Preparation method of ruthenium@ruthenium dioxide core-shell nanospheres containing tensile strain for acidic oxygen production electrocatalyst

An electrocatalyst, tensile strain technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., to achieve the effects of easy control, convenient operation, and increased intrinsic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

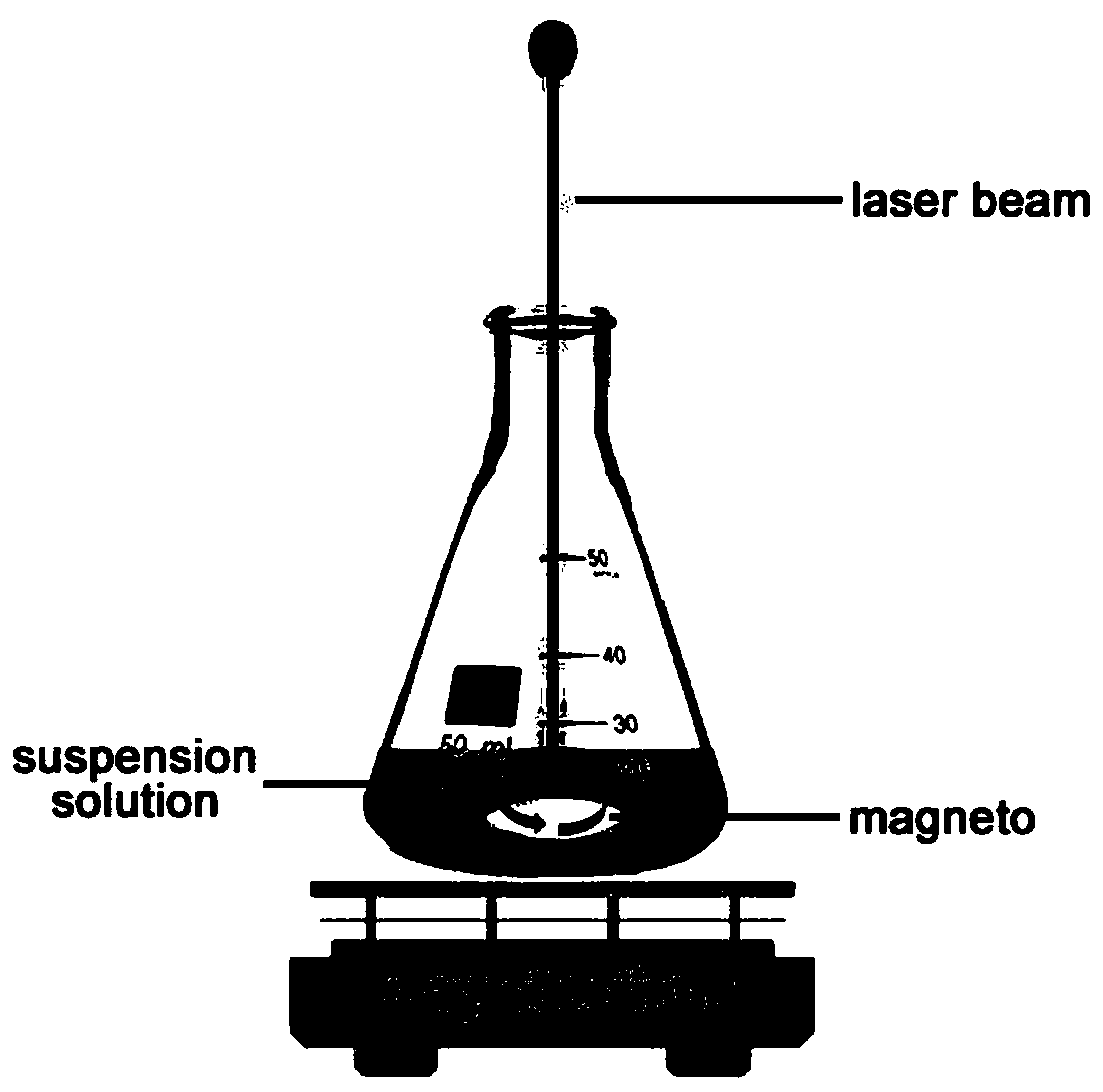

[0027] (1) Place commercial ruthenium dioxide powder in ultrapure water and ultrasonically disperse it to a suspension without precipitation at a concentration of 1.0 mg / mL;

[0028] (2) With the suspension prepared in step (1), keep stirring at room temperature, the stirring speed is 400 rpm, irradiate with nanosecond parallel pulse laser, and irradiate with nanosecond parallel pulse laser for 20min, and the energy of the laser is 518mJ , to obtain a black solution;

[0029] (3) Place the black solution obtained in step (2) in a refrigerator and freeze it into a solid at -4°C, then place the frozen solid in a lyophilizer, and freeze-dry it at -50°C and 50Pa to obtain strain-containing Ru@RuO2 core-shell nanospheres.

[0030] Schematic diagram of the process device for preparing strained ruthenium@ruthenium dioxide core-shell nanospheres by nanosecond laser irradiation figure 1 shown, loaded with RuO 2 The container of the aqueous dispersion is placed on a magnetic stirrer ...

Embodiment 2

[0035] (1) Place commercial ruthenium dioxide powder in ultrapure water and ultrasonically disperse at a concentration of 0.5 mg / mL to a suspension without precipitation.

[0036] (2) With the suspension prepared in step (1), keep stirring at room temperature, the stirring speed is 500 rpm, irradiate with nanosecond parallel pulse laser, and irradiate with nanosecond parallel pulse laser for 60min, and the energy of the laser is 185mJ , to obtain a black solution;

[0037] (3) Place the black solution obtained in step (2) in a refrigerator to freeze to a solid at -20°C, then place the frozen solid in a lyophilizer, and freeze-dry at -10°C and 20Pa to obtain strain-containing Ru@RuO2 core-shell nanospheres.

Embodiment 3

[0039] (1) Place commercial ruthenium dioxide powder in ultrapure water and ultrasonically disperse at a concentration of 0.5 mg / mL to a suspension without precipitation.

[0040] (2) With the suspension prepared in step (1), keep stirring at room temperature, the stirring speed is 300 rpm, irradiate with nanosecond parallel pulse laser, irradiate with nanosecond parallel pulse laser for 10min, and the energy of the laser is 409mJ , to obtain a black solution;

[0041] (3) Place the black solution obtained in step (2) in a refrigerator to freeze to a solid at -10°C, then place the frozen solid in a freeze dryer, and freeze-dry at -20°C and 40Pa to obtain strain-containing Ru@RuO2 core-shell nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com