Epoxy adhesive fast curable at room temperature and preparation method thereof

An epoxy adhesive, fast curing technology, applied in the direction of adhesive, epoxy resin, adhesive type, etc., can solve the problems of restricting production efficiency, slow strength improvement, short operation time, etc., to achieve rapid strength improvement capability, Appropriate operating time, enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

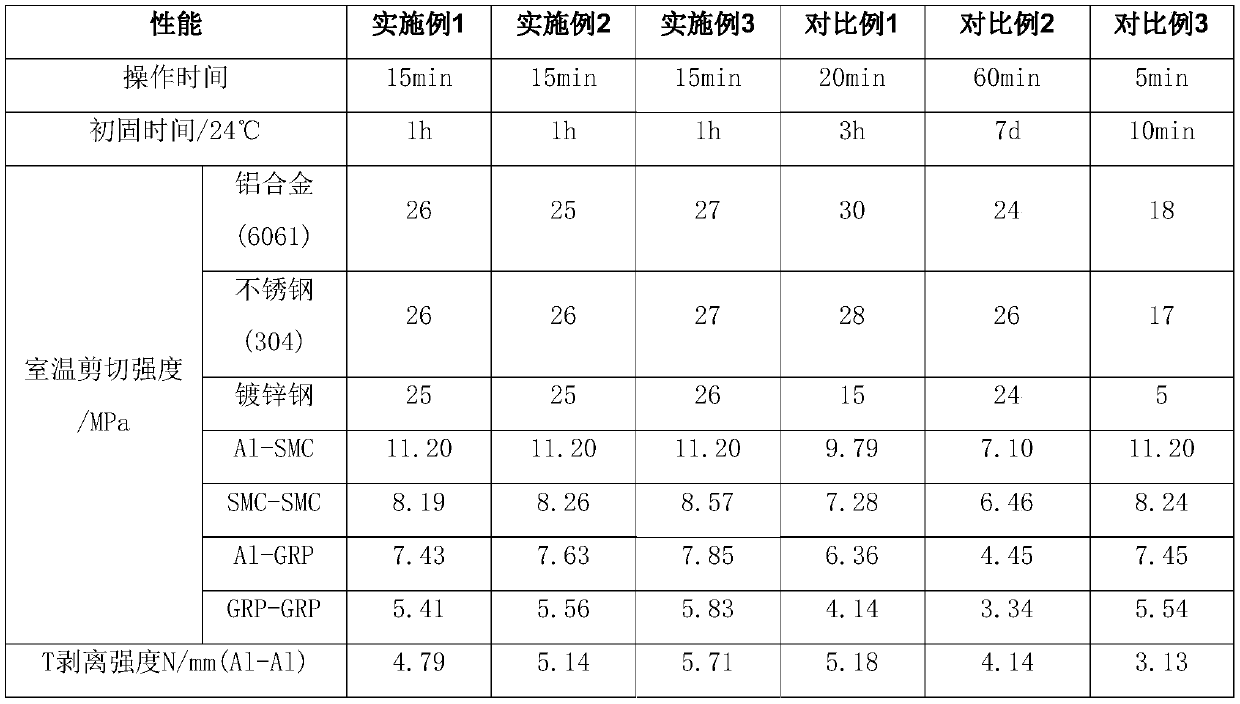

Examples

Embodiment approach

[0033] (1) The epoxy resin is at least one of bisphenol A type epoxy resin and bisphenol F type epoxy resin. The bisphenol A type epoxy resin adopts at least one of epoxy resin E-44, epoxy resin E-51, and epoxy resin E-54. The bisphenol F epoxy resin is at least one of epoxy resin F-51 and epoxy resin F-44.

[0034] (2) The flexible epoxy resin is at least one of flexible epoxy resin NPER-174, flexible epoxy resin YD-171, flexible epoxy resin NPER-133L, and flexible epoxy resin GY 298.

[0035](3) The toughening agent in component A adopts at least one of Qishi toughening agent and core-shell toughening agent; the toughening agent in component B adopts amino-terminated nitrile rubber and Qishi toughening agent at least one of the The Qishi toughening agent is at least one of Qishi toughening agent VL-4 and Qishi toughening agent VL-1; the core-shell toughening agent is formed by uniformly dispersing core-shell rubber in epoxy resin of blends. The core-shell rubber is a pol...

Embodiment 1

[0054] A kind of room temperature rapid curing epoxy adhesive, its preparation method comprises the following steps (each raw material is by weight):

[0055] Preparation of component A: Add 80 parts of epoxy resin E-51, 20 parts of flexible epoxy resin NPER-174, 50 parts of core-shell toughening agent, and 4 parts of coupling agent sj-42 into the reactor at room temperature Stirring, the planetary speed is 15-20Hz, the dispersion speed is 650rpm, vacuum is required during the stirring process, and the pressure is kept between -0.095--0.1MPa; after stirring for 30min, the dispersion speed is reduced to 250rpm, and 30 parts of calcium carbonate, 20 parts of barium sulfate whiskers, 4 parts of hydrophobic fumed silica, and then increase the dispersion speed to 650rpm, vacuumize, and keep the pressure between -0.095~-0.1MPa; stir for 2h, and clean the kettle every 30min during the period. Ensure the uniform dispersion of calcium carbonate, barium sulfate whiskers and hydrophobic ...

Embodiment 2

[0059] A kind of room temperature rapid curing epoxy adhesive, its preparation method comprises the following steps (each raw material is by weight):

[0060] Preparation of component A: 45 parts of epoxy resin E-44, 30 parts of epoxy resin F-51, 25 parts of flexible epoxy resin YD-171, 40 parts of core-shell toughening agent, 10 parts of Qishi toughening agent Add VL-4, 4 parts of coupling agent A172 into the reaction kettle and stir at room temperature. The planetary speed is 15-20Hz, and the dispersion speed is 650rpm. Vacuum is required during the stirring process, and the pressure is kept between -0.095~-0.1MPa. ; After stirring for 30 minutes, reduce the dispersion speed to 250 rpm, add 30 parts of alumina, 20 parts of barium sulfate whiskers, and 4 parts of hydrophobic fumed silica, then increase the dispersion speed to 650 rpm, vacuumize, and keep the pressure at -0.095 Between ~-0.1MPa; Stir for 2 hours, clear the kettle every 30 minutes during this period, to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com