Pore refining essence and production method thereof

A pore astringent and essence technology, which is applied in the field of skin care products, can solve problems such as poor astringent effect, inability to repair and improve damaged skin, and single efficacy, and achieve the effects of improving pore astringency, regulating oil secretion, and improving health status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

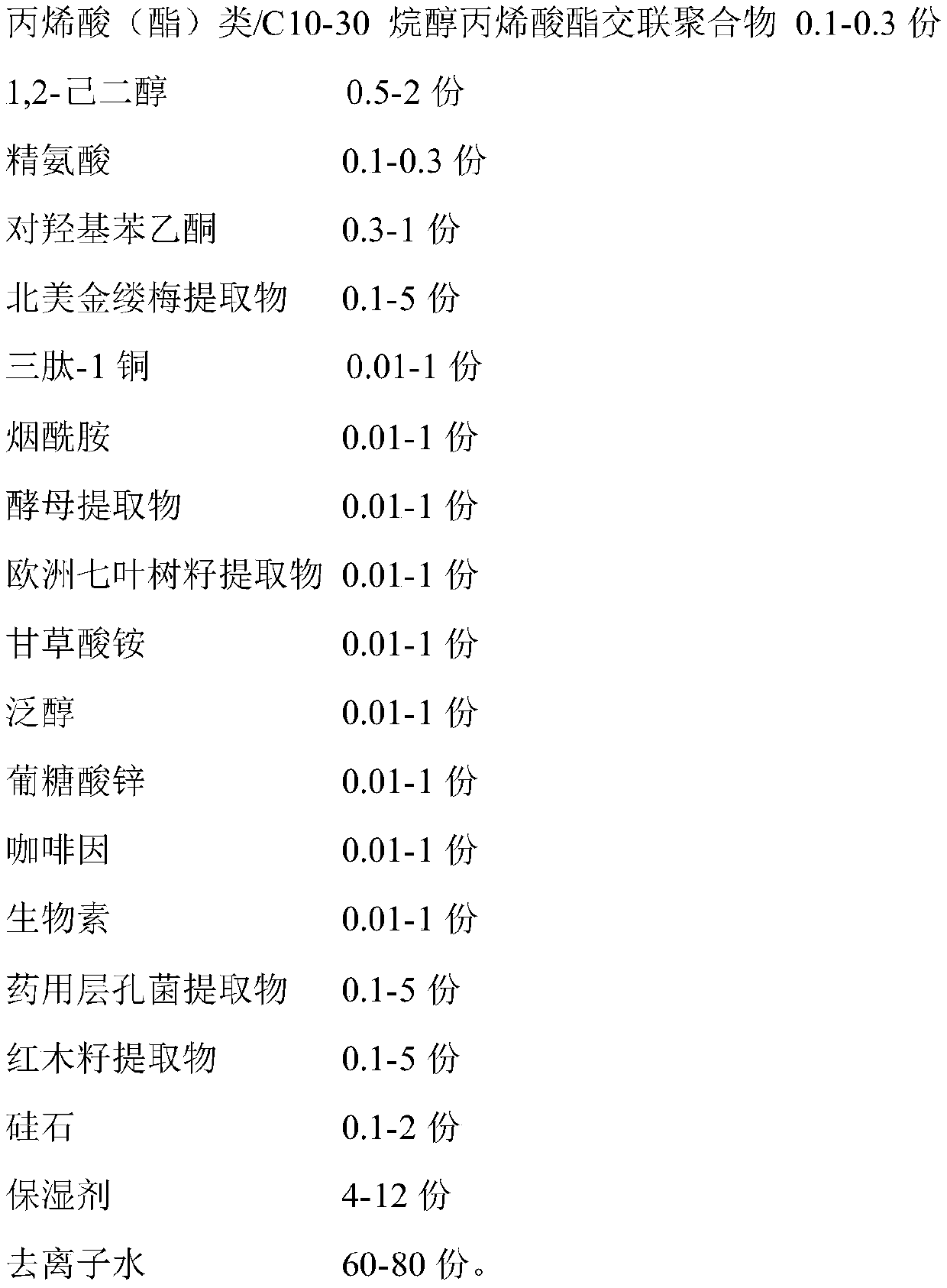

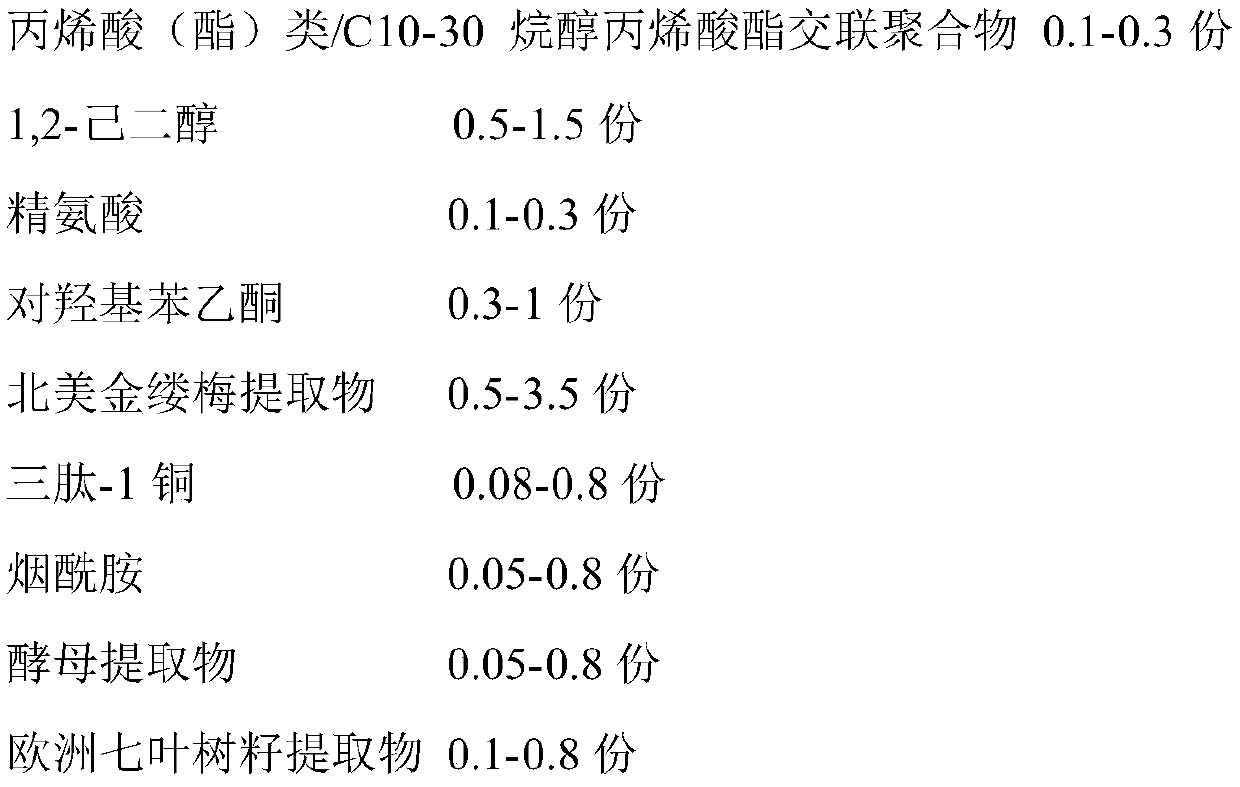

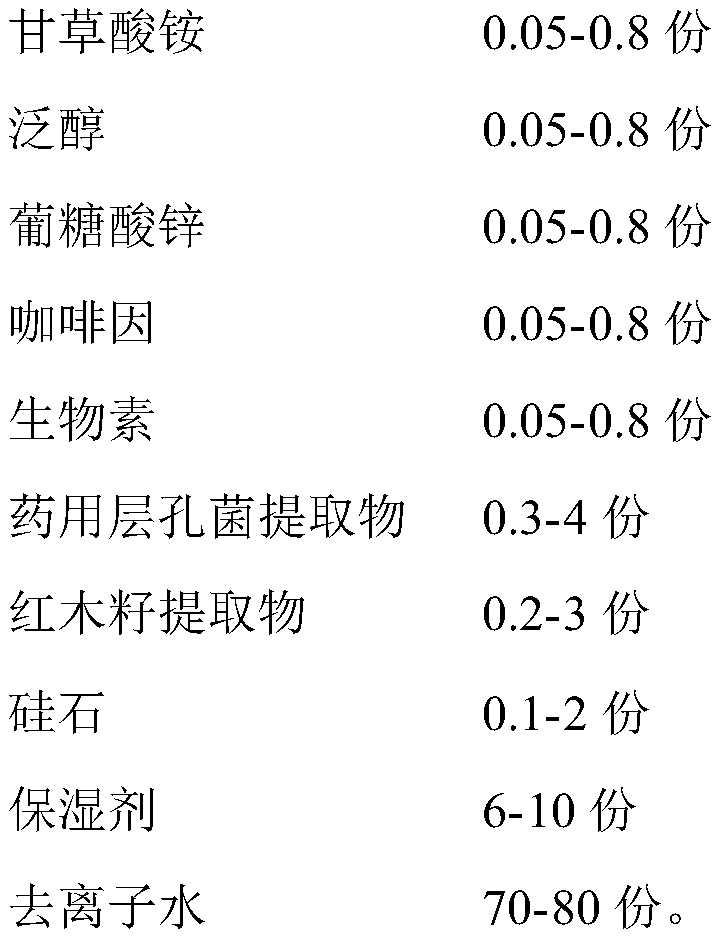

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of a kind of pore tightening essence of the present embodiment comprises the following steps (the following dosages are all in parts by weight):

[0035] Step a. Add 79.37 parts of deionized water into the emulsification pot, and then evenly sprinkle 0.2 parts of acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer on the surface, and let it settle;

[0036] Step b. Heat the emulsification pot to 85°C, keep it warm for 30 minutes, and stir properly, and then add 0.6 parts of 1,2-hexanediol, 0.6 parts of p-hydroxyacetophenone, and 0.15 parts of pre-dispersed 6 parts of butanediol Add sodium hyaluronate, 1 part of trehalose and 2 parts of β-glucan into the emulsification pot homogeneously, homogenize for 6 minutes, stop heating until there are no particles, and then carry out vacuum defoaming for 20 minutes;

[0037] Step c, cool down to 60°C, add 0.2 parts of arginine, and stir evenly;

[0038] Step d, cool down to 45°C, add 1.5 parts ...

Embodiment 2

[0041] The preparation method of a kind of pore tightening essence of the present embodiment comprises the following steps (the following dosages are all in parts by weight):

[0042] Step a. Add 77.5 parts of deionized water into the emulsification pot, and then sprinkle 0.3 parts of acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer evenly on the surface, and let it settle;

[0043] Step b. Heat the emulsification pot to 85°C, keep it warm for 30 minutes, stir properly, and then add 0.5 parts of 1,2-hexanediol, 0.3 parts of p-hydroxyacetophenone, and 0.05 parts of pre-dispersed 8 parts of butanediol Add sodium hyaluronate, 0.5 parts of trehalose and 0.5 parts of β-glucan into the emulsification pot homogenously, homogenize for 8 minutes, stop heating until there are no particles, and then carry out vacuum defoaming for 20 minutes;

[0044] Step c, cool down to 55°C, add 0.3 parts of arginine, and stir evenly;

[0045] Step d, cool down to 45°C, add 3 parts of ...

Embodiment 3

[0048] The preparation method of a kind of pore tightening essence of the present embodiment comprises the following steps (the following dosages are all in parts by weight):

[0049]Step a. Add 75.4 parts of deionized water into the emulsification pot, and then sprinkle 0.1 part of acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer evenly on the surface, and let it settle;

[0050] Step b. Heat the emulsification pot to 85°C, stir properly, and then add 2 parts of 1,2-hexanediol, 0.8 parts of p-hydroxyacetophenone, and 0.2 parts of hyaluronic acid dispersed in advance with 3 parts of butanediol Add sodium, 2 parts of trehalose and 3 parts of β-glucan into the emulsification pot homogeneously, homogenize for 5 minutes, stop heating until there are no particles, and then carry out vacuum defoaming for 25 minutes;

[0051] Step c, cool down to 65°C, add 0.1 part of arginine, and stir evenly;

[0052] Step d, cool down to 42°C, add 0.5 part of Hamamelis hamamelis e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com