Eddy current powder separator for 3d printing metal powder classification

A metal powder and 3D printing technology, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve problems such as complex structure, sieve blockage, poor fluidity, etc., and achieve improved airflow rotation Strength, strong airflow force, and the effect of improving the classification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the eddy current powder classifier for 3D printing metal powder classification described here is a preferred embodiment, which is only used to illustrate and explain the present invention, and does not constitute a limitation to the present invention.

[0023] Example Eddy current powder classifier for 3D printing metal powder classification

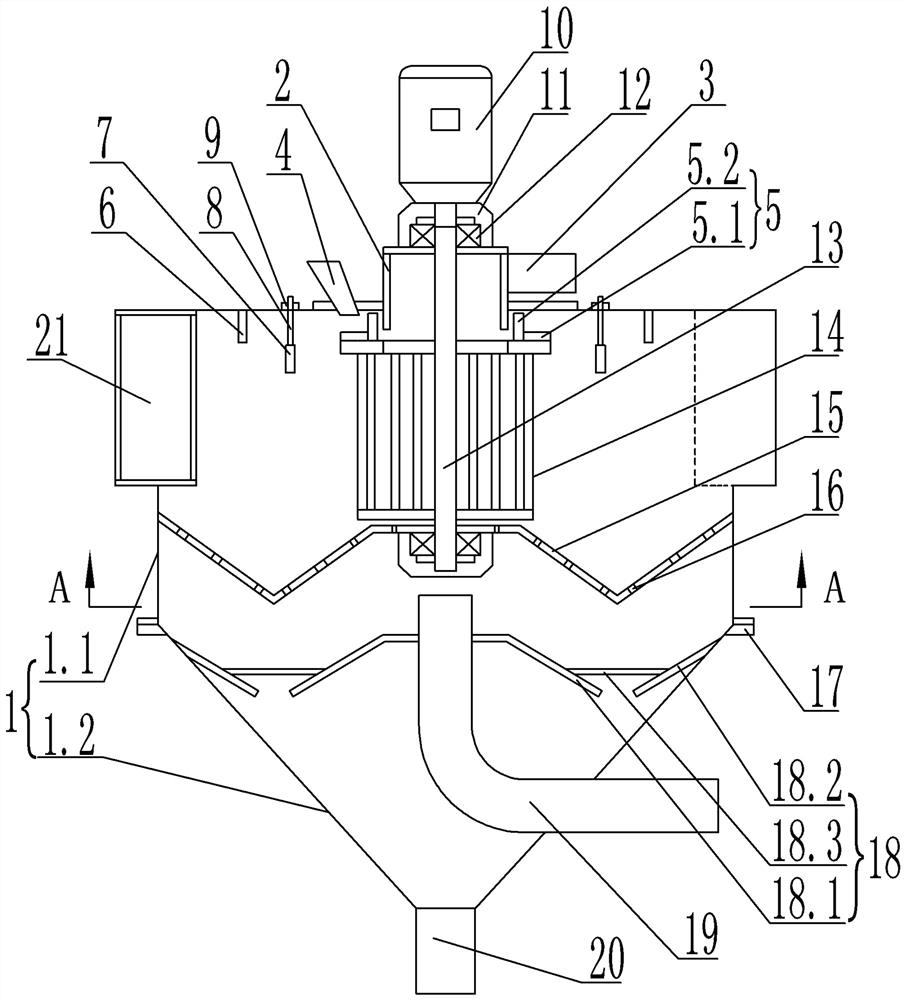

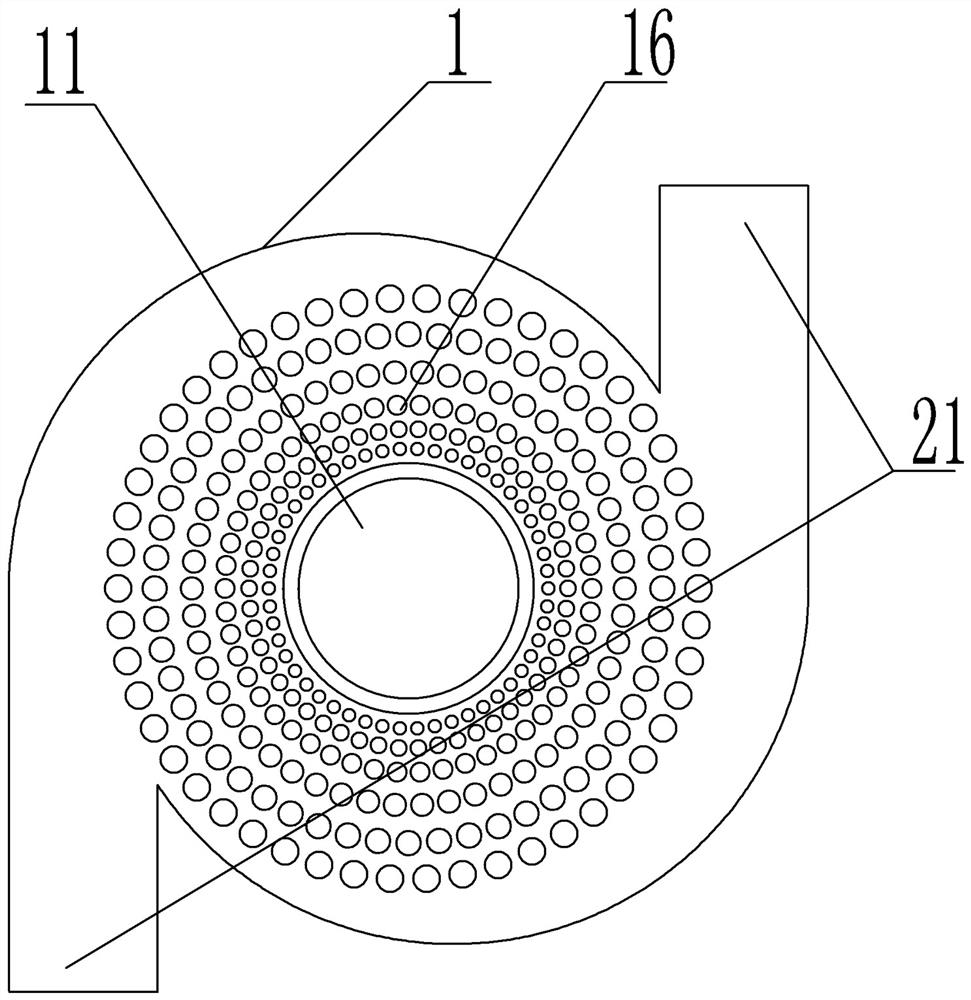

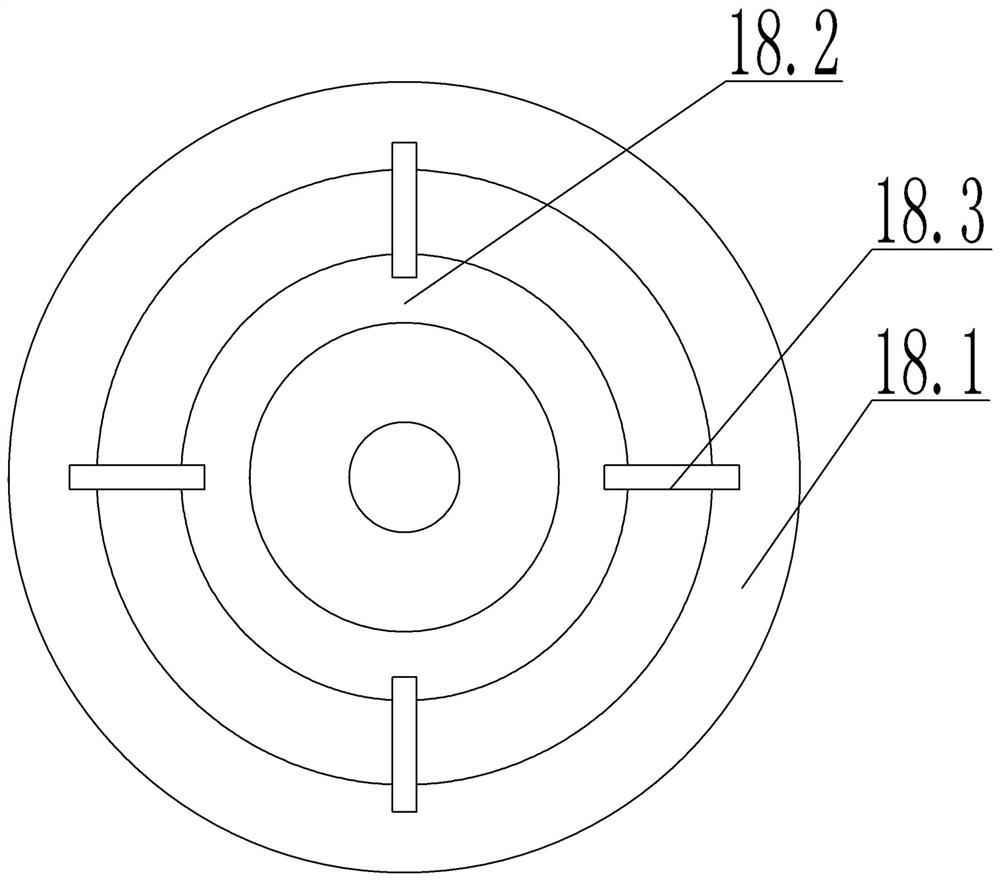

[0024] This example figure 1 , figure 2 , image 3 As shown, an eddy current powder separator for 3D printing metal powder classification includes a powder selection chamber 1, and the powder selection chamber 1 includes an upper part ( figure 1 upper) cylinder 1.1 and lower ( figure 1 Lower part) cone 1.2, the cone 1.2 is detachably connected to the cylinder 1.1 through the flange 17, the small-diameter end of the cone 1.2 is fixed with a coarse powder outlet 20, and the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com