Preparation method for high-activity hydrodesulfurization catalyst

A hydrodesulfurization and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effect of improving intrinsic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of a high-activity hydrodesulfurization catalyst, the method uses carbon-based materials as a carrier, and the carbon-based materials are surface-modified; Hydrodesulfurization precursor solution, the modified carbon-based material is impregnated in the precursor solution, the active component is impregnated on the surface of the carrier, and then dried and calcined to obtain a carbon-based material containing NiMo or CoMo or NiMo active component Hydrodesulfurization catalyst.

[0029] The carbon-based material includes activated carbon, activated carbon fiber, carbon nanofiber, carbon nanotube, graphene nanoribbon, and mesoporous carbon.

[0030] The surface modification method of carbon-based materials is oxidation treatment, including acid oxidation, oxidizing gas activation, and potassium permanganate oxidation.

[0031] The acid oxidation includes inorganic acid and organic acid oxidation.

[0032] Inorganic acids for acid oxidation include ...

Embodiment 1

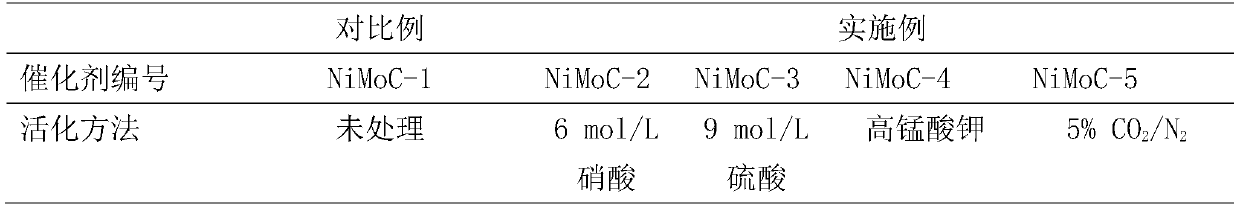

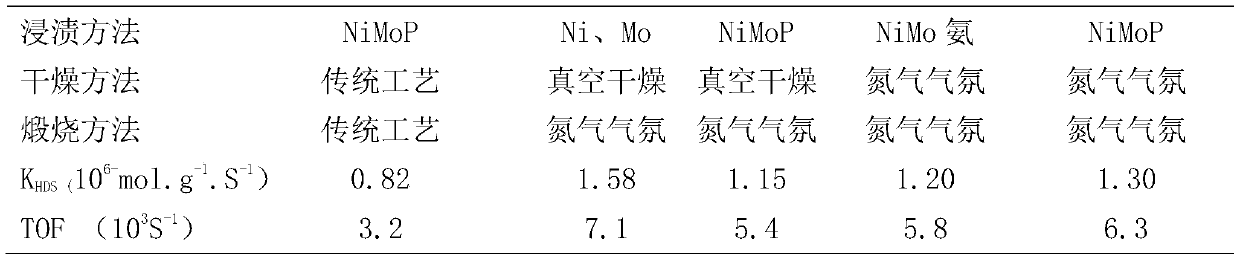

[0052] Example 1: Preparation of traditional NiMo / C catalyst, marked as comparative example NiMo / C-1.

[0053] Put 10g, 10-20 mesh coal-based porous carbon into a 100ml beaker, add 10ml NiMoP solution containing 12wt%Mo, 3wt%Ni, 0.5wt%P prepared in advance. Sonicate for 30 minutes and let stand. Transfer the above carbon material and impregnating solution to a 250ml rotary evaporator, heat to 85°C and evaporate the impregnating solution to dryness. Pour into another dry beaker and let stand overnight. Bake at 120°C for 6 hours in an ordinary drying oven and take it out.

[0054] Catalyst precursor calcination was carried out in a tube furnace. The tube furnace has an inner diameter of 60mm and a length of 1000mm. The diameter of the quartz tube in the tube furnace is 55mm, the length is about 1400mm, and the constant temperature section is 400mm. Put the dried NiMo / C material into a quartz boat with a length of 100 mm and a width of 30 mm. Push the above-mentioned quartz...

Embodiment 2

[0055] Example 2: Preparation of NiMo / C-2 catalyst, the precursor solution in this example is a water-soluble solution of single metal Ni and Mo.

[0056] Measure 50ml of 6M dilute nitric acid solution (mix concentrated nitric acid and deionized water at a ratio of 1:1), and place it in a 250ml beaker. Weigh 20g, 10-20 mesh coal-based porous carbon. The porous carbon was soaked in the solution and treated with ultrasound for 10 minutes to replace the air bubbles. Take it out after continuing to soak for 2 hours, and wash until the washing solution is PH=7.

[0057] Put 10 g of activated coal-based porous carbon into a 100 ml beaker, and add 10 ml of 12 wt % ammonium molybdate solution prepared in advance. Sonicate for 30 minutes and let stand. Transfer the above carbon material and impregnating solution to a 250ml rotary evaporator, heat to 85°C and evaporate the impregnating solution to dryness. Pour into another dry beaker and let stand overnight. Bake in a vacuum oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com