Sub-aperture central liquid supply optical surface serial machining process and tool

An optical surface and processing tool technology, applied in optical surface grinders, manufacturing tools, grinding tools, etc., can solve the problems of affecting the quality of optical imaging, lack of effective control of surface damage suppression ability, energy loss, etc., to improve processing accuracy and polishing. Efficiency, reduced setup time, improved machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the following embodiments do not limit the present invention by any means.

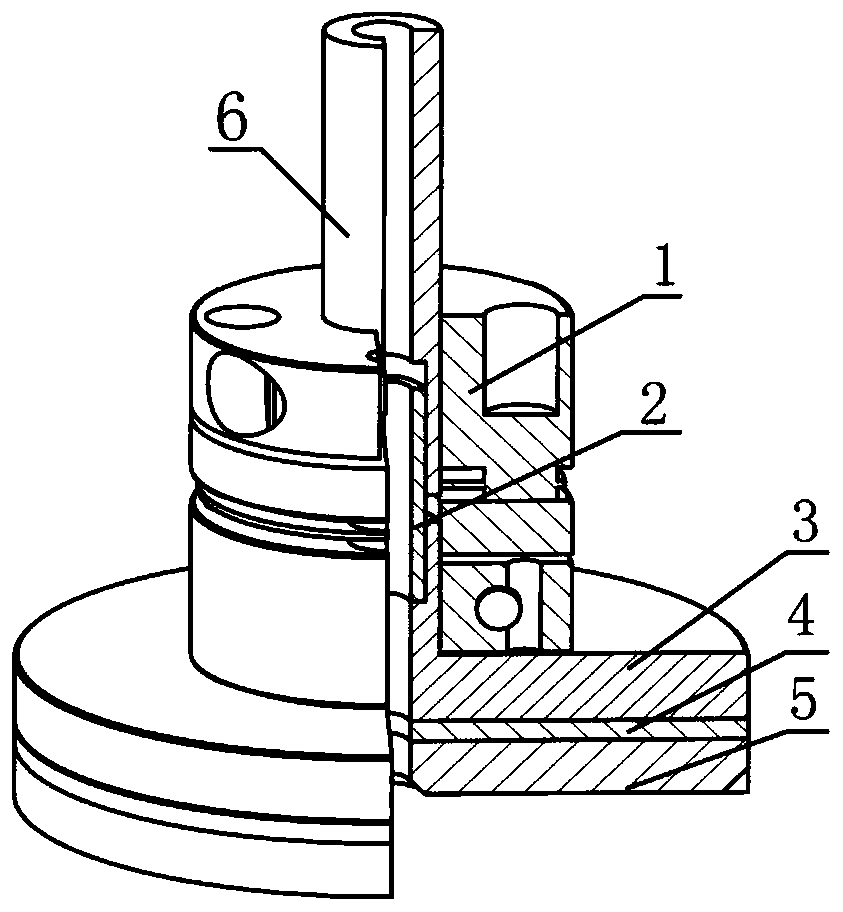

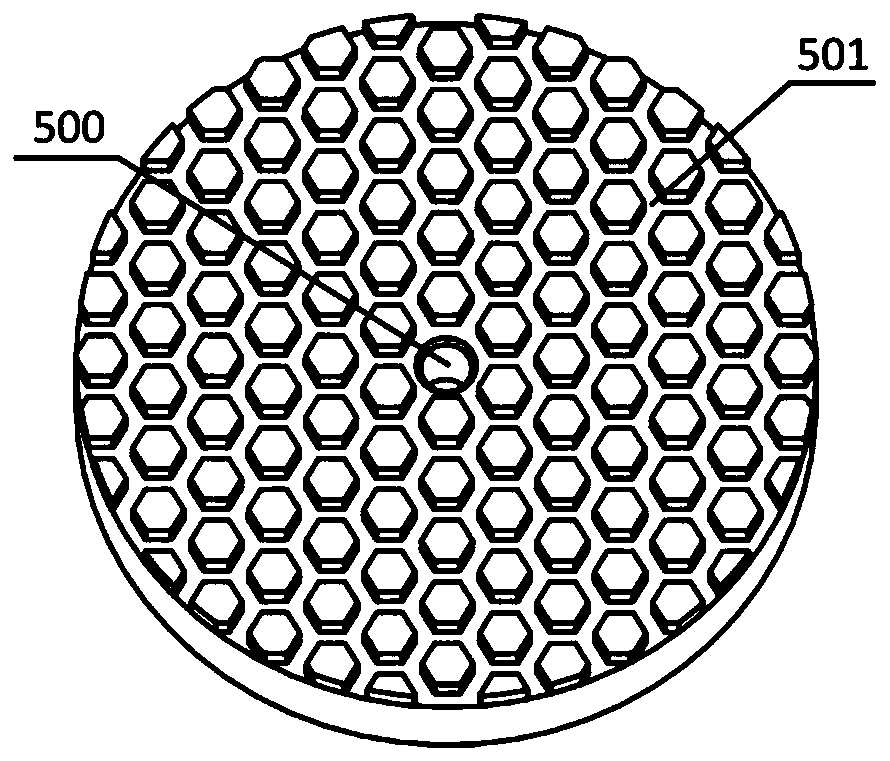

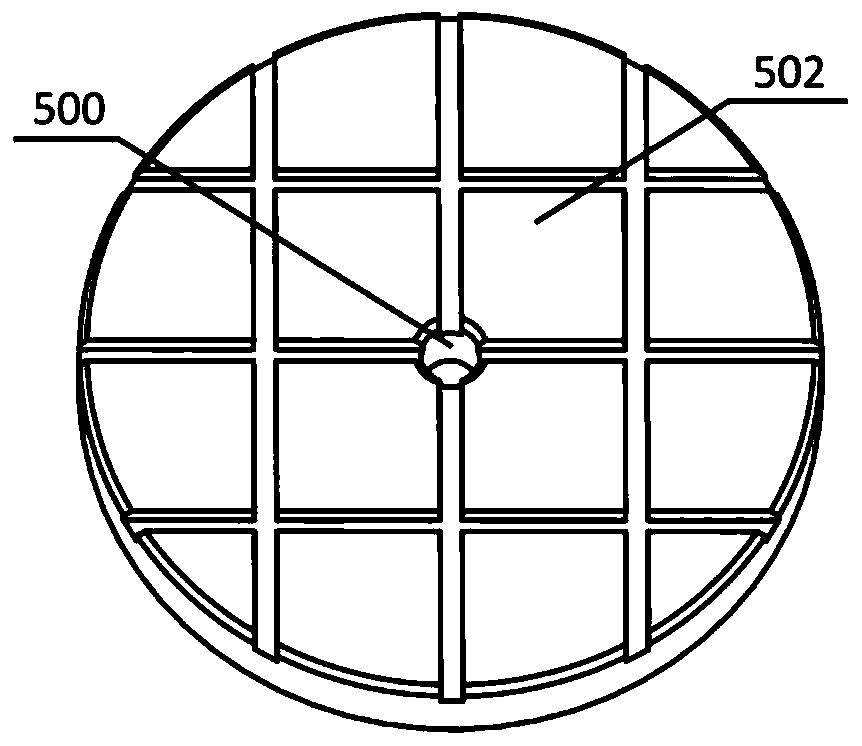

[0033] like figure 1 As shown, a sub-aperture center liquid supply optical surface processing tool proposed by the present invention includes an elastic coupling 1, a polishing disc 3 and a polishing pad 5. One end of the polishing disc 3 is a connecting shaft segment, and the polishing disc 3 The other end of the polishing disk 3 is the disk surface, the size of the polishing disk 3 is between 1 / 5 and 1 / 10 of the size of the optical element to be processed, and the diameter of the polishing disk 3 can range from 10 to 100 mm; one end of the flexible coupling 1 A rotating shaft 6 is connected, the other end of the flexible coupling 1 is connected to the polishing disc 3, and the disc surface of the polishing disc 3 is bonded to the polishing pad 5 through the elastic b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com