Passivator for repairing soil heavy metal Cd pollution and preparation method thereof

A technology for repairing soil and heavy metals, applied in chemical instruments and methods, soil conditioning materials, applications, etc., can solve the problems of poor passivation repair effect, complex synthesis process, difficult to use on a large scale, etc., to make up for poor passivation effect, Simple synthesis process and small application amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

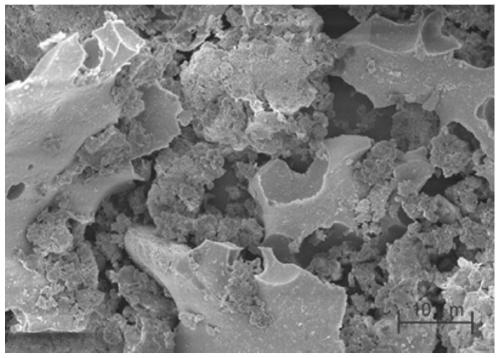

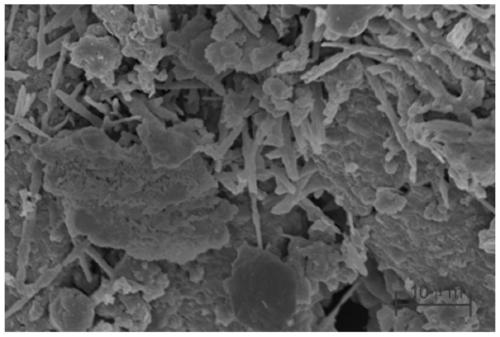

Image

Examples

Embodiment 1

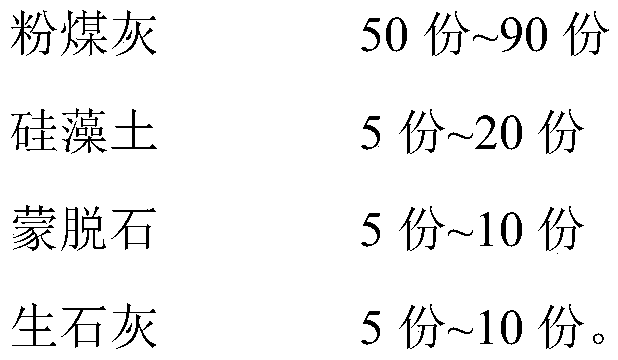

[0042] A passivator for remediating soil heavy metal Cd pollution, it is made of the following raw materials in parts by weight:

[0043]

[0044] Above-mentioned a kind of preparation method that is used to repair the passivator of soil heavy metal Cd pollution, it comprises the following steps:

[0045] Step 1. Treatment of diatomite: Put the formula amount of diatomite into the scrubbing machine, add water to adjust the mass concentration to 35%, stir evenly, then add sodium hexametaphosphate with a mass concentration of 0.5% to continue scrubbing for 30 minutes, and then The scrubbing product is diluted to a mass concentration of 10% under stirring conditions, and then passed through a 100-mesh sieve to remove weeds, large-grained quartz and feldspar, and then allowed to settle, and the precipitate is filtered and then dried and crushed in sequence and grinding through a 200-mesh sieve to obtain treated diatomite; in the present embodiment, the drying temperature is 105...

Embodiment 2

[0053] A passivator for remediating soil heavy metal Cd pollution, it is made of the following raw materials in parts by weight:

[0054]

[0055] Above-mentioned a kind of preparation method that is used to repair the passivator of soil heavy metal Cd pollution, it comprises the following steps:

[0056] Step 1. Treatment of diatomite: Put the formula amount of diatomite into the scrubbing machine, add water to adjust the mass concentration to 30%, stir evenly, then add sodium hexametaphosphate with a mass concentration of 0.3% to continue scrubbing for 20 minutes, and then Dilute the scrubbing product to a mass concentration of 7% under stirring conditions, and then pass through an 80-mesh sieve to remove weeds, large-grained quartz and feldspar, and then let it stand for precipitation, filter the sediment, and then dry and pulverize it in turn and grinding through a 180 mesh sieve to obtain treated diatomite; in the present embodiment, the drying temperature is 100°C;

...

Embodiment 3

[0064] A passivator for remediating soil heavy metal Cd pollution, it is made of the following raw materials in parts by weight:

[0065]

[0066] Above-mentioned a kind of preparation method that is used to repair the passivator of soil heavy metal Cd pollution, it comprises the following steps:

[0067] Step 1. Treatment of diatomite: put the formula amount of diatomite into the scrubbing machine, add water to adjust the mass concentration to 40%, stir evenly, then add sodium hexametaphosphate with a mass concentration of 0.8% to continue scrubbing for 40 minutes, and then Dilute the scrubbing product to a mass concentration of 13% under stirring conditions, and then pass it through a 120-mesh sieve to remove weeds, large-grained quartz and feldspar, and then let it stand for precipitation, filter the sediment, and then dry and pulverize it in turn and grinding through a 220 mesh sieve to obtain treated diatomite; in the present embodiment, the drying temperature is 110°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com