Slurry separation system

A mud separation and mud technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of natural sinking, affecting the construction progress and construction site environment, mud Pond occupation of construction site and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

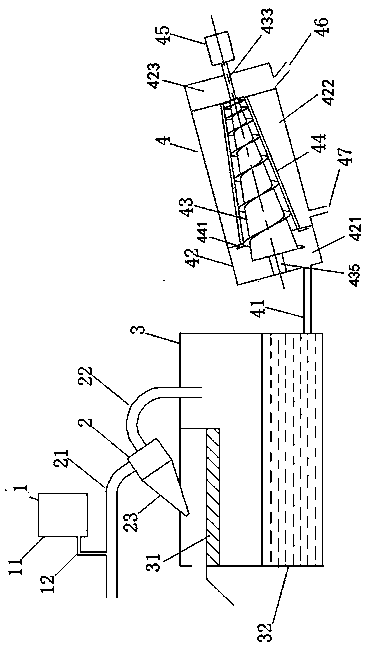

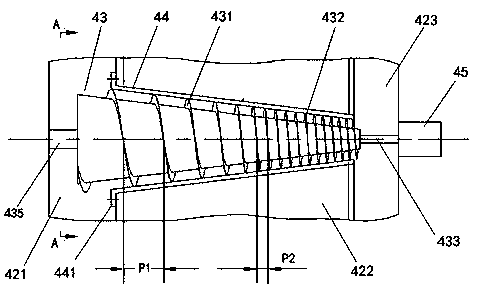

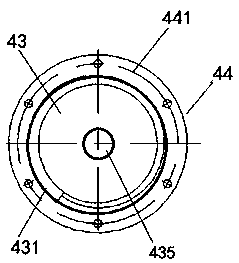

[0016] The mud separation system of the present invention will be further described below in conjunction with the accompanying drawings and examples:

[0017] Such as Figure 1-3 As shown, a slurry separation system includes a feeding device 1 including a feeding bucket 11 and a feeding pipe 12, a cyclone desander device 2 including a slurry inlet pipe 21, a slurry outlet pipe 22 and a cyclone desander 23, including a vibration The flocculation sedimentation device 3 and the spiral separation device 4 of the screen 31, the sedimentation tank 32, and the spiral separation device 4 include the mud inlet pipe 41, the outer casing 42 containing the mud inlet 421, the middle bin 422 and the mud bin 423, and the first mud bin 423. Spiral blade 431, second spiral blade 432, input end 433 and conical screw 43 of shaft shoulder 435, filter sleeve 44, reduction motor 45, mud outlet 46 and water outlet 47; Wherein:

[0018] The feeding barrel 11 of the feeding device 1 is injected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com