A method for improving the electro-oxidation and anti-poisoning performance of methanol fuel cells

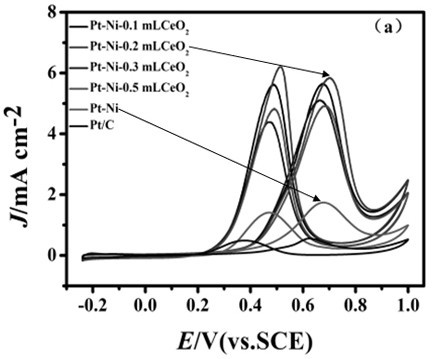

A methanol fuel cell and electro-oxidation technology, which is applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of easy poisoning and low utilization efficiency per unit mass, achieve lively properties, promote anti-poisoning ability, and improve electricity The effect of catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

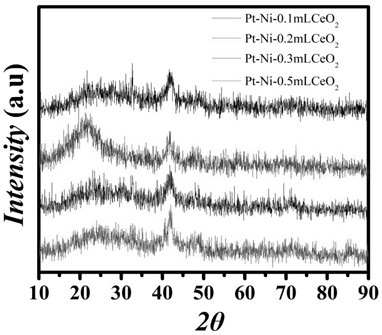

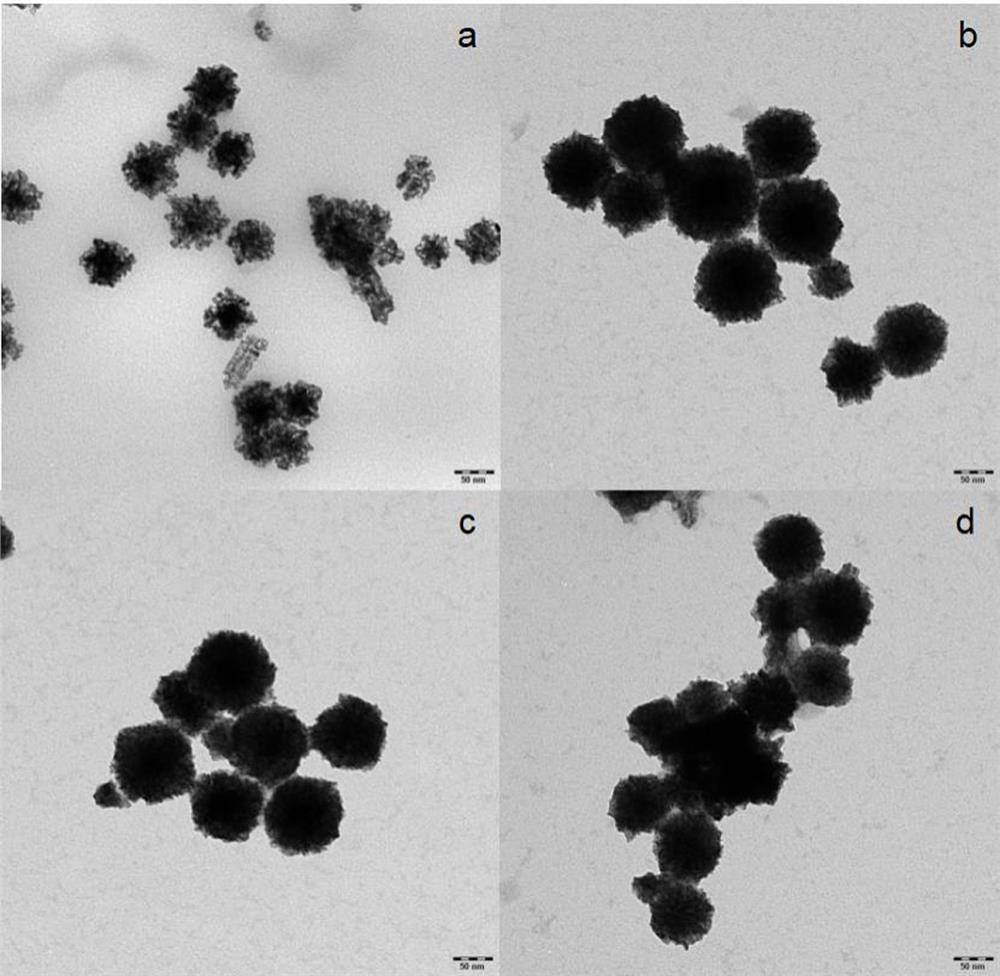

[0028] A Pt-Ni Binary Alloy Supporting CeO 2 The experimental steps of the preparation method are as follows:

[0029] (1) 1mL oleylamine corresponds to 3.44mg CeO 2 Add (a) 0mL (b) 0.1mL (c) 0.2mL and (d) 0.3mL respectively to the centrifuge tube, centrifuge once at 10000r / min for 15min, and absorb the supernatant with a pipette gun liquid until only the precipitate remains;

[0030] (2) Weigh 8mg platinum acetylacetonate and 12mg nickel acetylacetonate respectively in a clean beaker;

[0031] (3) Use a graduated cylinder to measure 9 mL of oleylamine and add it to the beaker in (2), pipette 1000 μL of oleic acid into the beaker, sonicate for 10 minutes until the solution is clear, and stir for 30 minutes;

[0032] (4) Pipette 800 μL (40%) formaldehyde solution, slowly drop it into the beaker, and continue to stir for 15 minutes until the solution is clear;

[0033] (5) Pipette 1ml of the clear and transparent solution into the centrifuge tube of step (1), disperse evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com