Light path light split unit and coaxial wire feed cladding head thereof

A spectroscopic unit and coaxial wire feeding technology, which is applied in the direction of optical components, optics, and condenser mirrors, can solve problems such as cladding defects, optical Louis divergence, and complex structures, so as to reduce energy loss, save water cooling systems, and improve energy distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

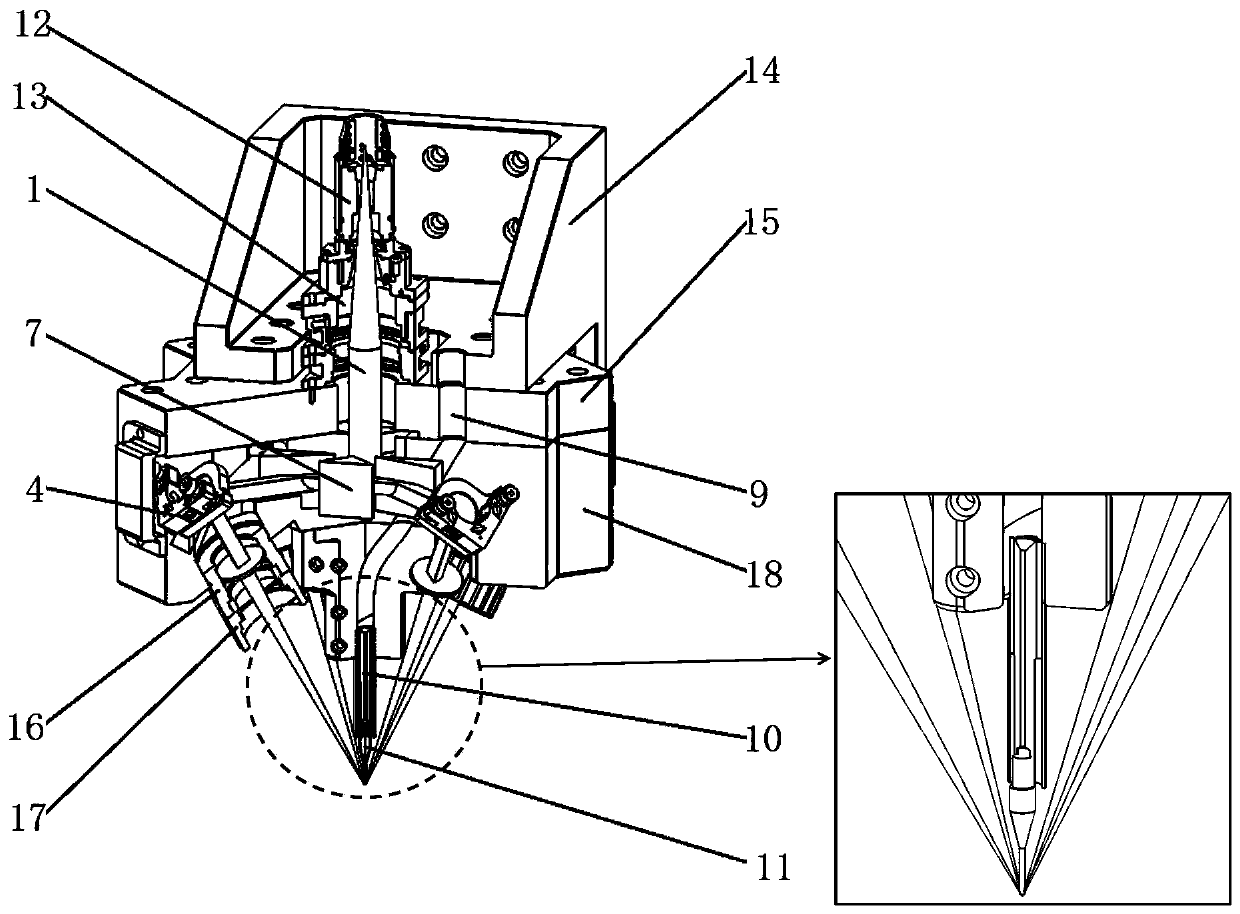

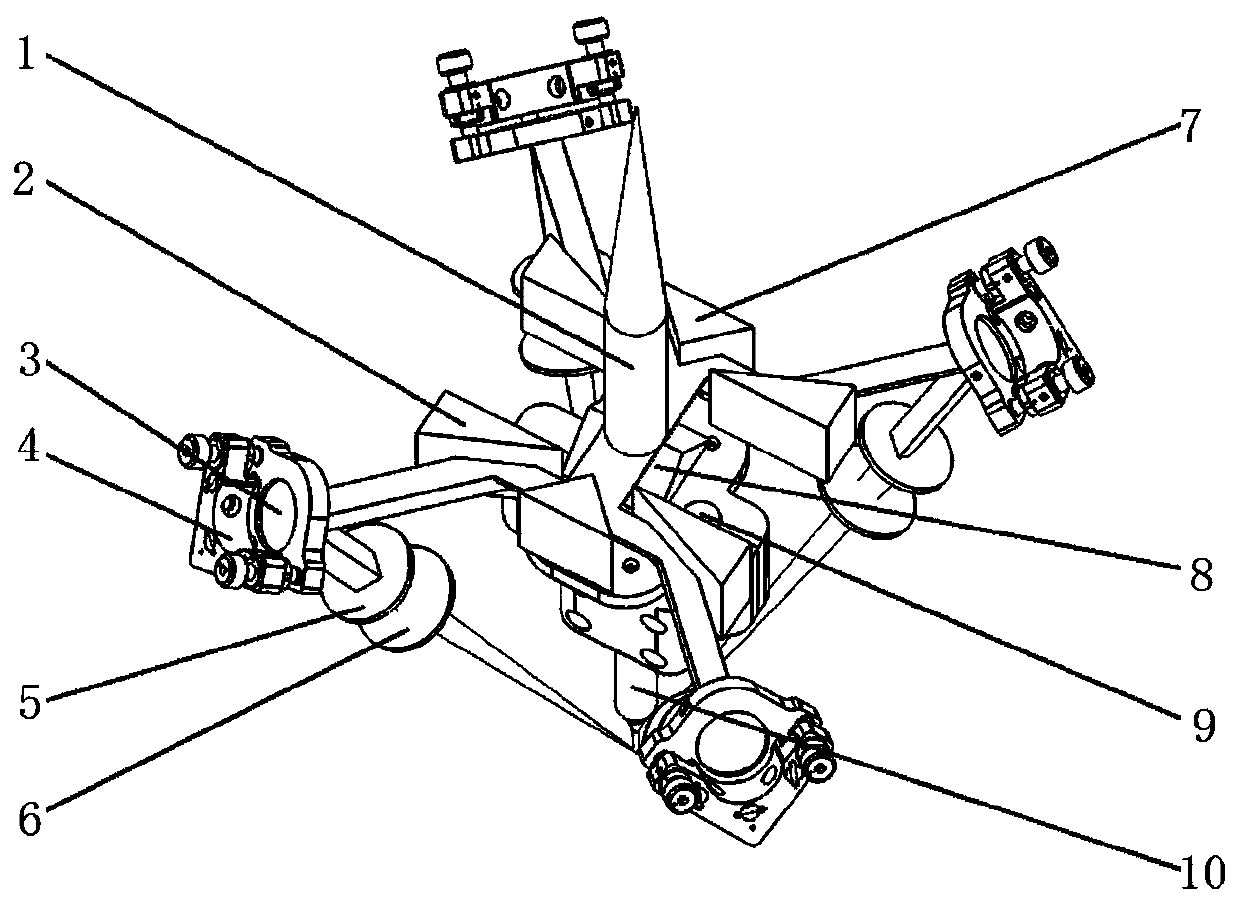

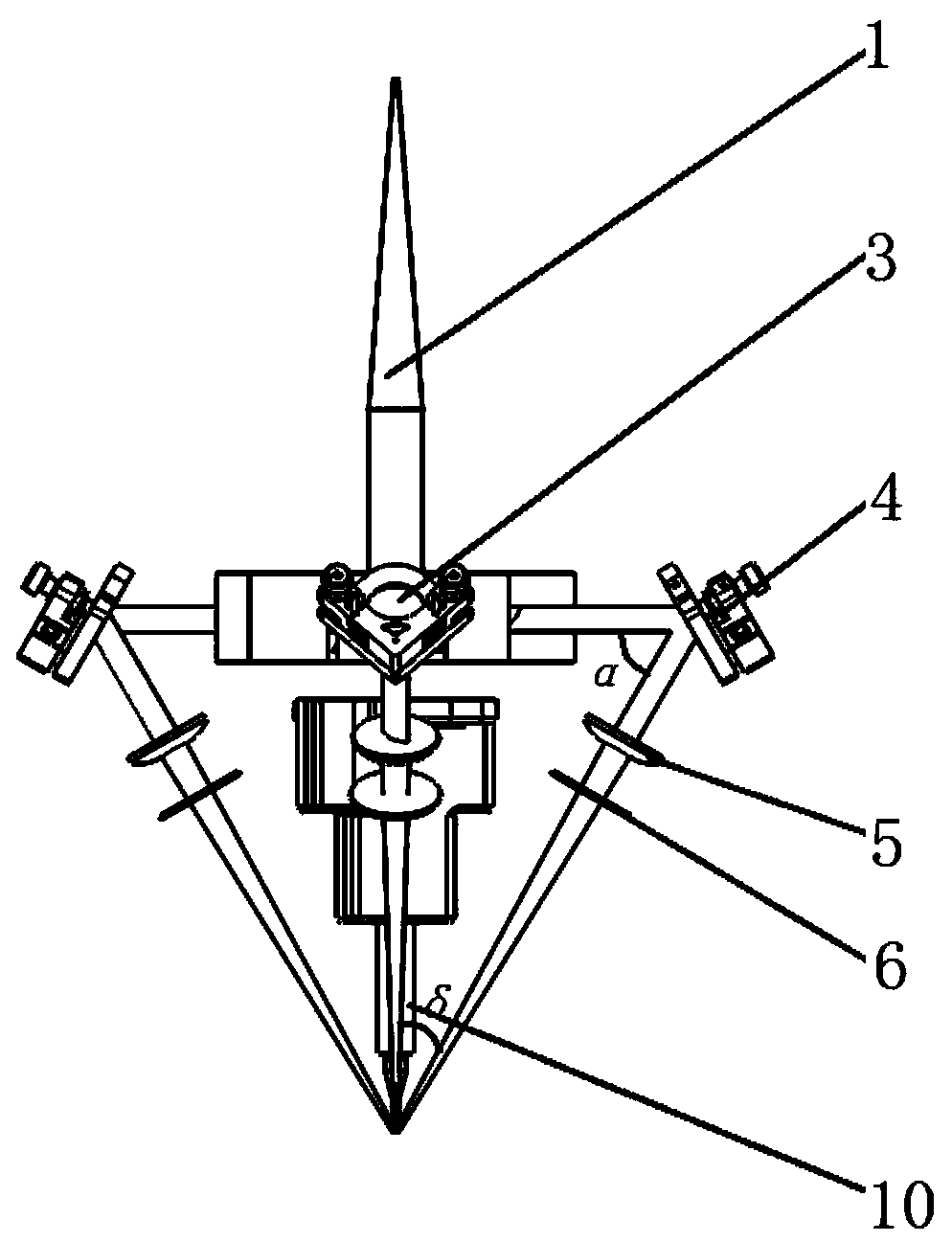

[0036] Such as figure 1 As shown, the present invention provides a coaxial wire feeding cladding head, including a connecting bracket 14, a cover 15, and a cladding head mirror cavity 18, and an optical path beam splitting unit and a wire feeding tube 10 are arranged in the cladding head mirror cavity 18, A light source collimation module 13 is arranged on the cover 15, and the wire feeding tube 10 is arranged coaxially with the collimated laser beam 1. The wire feeder 11 , the wire passes through the wire feeder 10 and the wire feeder 11 in sequence, and the adjustable mirror 3 can adjust the beam splitting to focus on the wire protruding from the wire feeder 11 .

[0037] Wherein, the collimated laser beam 1 is made of a laser as a light source, and after being collimated by the light source collimating module 13, a parallel beam is generated, and the energy distribution of the beam is uniform, and it is a flat-top distributed circular spot; the connecting bracket 14 is used...

Embodiment 2

[0050] This embodiment provides an optical path spectroscopic unit. On the basis of Embodiment 1, the spectroscopic reflector of this embodiment is a triangular pyramid, the incident laser beam is incident on the apex of the spectroscopic reflector, and the triangular pyramid can collimate the laser beam Evenly divided into three one-third light beams and the one-third light beams are located on the same plane, and the one-third light beams are irradiated to the adjustable reflector.

Embodiment 3

[0052] This embodiment provides an optical path spectroscopic unit. On the basis of Embodiment 1, the spectroscopic reflector of this embodiment is a quadrangular pyramid, and the incident laser beam is incident on the apex of the spectroscopic reflector. The quadrangular pyramid can collimate the laser beam Evenly divided into four quarter beams and the quarter beams are located on the same plane, and the quarter beams are irradiated to the adjustable reflector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com