Preparation method of hydrodesulfurization catalyst

A hydrodesulfurization and catalyst technology, which is applied in the field of fuel oil hydrodesulfurization, can solve the problems of less preparation methods of new hydrodesulfurization catalytic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

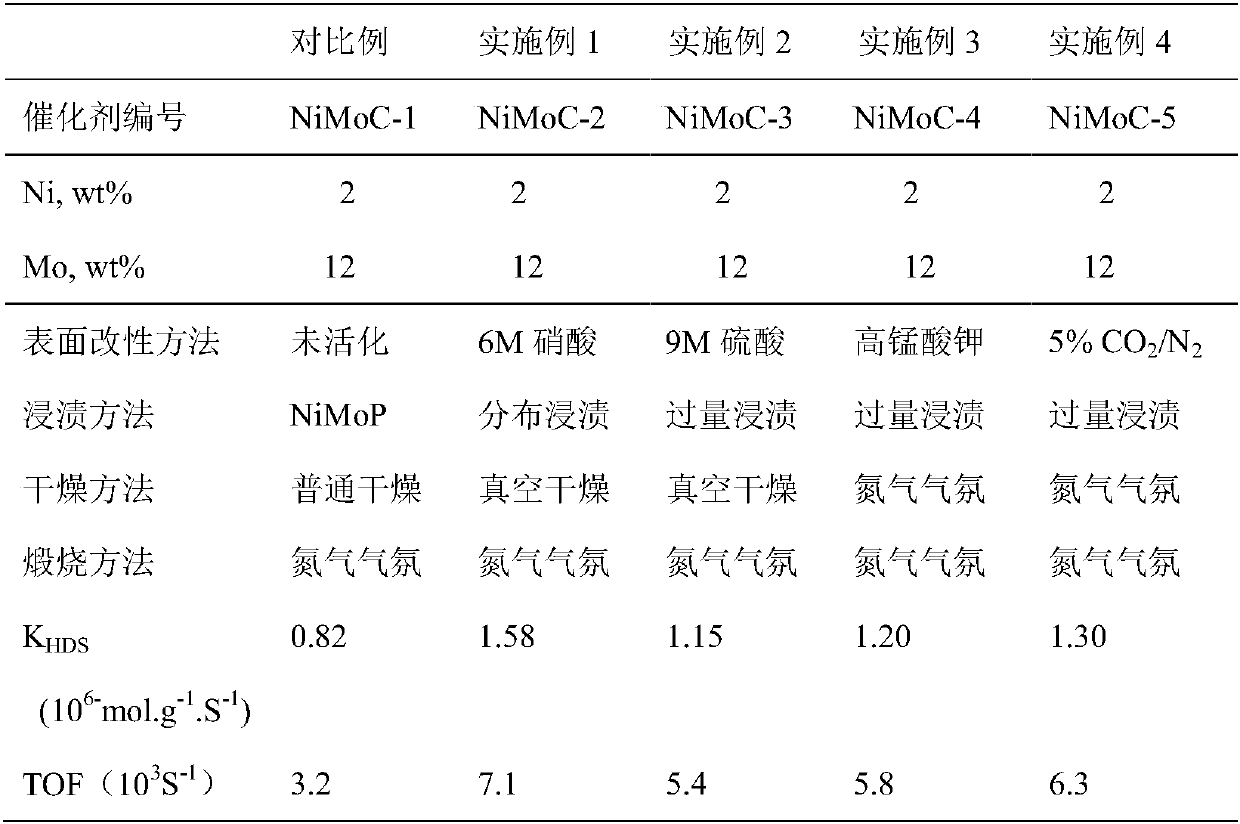

Embodiment 1

[0031] Preparation of NiMo / C-2 Catalyst

[0032] Measure 50ml of 6M dilute nitric acid solution, put it in a 250ml beaker, weigh 20g of 10-20 mesh coal-based porous carbon, soak the porous carbon in dilute nitric acid solution, ultrasonically treat for 10 minutes, replace the air bubbles, and continue soaking for 2 hours Take it out, wash until the pH of the washing solution is 7, and dry.

[0033] Put 10 g of the surface-modified coal-based porous carbon into a 100 ml beaker, and add 10 ml of ammonium molybdate solution with a Mo mass content of 12%. Sonicate for 30 minutes and let stand for 2 hours. Transfer the above carbon material and impregnating solution to a 250ml rotary evaporator, heat to 85°C and evaporate the impregnating solution to dryness. Pour into another dry beaker and let it stand for 12h. Bake in a vacuum oven at 80°C for 12 hours and take it out.

[0034] Put the dried carbon material into a tube furnace, raise it from room temperature to 500 °C at 3 °...

Embodiment 2

[0038] Preparation of NiMo / C-3 Catalyst

[0039] Measure 50ml of 9M dilute sulfuric acid solution, put it in a 250ml beaker, weigh 20g of 10-20 mesh coal-based porous carbon and soak it in the solution, and ultrasonically treat it for 10 minutes to replace the air bubbles. Take it out after continuing to soak for 6 hours, and wash until the washing solution is pH=7.

[0040] 10 g of activated coal-based porous carbon was put into a 100 ml beaker, and 10 ml of NiMoP solution with a mass content of Mo of 12% and a mass content of Ni of 2% was added. Sonicate for 30 minutes and let stand for 2 hours. Transfer the above carbon material and impregnating solution to a 250ml rotary evaporator, heat to 85°C and evaporate the impregnating solution to dryness. Pour into another dry beaker and let it stand for 12h. Bake in a vacuum oven at 80°C for 12 hours and take it out.

[0041] Put the dried carbon material into a tube furnace, raise it from room temperature to 500 °C at 3 °C / mi...

Embodiment 3

[0043] Preparation of NiMo / C-4 Catalyst

[0044] Measure 10g of potassium permanganate into 100ml of deionized water, heat to dissolve, and then put the solution in a 250ml beaker. Weigh 20 g of 10-20 mesh coal-based porous carbon and soak it in the solution, ultrasonically treat it for 10 minutes to replace the air bubbles, continue soaking for 12 hours, take it out, and wash until the pH of the washing solution is 7.

[0045] Basic nickel carbonate and ammonium molybdate were dissolved in ammonia water to prepare a NiMo ammonia solution with a mass content of Mo of 2.4% and a mass content of Ni of 0.4%. Take out 50ml of NiMo ammonia solution, and put 10g of activated coal-based porous carbon into a 100ml beaker, soak the porous carbon by excessive impregnation method, ultrasonic treatment for 30 minutes, and let it stand for 2h. Then transfer the above-mentioned carbon material and impregnating solution to a 250ml rotary evaporator, heat to 85°C and evaporate the impregnati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com