Aluminum fluoride composite ceramic and preparation method thereof

A technology of composite ceramics and aluminum fluoride, which is applied in the field of ceramics, can solve the problems of flammability and explosion of raw materials and low fluoride ion content, and achieve the effect of increasing the content of fluoride ions and avoiding inflammability and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of aluminum fluoride composite ceramics that one embodiment of the present invention proposes, it comprises:

[0029] (1) AlF 3 、MF 2 , sintering aid TF and binder are mixed, and after ball milling, drying and sieving, aluminum fluoride mixture is obtained; among them, MF 2 for CaF 2 and MgF 2 At least one of; TF is at least one of LiF, NaF and KF;

[0030] Specifically, the AlF 3 and MF 2 Mix, then add TF sintering aid and binder.

[0031] In weight percent, AlF 3 : MF 2 =1:1~9:1, preferably 1:1, 7:3, 8:2 and 9:1.

[0032] Pure AlF 3 Due to the low decomposition temperature, it is difficult to densify, and MF needs to be added 2 To improve its decomposition problem and achieve densification; MF 2 The less, the lower the density, the higher the fluoride ion content; MF 2 The more, the higher the density and the lower the fluoride ion content.

[0033] By introducing MF 2 , TF and other additives to replace Al powder, the obvio...

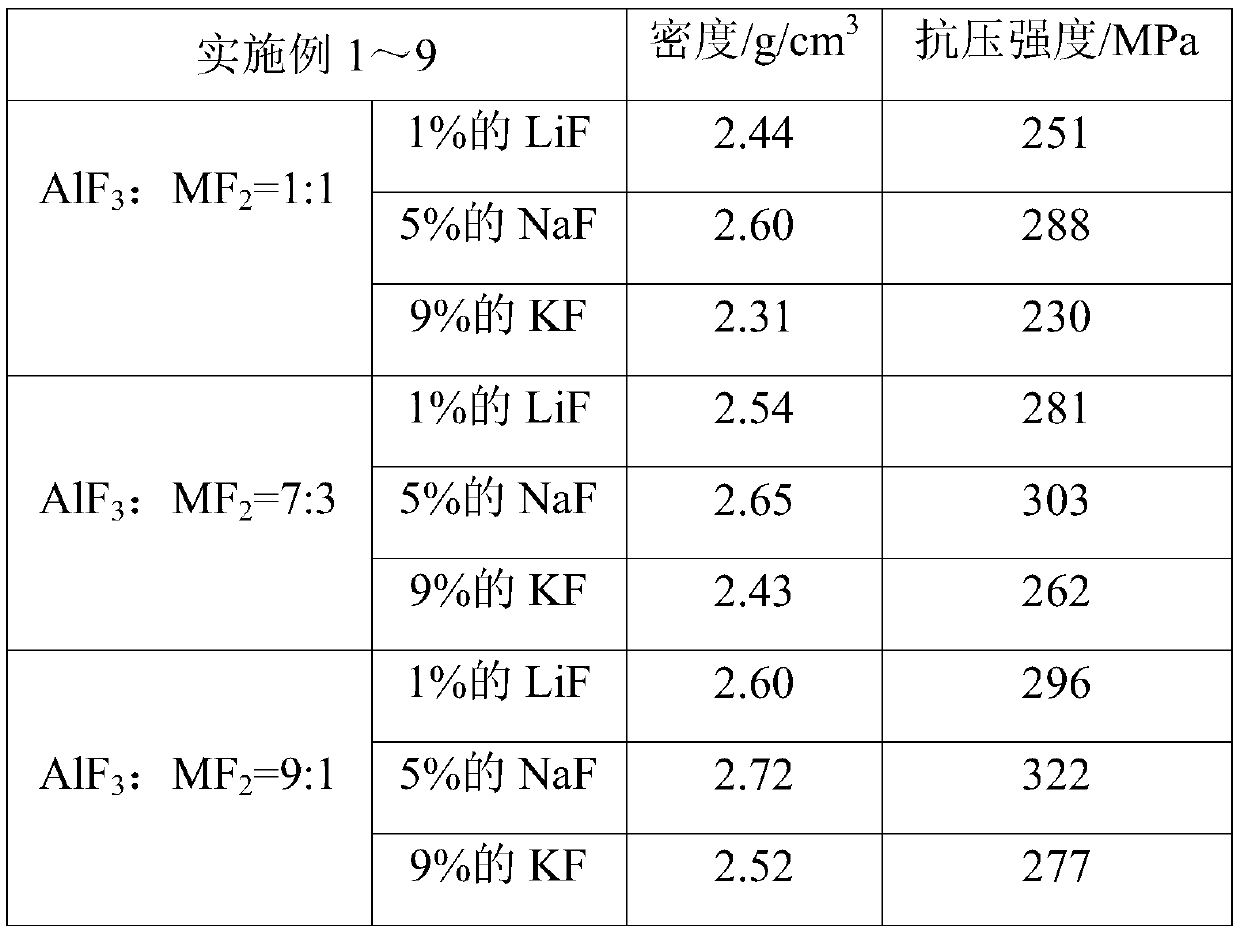

Embodiment 1~9

[0049] (1) With the raw material of aluminum fluoride composite ceramics listed in Table 1, AlF 3 、MF 2 , sintering aid TF and binder (optionally one of dextrin, starch, polyvinyl alcohol and gum arabic) are mixed, ball milled at a speed of 100-200r / min for 3-8h, naturally dried, using 30 mesh ~100 mesh for sieving to obtain aluminum fluoride mixture;

[0050] (2) Put the aluminum fluoride composite material into a rubber mold or a stainless steel mold, and perform dry pressing molding under a pressure of 30-100 MPa, or perform isostatic pressing molding under a pressure of 100-300 MPa to obtain an aluminum fluoride composite ceramic green body ;

[0051] (3) Sintering the aluminum fluoride composite ceramic green body, the sintering conditions: first raise the temperature to 600°C at a rate of 0.5°C / min-2°C / min, and keep the temperature at 600°C for 1-2h; The heating rate of ℃ / min~5℃ / min was raised from 600℃ to 800℃~950℃, and kept at 800℃~950℃ for 1~8h; the aluminum fluori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com