Super-hydrophobic three-dimensional porous material and preparation method thereof

A three-dimensional porous, super-hydrophobic technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of oil-water selectivity to be improved, insufficient stability, complicated introduction process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0052] ①Pretreatment of melamine sponge

[0053] Take 5 melamine sponge blocks of 30×20×20mm, wash them with distilled water and deionized water in turn, and then wash them with an appropriate amount of absolute ethanol in an ultrasonic cleaner for 3 times, each time for 30 minutes, to remove surface impurities, and then dry them naturally. spare.

[0054] ②MS / TiO 2 Synthesis

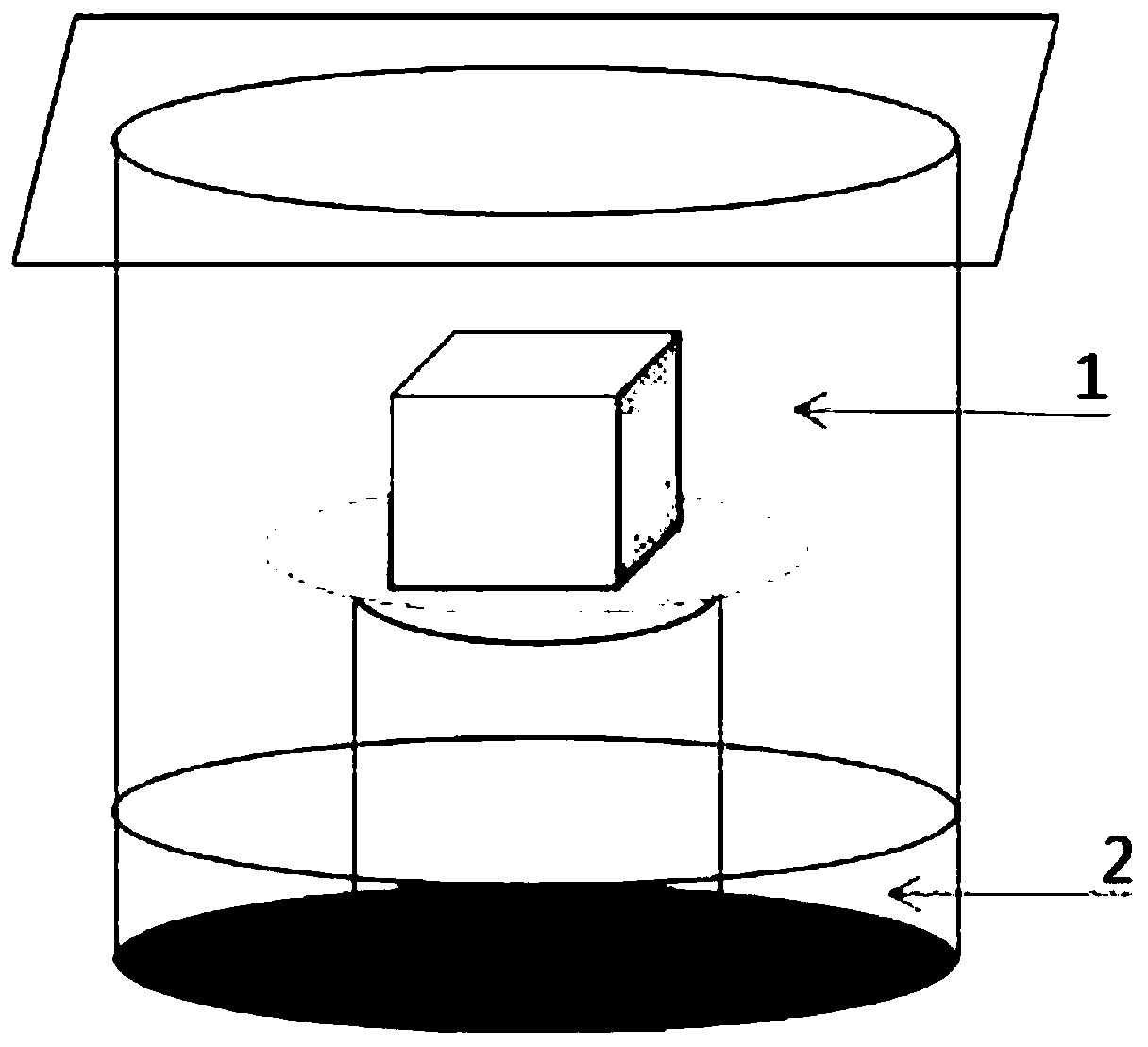

[0055] Using absolute ethanol as a solvent, prepare a TBOT / absolute ethanol solution with a concentration (volume fraction) of 20%, soak the pretreated sponge block in the above solution, take it out after soaking for 3.5 hours at room temperature, and place it in a container 1 / 3 of the container volume of water in a wet closed system for hydrolysis (see figure 1 ), take it out after 17 hours, then wash it three times with an appropriate amount of absolute ethanol, and let it dry naturally.

[0056] ③ MS / TiO 2 Synthesis of / PDMS

[0057] Using n-hexane as a solvent, prepare PDMS / n-hexane solutions...

Embodiment 5~9

[0058] ①Pretreatment of melamine sponge

[0059] Take 6 melamine sponge blocks of 30×20×20mm, wash them with distilled water and deionized water in turn, and then wash them with an appropriate amount of absolute ethanol in an ultrasonic cleaner for 3 times, each time for 30 minutes, to remove surface impurities, and then dry them naturally. spare.

[0060] ②MS / TiO 2 Synthesis

[0061] Using absolute ethanol as a solvent, the TBOT concentration (volume fraction) of the preparation is 5%, 10%, 15%, 20% and 25% TBOT / absolute ethanol solution successively, and the 5 sponge blocks after pretreatment are soaked in respectively In the above solution, take it out after immersing at room temperature for 3.5 hours, and then place it in a moist closed system filled with an appropriate amount of water for hydrolysis (for the device see figure 1 ), take it out after 17 hours, then wash it three times with an appropriate amount of absolute ethanol, and let it dry naturally. (the TBOT tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com