A kind of regeneration method of alumina column

An alumina column and alumina technology, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve problems such as environmental pollution, lack of alumina column regeneration methods, cost increase, etc., to restore chromatography ability, Recovery of chromatographic ability and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1. Add sodium hypochlorite solution with a mass fraction of 40% to the waste alumina column, the sodium hypochlorite solution flows through the alumina column at a flow rate of 150 L / h, and drips dry the alumina column. Wherein, the consumption of the sodium hypochlorite solution is 5 times the weight of the alumina.

[0027] Step 2, the purified water is passed through the drip-dried alumina column obtained in step 1, until the pH value of the outflowing liquid is 7, the alumina column is dripped dry, the flow rate is 100L / h, and the consumption of purified water is 100% of the alumina weight. 5 times.

[0028] Step 3, passing 97% ethanol by mass through the drip-dried alumina column obtained in step 2, until the ethanol concentration of the inflow and outflow is the same, drip-dry the alumina column to obtain a regenerated alumina column, wherein the flow rate is 100L / h, the amount of ethanol used is 5 times the weight of alumina.

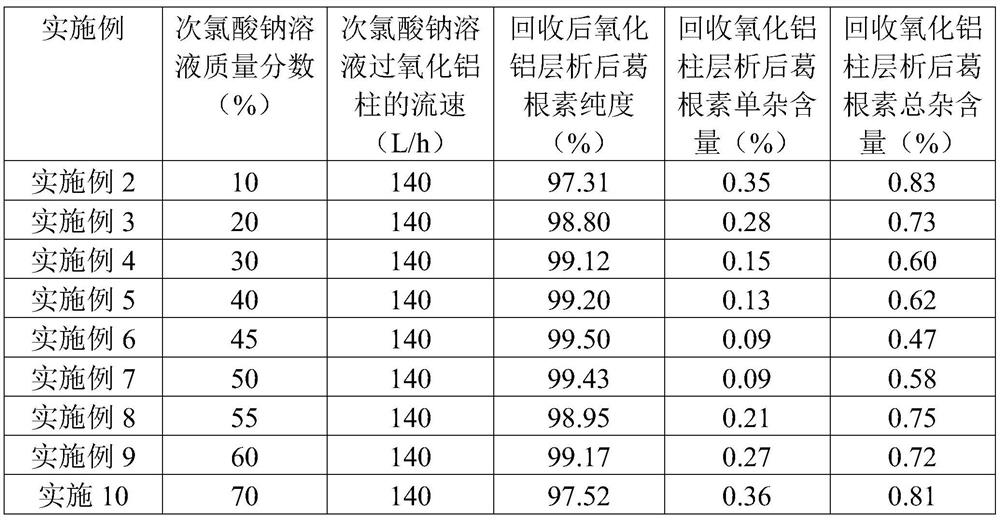

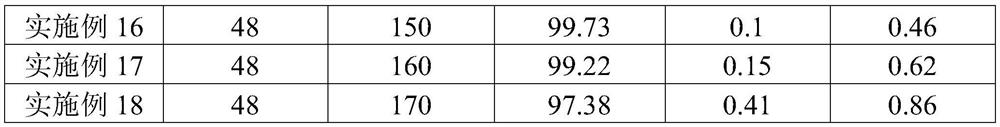

Embodiment 2-10

[0030] The process of purification and recovery of the waste alumina column in Examples 2-10 is the same as that in Example 1, except that it is different from the concentration of sodium hypochlorite and the flow rate of sodium hypochlorite flowing through the alumina column.

experiment example

[0032] Chromatographic Capability Test of Regenerated Alumina Column and New Alumina Column

[0033] At present, the technical method for extracting puerarin from pueraria is generally to first clean the puerarin, dry it, then pulverize it into puerarin powder, and then obtain the crude puerarin through ultrasonic-assisted extraction, water extraction or alcohol extraction. Usually, the process of ultrasonic-assisted extraction is: pueraria root powder → ultrasonic extraction → filtration → concentration under reduced pressure → column passing → washing → alcohol washing → concentration under reduced pressure → vacuum drying → crude puerarin. Usually the process of water extraction method is: Pueraria lobata → water extraction → filtration to obtain filtrate and filter residue → sodium hydroxide solution to extract the residue → filtration to obtain filtrate → two filtrates combined → reduced pressure concentration → pH value adjustment → centrifugal separation → The filtrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com