Water-based two-component polyurethane paint for galvanized plates and preparation method of water-based two-component polyurethane paint

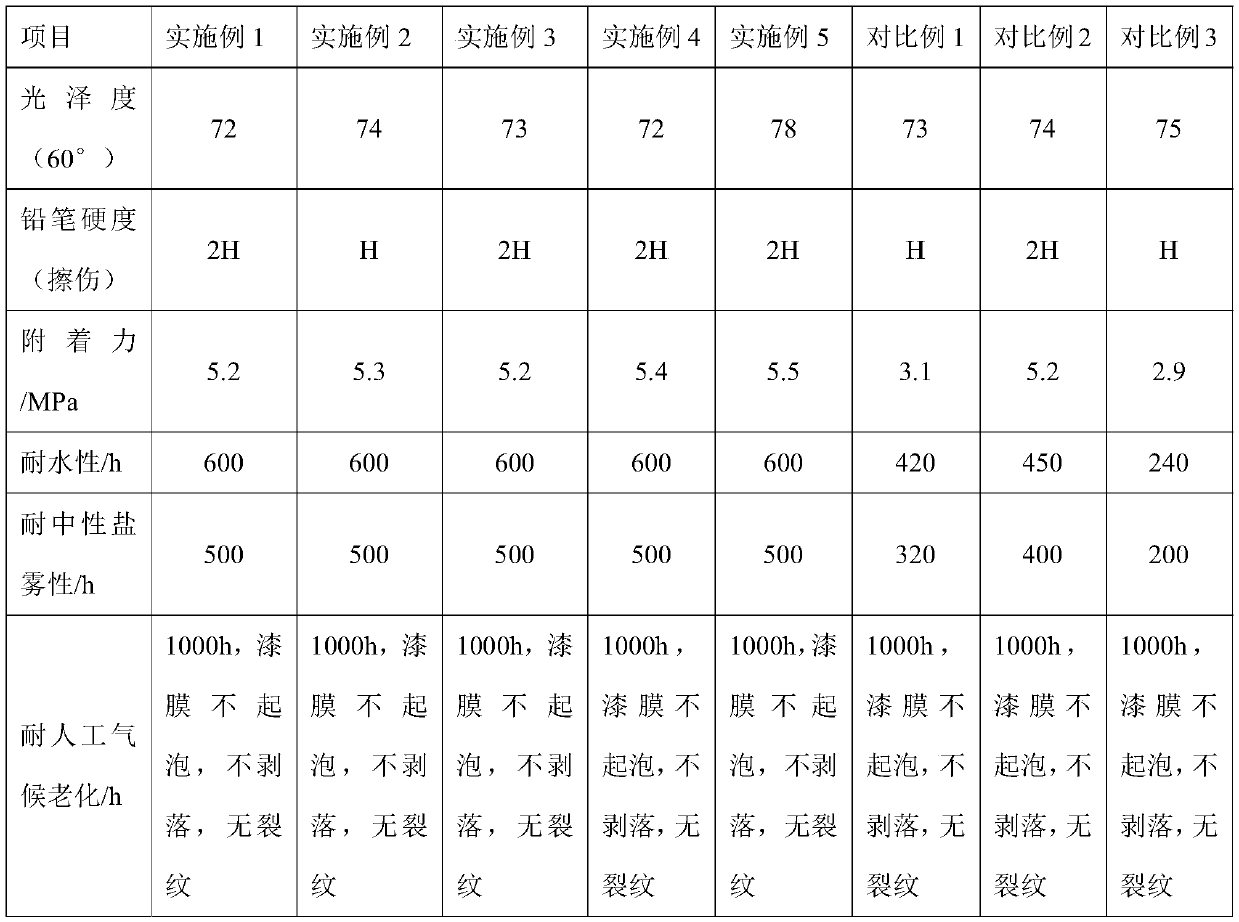

A two-component polyurethane and water-based isocyanate technology, applied in the field of coatings, can solve the problems of poor weather resistance and poor adhesion, and achieve the effects of good adhesion, good water resistance and excellent water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This example is a water-based two-component polyurethane coating, including A component and B component, the mass ratio of A component and B component is 8:1, and the compositions of A component and B component are as follows:

[0045] Component A includes the following components in parts by mass: 53 parts of aqueous hydroxyacrylic acid dispersion, 0.8 part of wetting and dispersing agent, 1 part of defoamer, 0.5 part of pH regulator, 6 parts of cosolvent, 25 parts of pigment and filler, 1 part of leveling agent, 1 part of thickener, 1.5 parts of adhesion promoter and 10 parts of deionized water;

[0046] B component is water-based isocyanate curing agent.

[0047] The raw materials used are described as follows:

[0048] Waterborne hydroxyacrylic acid dispersion: Antkote 2035 hydroxyacrylic acid dispersion of Yantai Wanhua Group Co., Ltd.;

[0049] Curing agent: WL72-100 from Asahi Kasei, Japan;

[0050] Wetting and dispersing agent: Digo 750w wetting and dispersin...

Embodiment 2

[0064] This example is a water-based two-component polyurethane coating, which includes component A and component B. The mass ratio of component A to component B is 8.2:1. The compositions of component A and component B are as follows:

[0065] Component A includes the following components in parts by mass: 58 parts of aqueous hydroxyacrylic acid dispersion, 0.8 part of wetting and dispersing agent, 1 part of defoamer, 0.5 part of pH regulator, 5 parts of cosolvent, 25 parts of pigment and filler, 1 part of leveling agent, 0.8 parts of thickener, 1.5 parts of adhesion promoter and 6 parts of deionized water.

[0066] B component is water-based isocyanate curing agent.

[0067] The raw materials used are described as follows:

[0068] Waterborne hydroxyacrylic acid dispersion: Antkote 2035 hydroxyacrylic acid dispersion of Yantai Wanhua Group Co., Ltd.;

[0069] Curing agent: WL72-100 from Asahi Kasei, Japan;

[0070] Wetting and dispersing agent: Digo 750w wetting and dispe...

Embodiment 3

[0084] This example is a water-based two-component polyurethane coating, including A component and B component, the mass ratio of A component and B component is 7:1, and the compositions of A component and B component are as follows:

[0085] Component A, including the following components in parts by mass: 50 parts of water-based hydroxyacrylic acid dispersion, 0.8 parts of wetting and dispersing agent, 1 part of defoamer, 0.5 parts of pH regulator, 5 parts of cosolvent, 25 parts of pigments and fillers, 1 part of leveling agent, 1 part of thickener, 1.5 parts of adhesion promoter and 14 parts of deionized water.

[0086] B component is water-based isocyanate curing agent.

[0087] The raw materials used are described as follows:

[0088] Waterborne hydroxyacrylic acid dispersion: Antkote 2035 hydroxyacrylic acid dispersion of Yantai Wanhua Group Co., Ltd.;

[0089] Curing agent: WL72-100 from Asahi Kasei, Japan;

[0090] Wetting and dispersing agent: Digo 750w wetting and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pencil hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com