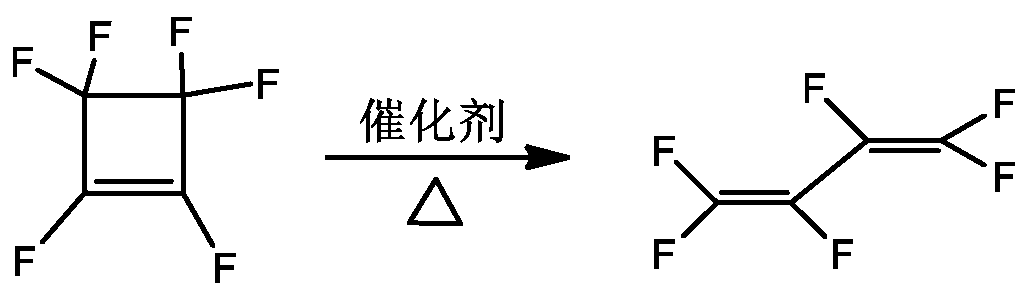

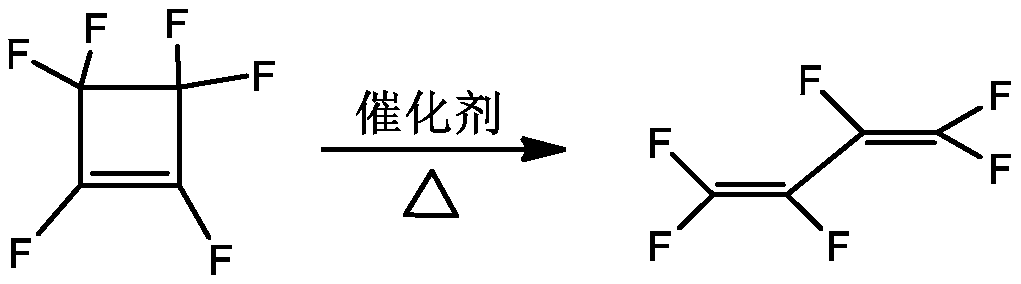

Method for synthesizing hexafluoro-1,3-butadiene through gas-phase catalytic isomerization

A technology of isomerization of hexafluorobutadiene, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., to achieve the effects of safe synthesis process, high yield, and simple technical route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of catalyst: adopt loading method, the steps are as follows: 5.0gNiCl 3 Dissolve in 100ml of deionized aqueous solution, and quickly pour the above solution into the dried alumina. After impregnating for 5 hours, the water was slowly drained using a rotary evaporator to obtain Ni / Al 2 o 3 catalyst.

[0022] Ni / Al 2 o 3 Catalyst drying process: 40mlNi / Al 2 o 3 The catalyst is loaded into the fixed bed reactor, and then the fixed bed reactor is heated with an open tube heating furnace. make Ni / Al 2 o 3 Under the protection of 50ml / min nitrogen, the catalyst is first raised to 400°C at a rate of 10°C / min and dried for 10 hours, and then the temperature is lowered to 200°C, thereby completing the Ni / Al 2 o 3 Catalyst drying process.

[0023] Ni / Al 2 o 3 Catalyst activation process: heat the fixed bed reactor to 200°C, first use 100ml / min nitrogen and 20ml / min hydrogen fluoride to activate and catalyze for 4 hours; then use 100ml / min nitrogen and...

Embodiment 2

[0026] The preparation of catalyst: adopt loading method, step is as follows: 4.75gMgCl 2 Dissolve in 100ml of deionized water solution, and quickly pour the above solution into 100g of dried alumina. After impregnating for 5 hours, the water was slowly drained using a rotary evaporator to obtain the Mg / Al 2 o 3 catalyst.

[0027] Mg / Al 2 o 3 Catalyst drying process: 40mlMg / Al 2 o 3 The catalyst is loaded into the fixed bed reactor, and then the fixed bed reactor is heated with an open tube heating furnace. Make Mg / Al 2 o 3 Under the protection of 50ml / min nitrogen, the catalyst is first raised to 400°C at a rate of 10°C / min and dried for 10 hours, then the temperature is lowered to 200°C, thus completing the Mg / Al 2 o 3 Catalyst drying process.

[0028] Mg / Al 2 o 3 Catalyst activation process: heat the fixed bed reactor to 200°C, first use 100ml / min nitrogen and 20ml / min difluorodichloromethane to activate and catalyze for 4 hours; then use 100ml / min nitrogen and...

Embodiment 3

[0031] The preparation of catalyst: adopt loading method, the steps are as follows: 6.30gNiCl 3 and 2.22g CaCl 2 Dissolve in 100ml of deionized aqueous solution, and quickly pour the above solution into 100g of molecular sieves that have been dried. After impregnating for 5 hours, the water was slowly drained using a rotary evaporator to obtain a Ni-Ca / MS catalyst.

[0032] The drying process of Ni-Ca / MS catalyst: 40ml of Ni-Ca / MS catalyst was loaded into the fixed-bed reactor, and then the fixed-bed reactor was heated with an open tube heating furnace. Under the protection of 50ml / min nitrogen, the Ni-Ca / MS catalyst is first raised to 400°C at a rate of 10°C / min and dried for 10 hours, and then the temperature is lowered to 200°C, thus completing the Ni-Ca / MS catalyst drying process.

[0033]Activation process of Ni-Ca / MS catalyst: Heat the fixed-bed reactor to 200°C, first use 100ml / min nitrogen and 20ml / min difluorochloromethane to activate and catalyze for 4 hours; then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com