Polyacrylate, acrylic foam composition, acrylic foam adhesive tape as well as preparation methods and applications thereof

A technology of polyacrylate and acrylic foam, which is applied in the direction of adhesives, film/sheet adhesives, film/sheet release liners, etc. It can solve the problems of complex processing, high equipment requirements, and poor shockproof effect. , to achieve the effect of simple operation process, simple preparation method and accompanying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

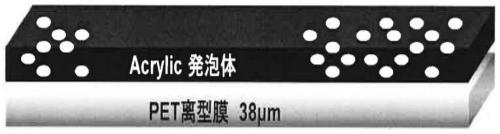

Image

Examples

Embodiment 1

[0041] 1. Preparation of polyacrylate:

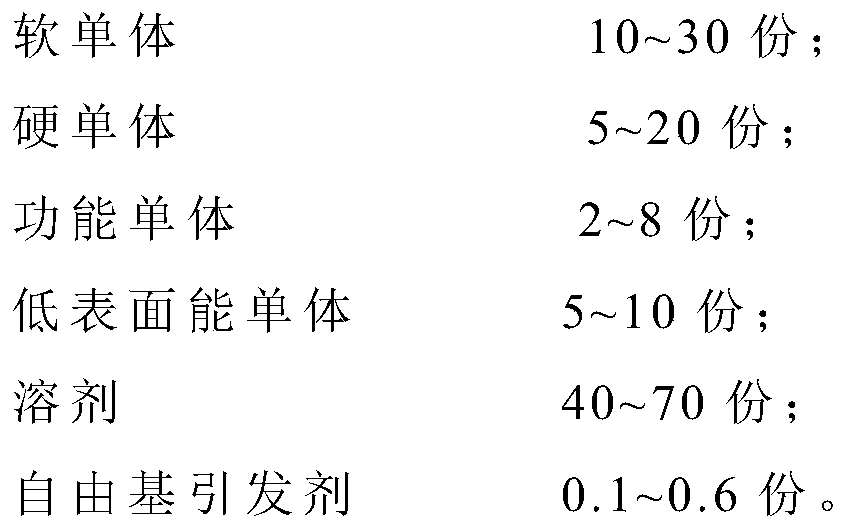

[0042] Polyacrylate comprises the raw material of following weight portion:

[0043]

[0044] Polyacrylate adopts the free radical thermal polymerization method, that is, after the soft monomer, hard monomer, functional monomer, special monomer and solvent are mixed evenly, nitrogen gas is introduced, and the free radical is added in three times after heating to 67-70°C. agent, after the reaction is finished, cool it for use.

[0045] 2. Acrylic foam coating solution

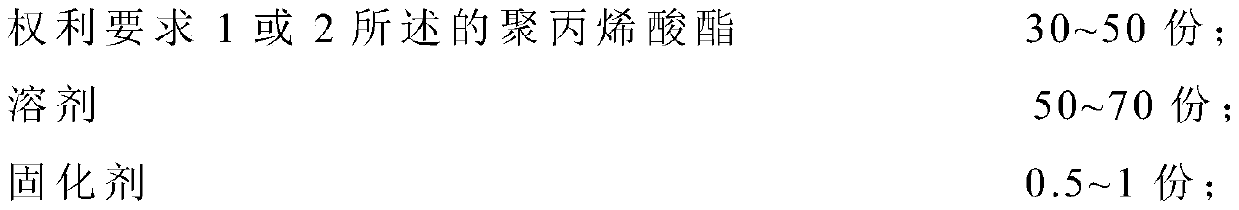

[0046] The acrylic foam coating solution comprises the following raw materials in parts by weight:

[0047]

[0048] 3. Preparation of acrylic foam tape:

[0049] (1), after mixing each raw material polyacrylate, solvent, curing agent, foaming microspheres, dispersant and carbon black in the acrylic foam coating liquid, stir to obtain the acrylic foam coating liquid;

[0050] (2), the acrylic foam coating liquid is coated on the PET release film by coating machine...

Embodiment 2

[0054] 1. Preparation of polyacrylate:

[0055] Polyacrylate comprises the raw material of following weight portion:

[0056]

[0057] Polyacrylate adopts the free radical thermal polymerization method, that is, soft monomers, hard monomers, functional monomers, special monomers and solvents are mixed evenly, then nitrogen gas is introduced, heated to 67-70°C, and free radicals are added in three times to initiate agent, after the reaction is finished, cool it for use.

[0058] 2. Acrylic foam coating solution

[0059] The acrylic foam coating solution comprises the following raw materials in parts by weight:

[0060]

[0061] 3. Preparation of acrylic foam tape:

[0062] (1), after mixing each raw material polyacrylate, solvent, curing agent, foaming microspheres, dispersant and carbon black in the acrylic foam coating liquid, stir to obtain the acrylic foam coating liquid;

[0063] (2), the acrylic foam coating liquid is coated on the PET release film by coating ma...

Embodiment 3

[0067] 1. Preparation of polyacrylate:

[0068] Polyacrylate comprises the raw material of following weight portion:

[0069]

[0070] Polyacrylate adopts the free radical thermal polymerization method, that is, soft monomers, hard monomers, functional monomers, special monomers and solvents are mixed uniformly, then nitrogen gas is passed through, and free radical initiators are added in 3 times after heating to 70°C. After the reaction is completed, cool it for later use.

[0071] 2. Acrylic foam coating solution

[0072] The acrylic foam coating solution comprises the following raw materials in parts by weight:

[0073]

[0074] 3. Preparation of acrylic foam tape:

[0075] (1), after mixing each raw material polyacrylate, solvent, curing agent, foaming microspheres, dispersant and carbon black in the acrylic foam coating liquid, stir to obtain the acrylic foam coating liquid;

[0076] (2), the acrylic foam coating liquid is coated on the PET release film by coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com