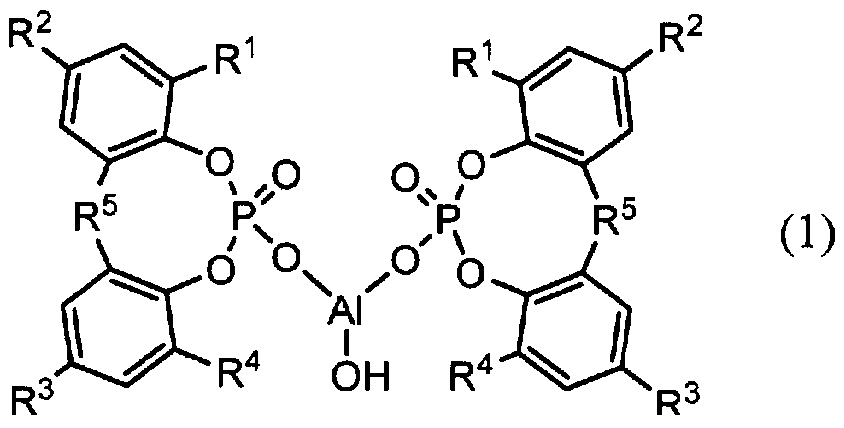

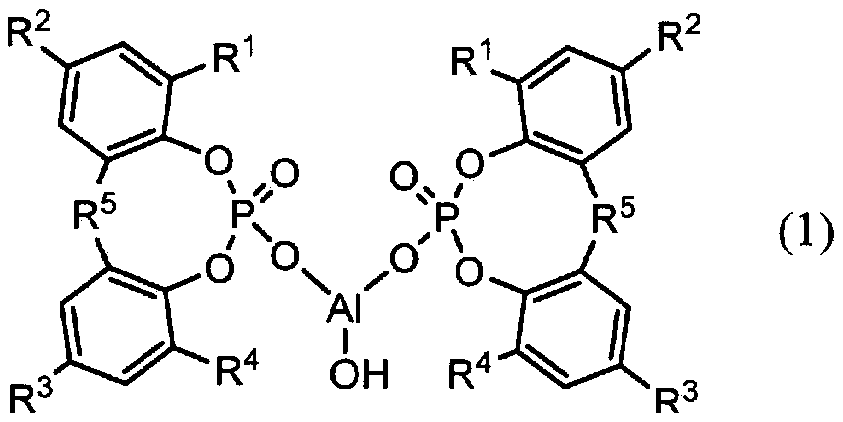

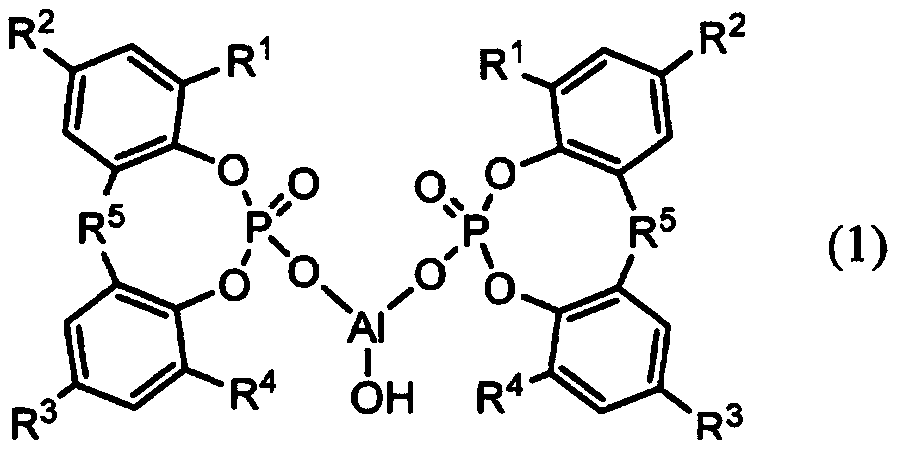

Method used

Image

Examples

Embodiment 1-1~1-6、 comparative example 1-1~1-9

[0086] A phenolic antioxidant (tetrakis[methylene-3 -(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] methane) 0.05 parts by mass, phosphorus antioxidant (tris(2,4-di-tert-butylphenyl) phosphorous acid 0.1 parts by mass of ester), 0.05 parts by mass of hydrotalcite (trade name "DHT-4A" manufactured by Kyowa Chemical Industry Co., Ltd.), and the compositions described in Tables 1 to 3 were mixed using a Henschel mixer at 1000 rpm x 1 minute Then, pelletizing was performed at an extrusion temperature of 230° C. using a twin-screw extruder. After drying the granulated pellets at 60°C for 8 hours, the flexural modulus and deflection temperature under load (HDT) were measured under the conditions described below. These results are shown in Tables 1-3, respectively. In addition, all the units of each component in a table|surface are mass parts.

Embodiment 2-1~2-2、 comparative example 2-1~2-8

[0088] A phenolic antioxidant (tetrakis[methylene-3 -(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] methane) 0.05 parts by mass, phosphorus antioxidant (tris(2,4-di-tert-butylphenyl) phosphorous acid 0.1 parts by mass of ester), 0.05 parts by mass of hydrotalcite (trade name "DHT-4A" manufactured by Kyowa Chemical Industry Co., Ltd.), and the compositions described in Table 4 and Table 5 were mixed using a Henschel mixer at 1000 rpm x 1 minute Then, pelletizing was performed at an extrusion temperature of 230° C. using a twin-screw extruder. After drying the granulated pellets at 60° C. for 8 hours, the haze was measured under the conditions described below. These results are shown in Table 4 and Table 5, respectively. In addition, all the units of each component in a table|surface are mass parts.

Embodiment 3-1~3-7、 comparative example 3-1~3-7

[0090] A phenolic antioxidant (tetrakis[methylene- 3-(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] methane) 0.05 parts by mass, phosphorus antioxidant (tris(2,4-di-tert-butylphenyl) Phosphate) 0.1 parts by mass, calcium stearate 0.05 parts by mass, crosslinking agent or peracid {2,5-dimethyl-2,5-bis(t-butylperoxy)hexane} 0.023 parts by mass , and the compositions described in Table 6 and Table 7 were mixed with a Henschel mixer at 1000 rpm for 1 minute, and then pelletized at an extrusion temperature of 230° C. using a twin-screw extruder. After drying the granulated pellets at 60°C for 8 hours, the flexural modulus and deflection temperature under load (HDT) were measured under the conditions described below. In addition, the melt flow rate of the granulated pellets was 40 g / 10 minutes. These results are shown in Table 6 and Table 7, respectively. In addition, all the units of each component in a table|surface are mass parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com