Waterproof emulsion with reinforced waterproof agent emulsion structure

A technology of waterproof emulsion and water repellent, applied in textiles, papermaking, fiber processing, etc., can solve the problems of weak emulsion stability of water repellent, damage of water repellent emulsification system, influence of waterproof performance, etc., to improve the stability of disperse dyes, The effect of improving anti-interference performance and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

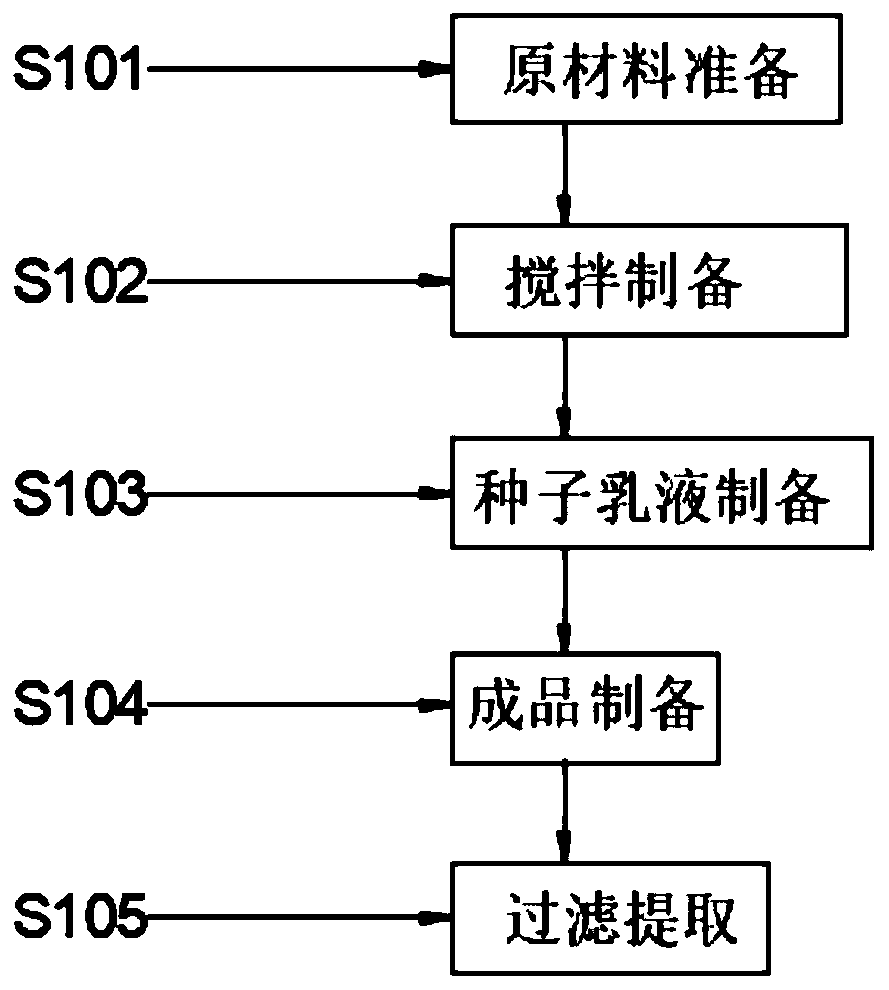

[0024] see figure 1 , the present invention provides following technical scheme:

[0025] A waterproof emulsion that strengthens the emulsified structure of a waterproof agent, specifically comprising the following components: 3.6% fluorine-containing acrylate copolymer, 0.6% emulsifier, 0.6% tripropylene glycol, 1% styrene, 0.2% acrylic acid, and 0% polyether compound , quaternary ammonium salt polymer compound 0%, polydimethylsiloxane 0%, deionized water 94% and pH regulator.

[0026] A method for preparing a waterproof emulsion that strengthens the emulsified structure of a waterproof agent, specifically comprising the following steps:

[0027] S101, raw material preparation: fluorine-containing acrylate copolymer, emulsifier, tripropylene glycol, styrene, acrylic acid, polyether compound, quaternary ammonium salt polymer compound, polydimethylsiloxane, deionized water and pH regulator Prepare the materials according to the components, prepare the preparation container an...

Embodiment 2

[0040] see figure 1 , the present invention provides following technical scheme:

[0041] A waterproof emulsion that strengthens the emulsified structure of a waterproof agent, specifically comprising the following components: 3.6% fluorine-containing acrylate copolymer, 0.6% emulsifier, 0.6% tripropylene glycol, 1% styrene, 0.2% acrylic acid, and 0.1% polyether compound , quaternary ammonium salt polymer compound 0%, polydimethylsiloxane 0%, deionized water 93.9% and pH regulator.

[0042] A method for preparing a waterproof emulsion that strengthens the emulsified structure of a waterproof agent, specifically comprising the following steps:

[0043] S101, raw material preparation: fluorine-containing acrylate copolymer, emulsifier, tripropylene glycol, styrene, acrylic acid, polyether compound, quaternary ammonium salt polymer compound, polydimethylsiloxane, deionized water and pH regulator Prepare the materials according to the components, prepare the preparation containe...

Embodiment 3

[0056] see figure 1 , the present invention provides following technical scheme:

[0057] A waterproof emulsion that strengthens the emulsified structure of a waterproof agent, specifically comprising the following components: 3.6% fluorine-containing acrylate copolymer, 0.6% emulsifier, 0.6% tripropylene glycol, 1% styrene, 0.2% acrylic acid, and 0.15% polyether compound , quaternary ammonium salt polymer compound 0%, polydimethylsiloxane 0%, deionized water 93.85% and pH regulator.

[0058] A method for preparing a waterproof emulsion that strengthens the emulsified structure of a waterproof agent, specifically comprising the following steps:

[0059] S101, raw material preparation: fluorine-containing acrylate copolymer, emulsifier, tripropylene glycol, styrene, acrylic acid, polyether compound, quaternary ammonium salt polymer compound, polydimethylsiloxane, deionized water and pH regulator Prepare the materials according to the components, prepare the preparation contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com