A kind of ceramic polishing fluid with core-shell structure

A technology of ceramic polishing and core-shell structure, applied in the field of ceramic materials, can solve the problems of reduced gloss, poor antifouling effect, agglomeration, etc., and achieve good flexibility and self-recovery performance, long-lasting antifouling effect, and good dimensional stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

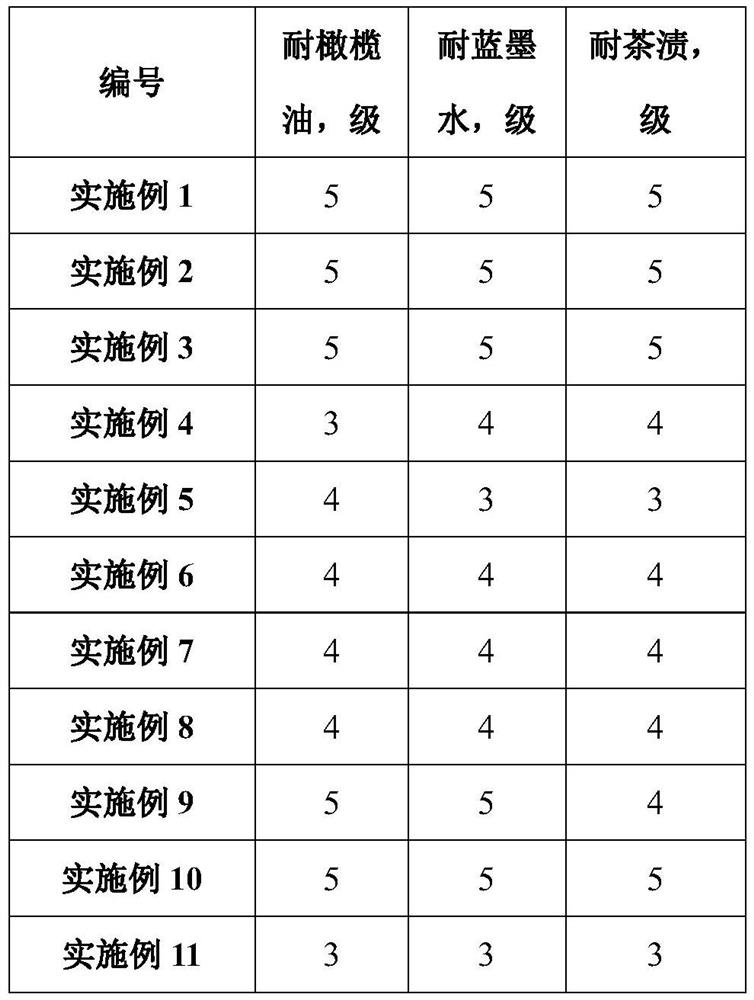

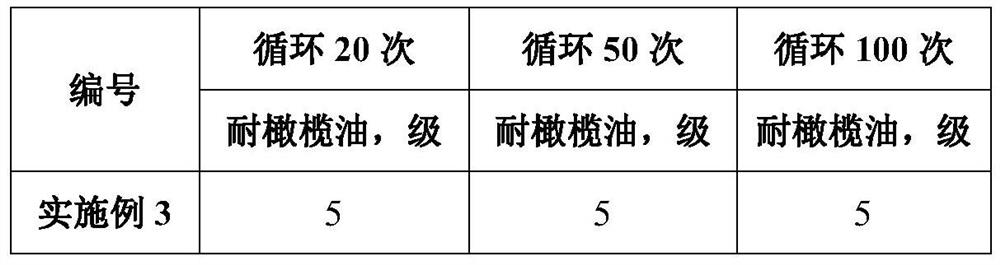

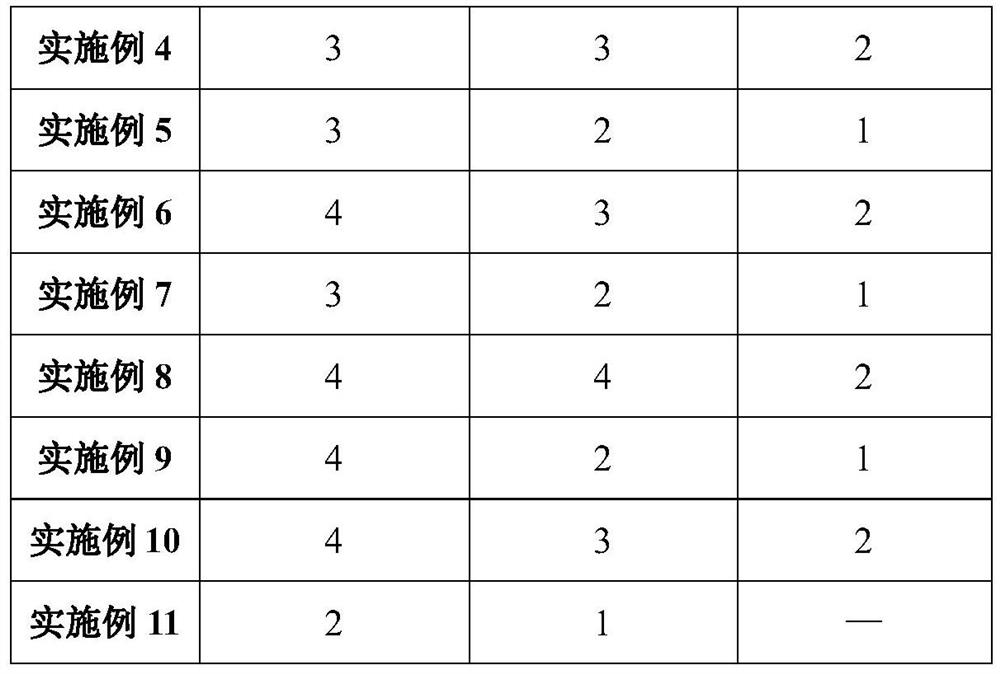

Examples

preparation example Construction

[0025] In some embodiments, the preparation method of the hybrid emulsion particle comprises the following steps:

[0026] (1) Add 3-methacrylic acid propyltrimethoxysilane to the solvent, disperse for 20-40 minutes, then add nano silicon dioxide, ultrasonically disperse at room temperature for 15-25 minutes, and react under nitrogen atmosphere for 8-12 hours , centrifuged, and the resulting solid is washed and dried to obtain pretreated nano-silica;

[0027] (2) Sodium lauryl sulfate is added in the reaction vessel that fills deionized water, adds described pretreatment nano silicon dioxide, stirs and disperses; Then add dropwise the mixed liquid of acrylate, lauryl alcohol, potassium persulfate, Stir at room temperature, then raise the temperature of the reaction system to 70-85°C and react for 1.5-2.5 hours, then add sodium dodecylbenzenesulfonate and continue stirring, react for 1-2 hours, the temperature of the system is lowered to room temperature, and the material is di...

Embodiment 1

[0048] This embodiment provides a ceramic polishing solution with a core-shell structure. According to parts by weight, the raw materials of the polishing solution include 30 parts of functional hybrid nanoparticles, 3 parts of water-based silicone glass resin, 5 parts of silica sol, emulsified 0.5 part of agent, 0.1 part of auxiliary agent, 30 parts of water;

[0049] The raw materials for the preparation of the functional hybrid nanoparticle body include hybrid emulsion particles and functional ligands, wherein the preparation method of the hybrid emulsion particles comprises the following steps: (1) in a mixed solvent with a mass ratio of water and methanol of 2:1 Add 1.4g of 3-methacrylic acid propyltrimethoxysilane, disperse for 30min, then add 1g of nano-silica with a particle size of 100nm, ultrasonically disperse at room temperature for 20min, and react at 60°C for 10 hours under a nitrogen atmosphere , centrifuged, the resulting solid was washed with ethanol and dried...

Embodiment 2

[0054] This embodiment provides a ceramic polishing solution with a core-shell structure. According to parts by weight, the raw materials of the polishing solution include 50 parts of functional hybrid nanoparticles, 7 parts of water-based silicone glass resin, 18 parts of silica sol, emulsified 1.2 parts of agent, 5 parts of auxiliary agent, 70 parts of water;

[0055] The raw materials for the preparation of the functional hybrid nanoparticle body include hybrid emulsion particles and functional ligands, wherein the preparation method of the hybrid emulsion particles comprises the following steps: (1) in a mixed solvent with a mass ratio of water and methanol of 2:1 Add 1.4g of 3-methacrylic acid propyltrimethoxysilane, disperse for 30min, then add 1g of nano-silica with a particle size of 100nm, ultrasonically disperse at room temperature for 20min, and react at 60°C for 10 hours under a nitrogen atmosphere , centrifuged, the resulting solid was washed with ethanol and drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com